Formaldehyde degradation experiment chamber, experimental method and application for degrading formaldehyde by using photocatalyst

A formaldehyde degradation and photocatalyst technology, applied in the field of formaldehyde degradation experiment chamber, can solve the problems of low activity of finished catalyst, low doping efficiency, poor universality, etc., and achieve the effects of simple structure, high doping efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The experimental steps of photocatalytic degradation of formaldehyde in indoor air are as follows:

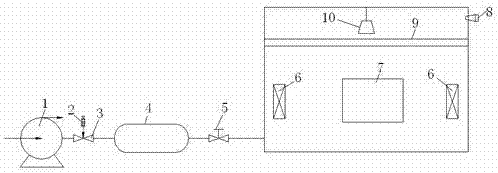

[0020]Step 1. The experiment is carried out in the self-made experimental cabin (Figure 1). The size of the experimental cabin is: 800×400×400 (mm), the material is 1mm thick stainless steel material, and the whole is welded and sealed. One inlet hole and one injection hole are respectively reserved in the experimental cabin, which are sealed with rubber pads. One designed cabin door, the size is 150mm×150mm, the light source is illuminated by fluorescent tubes, and the initial value of formaldehyde is not greater than 1.5 mg / m 3 , the light source suspension device and the sample holder are installed in the experimental cabin. In addition, two small fans are specially installed to form a circulating air flow in the experimental cabin to ensure that the concentration of pollutants in the cabin is evenly distributed.

[0021] Step 2, according to Cu-TiO 2 Photocatalyst,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com