Preparation method of environment-friendly interior wall top coating for preforming catalytic degradation on formaldehyde in air during photocatalysis and chemical oxidation

A technology of chemical oxidation and catalytic degradation, applied in the direction of coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of formaldehyde degradation agent

[0043] Dissolve 20g of titanium tetrachloride in 50ml of deionized water, and add ammonia water dropwise at 20°C to adjust the pH to 9-11. Settled at 20°C for 20 hours and filtered under reduced pressure. Wash the filter cake with deionized water until it does not contain chloride ions, dry it, and sieve it to obtain white titanium hydroxide powder ( ).

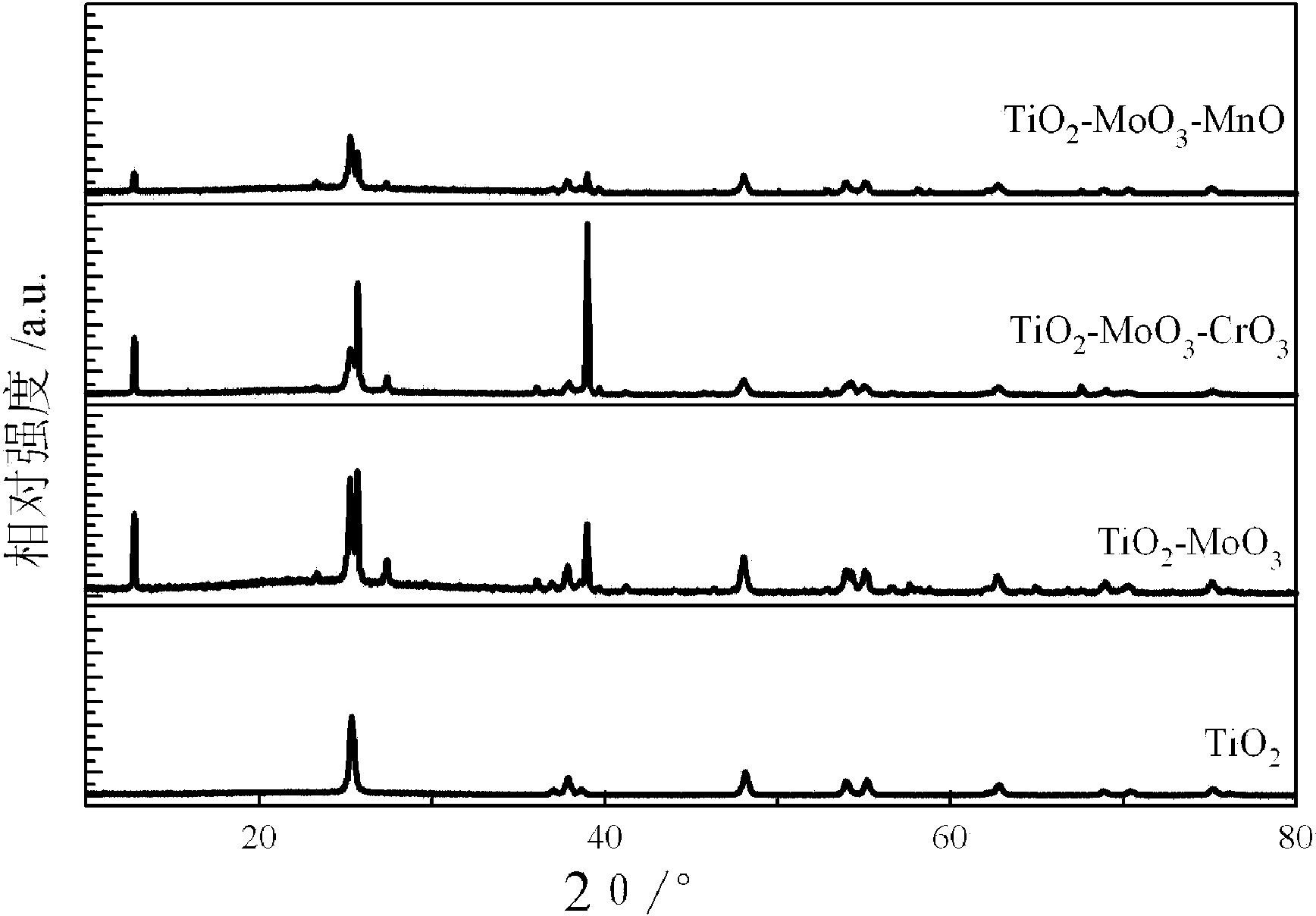

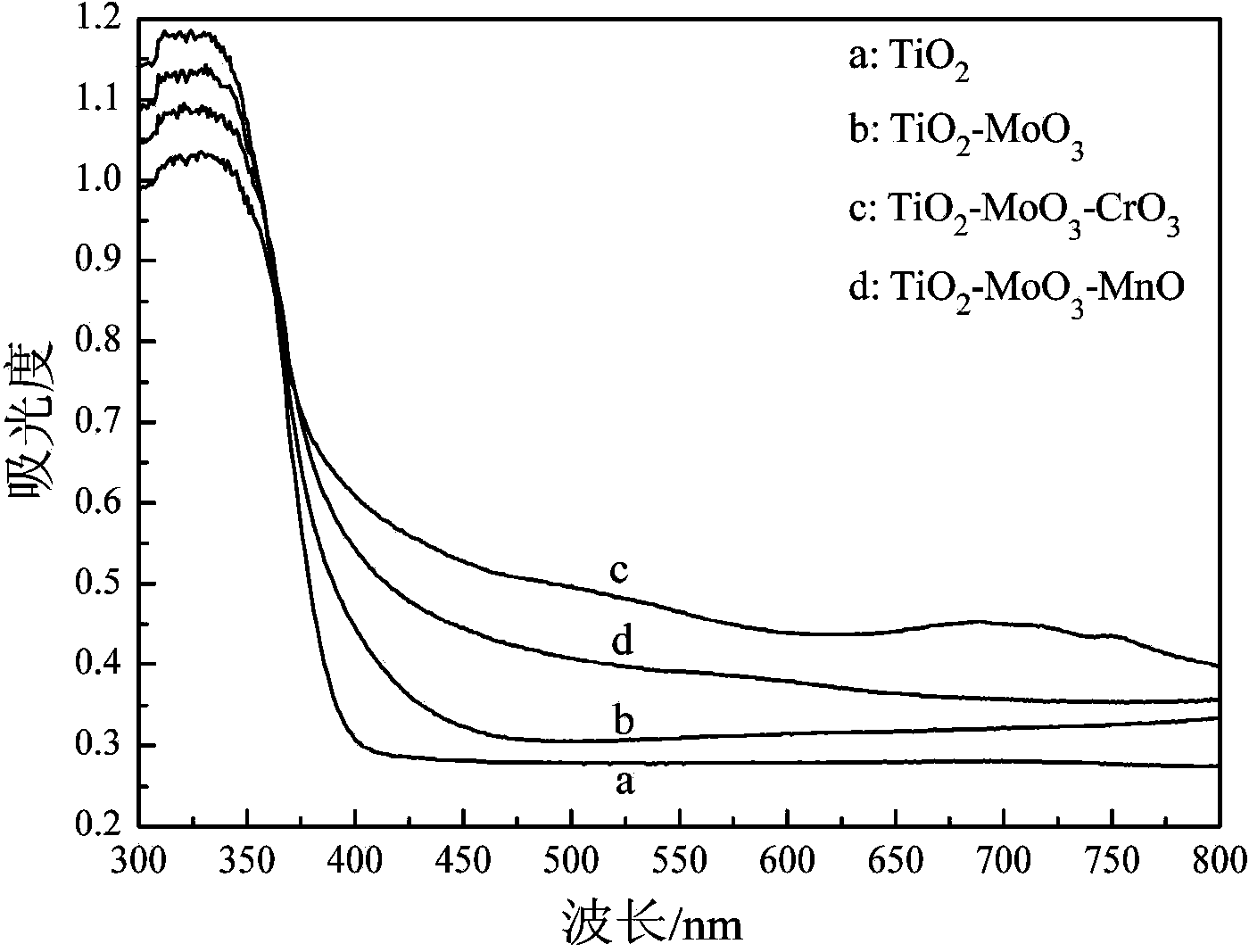

[0044]Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.4g of chromium trioxide, and stir for 4 hours. Heating and concentrating until the liquid disappears, and roasting in a box-type resistance furnace at 550°C for 3 hours to obtain a formaldehyde degradation agent. X-ray diffraction, ultraviolet diffuse reflectance, ammonia gas temperature-programmed adsorption-desorption and scanning electron microscopy were used for detection. The results are shown in figure 2 , 3 , 4 and 5.

[0045] (2) Modulatio...

Embodiment 2

[0053] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, then add 0.4g of manganese sulfate, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until the liquid disappears, and bake at 550°C for 3 hours to obtain a formaldehyde degradation agent. X-ray diffraction, ultraviolet diffuse reflectance and scanning electron microscopy are used for detection, the results are shown in figure 2 , 3 , 4 and 5.

