Catalyst used for degrading formaldehyde wastewater, preparation method and application thereof

A formaldehyde wastewater and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, heterogeneous catalyst chemical elements, etc., can solve the problems of unstable carrier structure, insufficient active sites, low specific surface area, etc., and achieve change Electron cloud density, solution to recycling, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

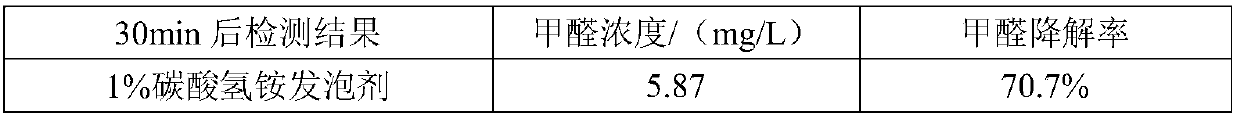

[0022] Wherein, the preparation method of novel porous manganese dioxide carrier HMO comprises the steps: potassium permanganate solution is added dropwise to polyethylene glycol (PEG), / methyl cellulose (MC) / hydroxypropyl methyl cellulose ( HPMC), diluted octanol / isononanol solution, manganese sulfate solution, the mixed solution was ultrasonicated for 10min, then stirred for 1h, and then the uniformly mixed solution was added dropwise to polymethyl methacrylate (PMMA) / ultrasonic Fine spherical aluminum powder, ammonium bicarbonate / sodium bicarbonate, mixed solution, slowly stirred to form a uniform dispersion, placed under high temperature and high pressure conditions to form a gel, suction filtered, washed, dried under vacuum conditions, and used Ground in an agate mortar and roasted to obtain a brown-black HMO carrier. Control the weight ratio of manganese sulfate and potassium permanganate to be 1:0.5-2.

[0023] The preparation process of M / HMO catalyst comprises: get co...

Embodiment 1

[0025] Performance comparison of embodiment 1 novel HMO carrier and porous manganese dioxide carrier

[0026] Using iron oxide as the catalyst active center and HMO or porous manganese dioxide as the catalyst support, Fe 2 o 3 / HMO catalyst and Fe 2 o 3 / MnO 2 catalyst.

[0027] Fe 2 o 3 The preparation process of HMO / HMO catalyst is as follows: potassium permanganate solution is added dropwise in polyethylene glycol (PEG), diluted octanol, manganese sulfate solution, ultrasonic, so that the weight ratio of manganese sulfate and potassium permanganate is 1 : 1, stir, then add the uniformly mixed solution dropwise to the mixed solution containing polymethyl methacrylate (PMMA), ammonium bicarbonate, slowly stir to form a uniform dispersion, high temperature and high pressure, form a gel, pump Filter, wash, dry under vacuum, grind with agate mortar, and roast to obtain brown-black HMO carrier. Control the ratio of the weight of the metal salt in the active component prec...

Embodiment 2

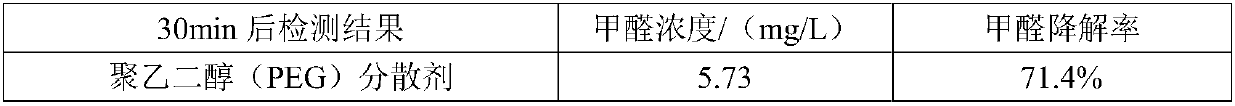

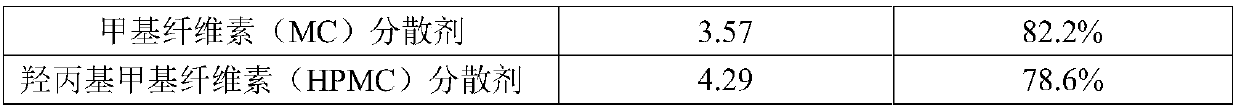

[0033] The performance comparison of embodiment 2 three kinds of dispersants

[0034] Add potassium permanganate solution dropwise to polyethylene glycol (PEG) / methylcellulose (MC) / hydroxypropylmethylcellulose (HPMC), diluted octanol solution, manganese sulfate solution, and ultrasonically The weight ratio of manganese sulfate and potassium permanganate is 1:1, stir, and then add the uniformly mixed solution dropwise to the mixed solution containing polymethyl methacrylate (PMMA) and ammonium bicarbonate, stir slowly to form a uniform The dispersion liquid was formed into a gel under high temperature and high pressure, filtered, washed, dried under vacuum, ground with an agate mortar, and roasted to obtain a brown-black HMO carrier. Control the massfraction of polyethylene glycol (PEG) / methylcellulose (MC) / hydroxypropylmethylcellulose (HPMC) to be 0.1%, the weight that contains metal salt and the weight of HMO carrier in the active component precursor solution The ratio is 5:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com