Catalyst and material for formaldehyde decomposition

A catalyst and formaldehyde technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as indoor formaldehyde that cannot be practically applied, and achieve stable degradation efficiency, Improve efficiency and increase durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

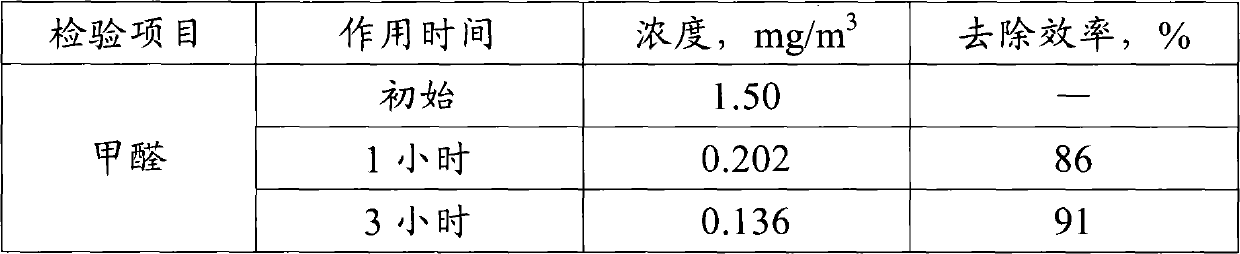

Examples

Embodiment 1

[0031] (1) To manganese dioxide powder with a purity of 75%, add manganese dioxide: alumina: silicon oxide: copper oxide: platinum oxide: magnesium oxide = 100:9:5:3:0.5:1 , mixing, and preparing a doped manganese dioxide catalyst. The melting points of manganese dioxide, aluminum oxide, silicon oxide, copper oxide, platinum oxide and magnesium oxide are 390°C, 2015°C, 1728°C, 1026°C, 450°C and 2852°C, respectively.

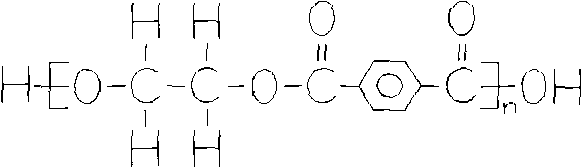

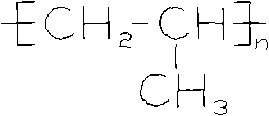

[0032] (2) By weight percentage, with 60% PET polyester fiber, 30% polypropylene fiber and 10% low-melting point fiber 4080 (Korean Sehan chemical fiber) to prepare a mixed material, in the mixing and carding process with 130g / m 2 The proportion of doped manganese dioxide catalyst prepared in advance was added.

[0033] (3) For the mixed material containing the doped manganese dioxide catalyst, the fluffy fiber web is reinforced into a nonwoven material by using the puncture effect of the needle.

[0034](4) The needle-punched non-woven mixed material is subjec...

Embodiment 2

[0037] (1) In the manganese dioxide powder with a purity of 87%, add and mix in the ratio of manganese dioxide: alumina: silicon oxide: copper oxide: platinum oxide: magnesium oxide = 100:11:5:5:1:2 , preparation of doped manganese dioxide catalyst.

[0038] (2) By weight percentage, with 45% PET polyester fiber, 30% polypropylene fiber and 25% low-melting point fiber 4080 (Korean Sehan Chemical Fiber) is formulated into mixed material, in mixing carding process, with 180g / m 2 The proportion of doped manganese dioxide catalyst prepared in advance was added.

[0039] (3) For the mixed material containing the doped manganese dioxide catalyst, the fluffy fiber web is reinforced into a nonwoven material by using the puncture effect of the needle.

[0040] (4) The needle-punched non-woven mixed material is subjected to heat roll treatment, and the treatment temperature and pressure are set at 124°C and 1550N / cm 2 . Finally, drying and finishing are carried out in order to obta...

Embodiment 3

[0043] (1) In the manganese dioxide powder with a purity of 95%, add and mix in the ratio of manganese dioxide: alumina: silicon oxide: copper oxide: platinum oxide: magnesium oxide = 100:14:7:6.5:1.5:2.4 , preparation of doped manganese dioxide catalyst.

[0044] (2) By weight percentage, with 40% PET polyester fiber, 27% polypropylene fiber and 33% low-melting point fiber 4080 (Korean Sehan) to prepare mixed material, in the mixing carding process with 210g / m 2 The proportion of doped manganese dioxide catalyst prepared in advance was added.

[0045] (3) For the mixed material containing the doped manganese dioxide catalyst, the fluffy fiber web is reinforced into a nonwoven material by using the puncture effect of the needle.

[0046] (4) The needle-punched non-woven mixed material is subjected to heat roll treatment, and the treatment temperature and pressure are set at 145°C and 1950N / cm 2 . Finally, drying and finishing are carried out in order to obtain a nonwoven ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Quality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com