Palladium-based catalyst for thermocatalytic formaldehyde degradation

A formaldehyde degradation and catalyst technology, which is applied in the field of thermal catalytic materials and environmental protection, can solve the problems of high temperature calcination, limitation, and high catalyst manufacturing cost, and achieves the effects of mild preparation conditions, improved capacity, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

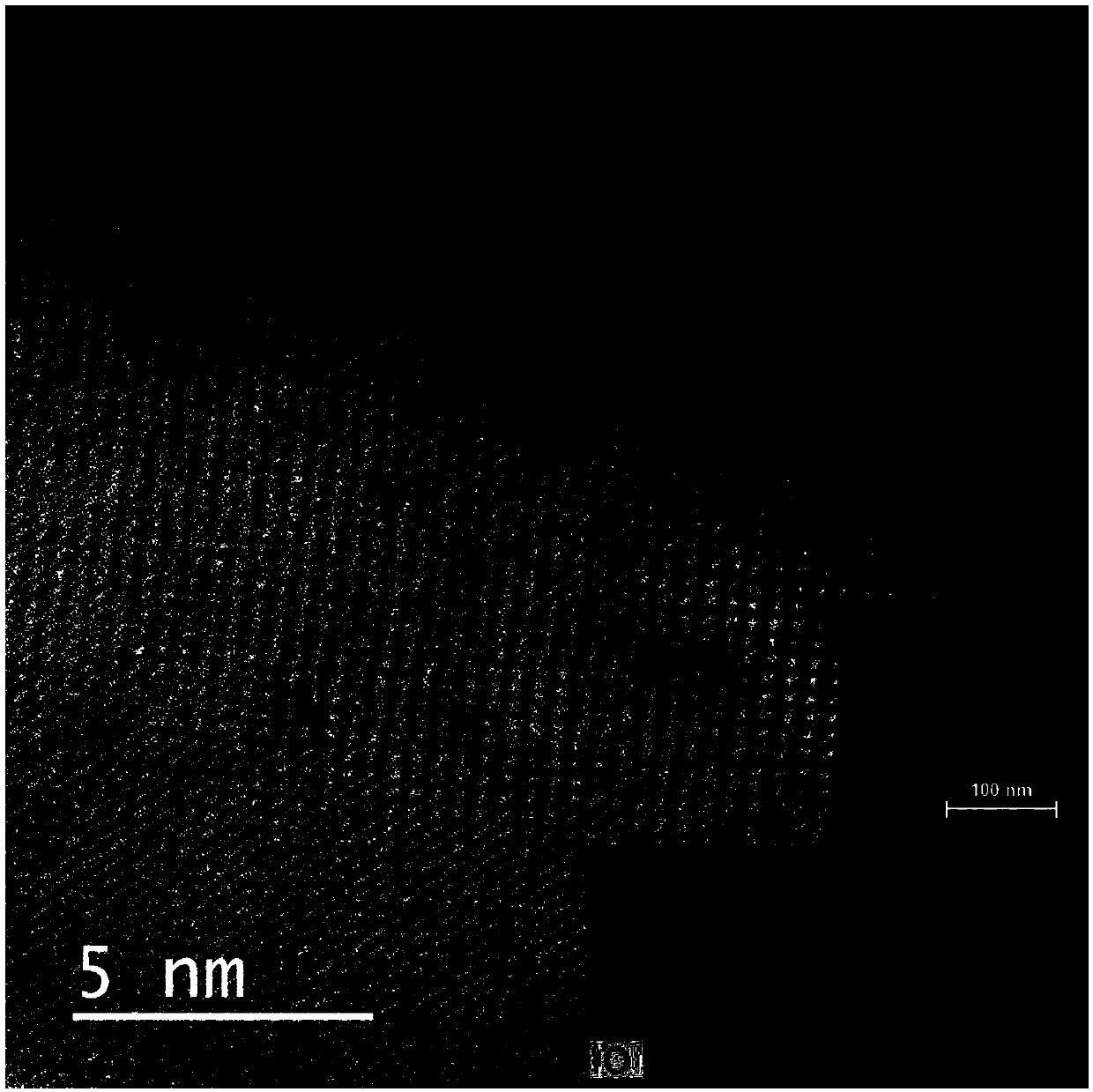

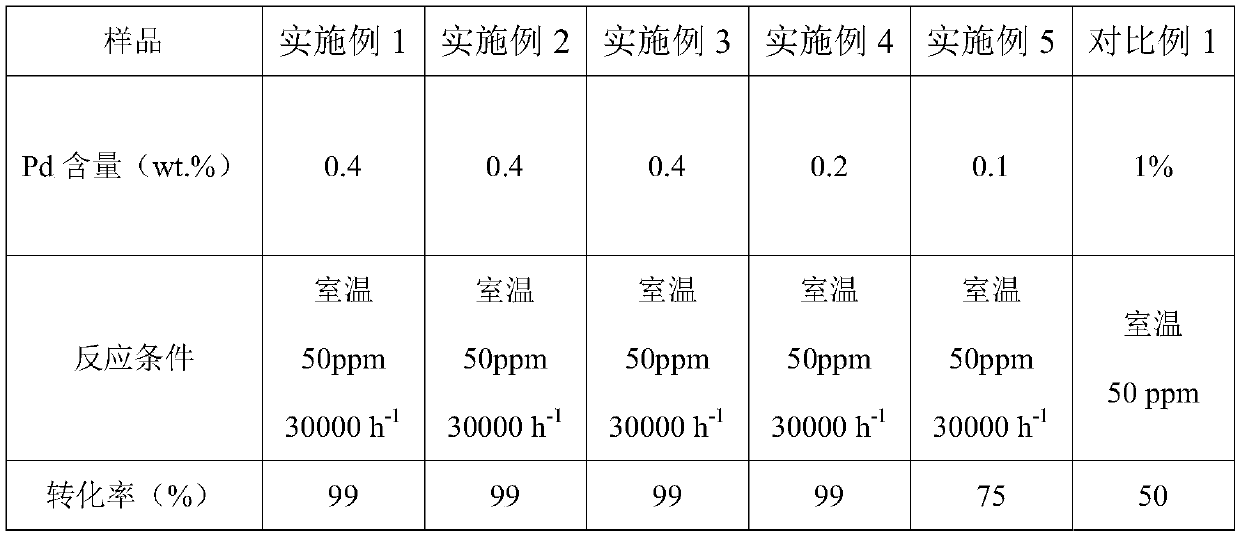

Embodiment 1

[0027] A preparation method of palladium-based catalyst for thermal catalytic degradation of formaldehyde: (1) Take 0.5 g of TiO 2 Placed in a fixed bed reduction reaction tube; (2) At room temperature at a heating rate of 10°C / min, the temperature is increased to 300°C, and hydrogen reduction is carried out at different temperatures for 3 hours, and then hydrogen gas is continued to cool to room temperature naturally; (3) Absorption Add 0.4ml of 10mg / ml palladium nitrate solution into a three-necked flask, then add pure water, and continue to stir; (4) Under stirring, add reduced anatase (TiO 2 ) Solid, stir and react for 1h; (5) Then add 1mol / L NaOH solution dropwise until the pH of the solution is 10; (6) Weigh 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 The solution was added dropwise to the aforementioned solution, and the reaction was continued for 2 hours under stirring; (7) After the reaction was completed, the solution was centrifuged at 8000 rpm for 5 min...

Embodiment 2

