Preparation method of iron doped carbon quantum dot/titanium dioxide composite photocatalyst and formaldehyde degradation method

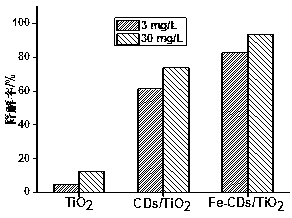

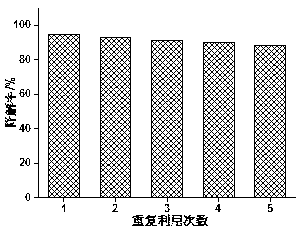

A technology of titanium dioxide and carbon quantum dots, applied in the chemical industry, can solve the problems of slow release and light utilization efficiency obstructing the photocatalytic effect, etc., and achieve the effects of easy separation, improved photocatalytic performance, and short degradation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Preparation of iron-doped carbon quantum dots: Weigh 10g of citric acid, 1g of ammonium ferrous sulfate dissolved in 50 mL of pure water, then add 5mL of ethylenediamine, ultrasonically mix for 10min, transfer to polytetrafluoroethylene The ethylene-lined reactor was heated at 200°C for 5 hours, and after natural cooling, it was centrifuged at 8000r / min for 15 minutes to remove large particles of impurities. After passing through a 0.22μm filter membrane, blue fluorescent iron-doped carbon quantum dots were obtained, and placed in a vacuum oven at 60°C Dry and set aside.

[0024] 2. Preparation of titanium dioxide: Weigh 2g of P25 titanium dioxide powder, disperse 0.2g of CTAB in 50mL of pure water, mechanically stir for 4 hours, place in a vacuum oven at 60°C for drying, and calcinate the dried powder at 400°C for 4 hours to eliminate titanium dioxide The negative charge aggregation effect on the surface results in calcined titanium dioxide.

[0025] 3. Preparation...

Embodiment 2

[0029] 1. Preparation of iron-doped carbon quantum dots: Weigh 15g of citric acid and 3g of ferrous ammonium sulfate in 100mL of pure water, then add 10mL of ethylenediamine, mix thoroughly by ultrasonication for 20min, and transfer to polytetrafluoroethylene The lined reactor was heated at 200°C for 7 hours, and after natural cooling, it was centrifuged at 8000r / min for 25 minutes to remove large particles of impurities. After passing through a 0.22μm filter membrane, blue fluorescent iron-doped carbon quantum dots were obtained, and dried in a vacuum oven at 60°C spare.

[0030] 2. Preparation of titanium dioxide: Weigh 4g of P25 titanium dioxide powder, 0.5g of CTAB dispersed in 50mL of pure water, mechanically stir for 6 hours, then place in a vacuum oven at 60°C for drying, and calcinate the dried powder at 400°C for 6 hours to eliminate titanium dioxide The negative charge aggregation effect on the surface results in calcined titanium dioxide.

[0031] 3. Preparation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com