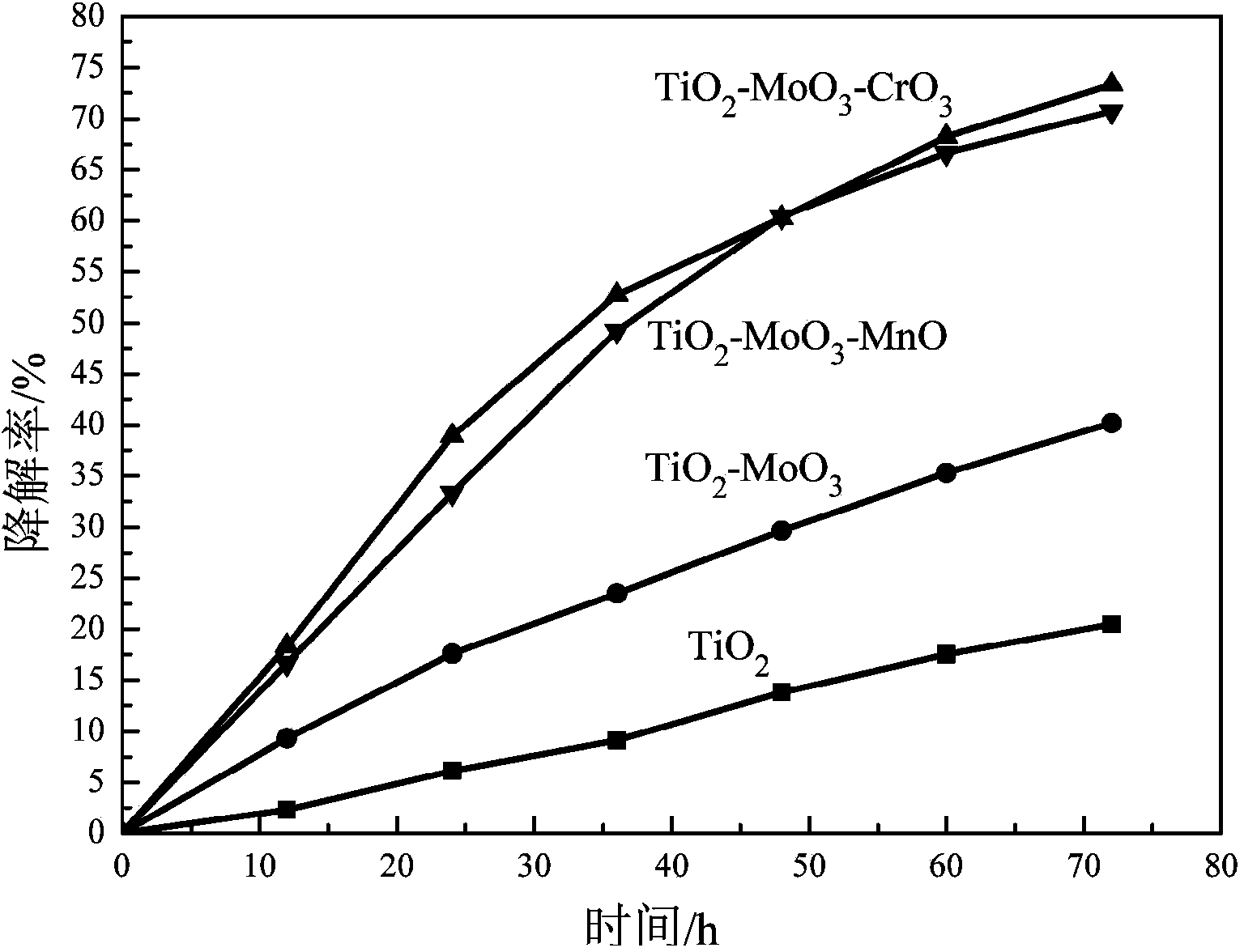

[0054] Make wall paint according to the method of embodiment 1, the effect of degrading formaldehyde sees figure 1 After 3 days, the degradation rate of formaldehyde was measured to be 70.7%.

Embodiment 3

[0056] Dissolve 4g of ammonium molybdate in 20ml (1mol / L) of sulfuric acid, add 10g of titanium hydroxide, and stir for 4 hours. Heat and concentrate in a box-type resistance furnace until the liquid disappears, and bake at 550°C for 3 hours to obtain a formaldehyde degradation agent. X-ray diffraction, ultraviolet diffuse reflectance and scanning electron microscopy are used for detection, the results are shown in figure 2 , 3 , 4 and 5.

[0057] Make wall paint according to the method of embodiment 1, the effect of degrading formaldehyde sees figure 1 After 3 days, the degradation rate of formaldehyde was measured to be 40.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com