[0029] A preparation method of palladium-based catalyst for thermal catalytic degradation of formaldehyde: (1) Take 0.5 g of TiO 2 Placed in a fixed-bed reduction reaction tube; (2) At room temperature at a heating rate of 10°C / min, raise to 400°C, and perform hydrogen reduction at different temperatures for 3 hours, and then continue to pass hydrogen to cool to room temperature naturally; (3) Absorb Add 0.4ml of 10mg / ml palladium nitrate solution into a three-necked flask, then add pure water, and continue to stir; (4) Under stirring, add reduced anatase (TiO 2 ) Solid, stir and react for 1h; (5) Then add 1mol / L NaOH solution dropwise until the pH of the solution is 10; (6) Weigh 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 The solution was added dropwise to the aforementioned solution, and the reaction was continued for 2 hours under stirring; (7) After the reaction was completed, the solution was centrifuged at 8000 rpm for 5 minutes and washed with deionized wat...

Embodiment 3

[0031] A preparation method of palladium-based catalyst for thermal catalytic degradation of formaldehyde: (1) Take 0.5 g of TiO 2 Placed in a fixed-bed reduction reaction tube; (2) At room temperature at a heating rate of 10°C / min, increase to 500°C, and perform hydrogen reduction at different temperatures for 3 hours, and then continue to pass hydrogen to cool to room temperature naturally; (3) Absorb Add 0.2ml of 10mg / ml palladium nitrate solution into the three-necked flask, then add pure water, and continue to stir; (4) Under stirring, add the reduced anatase (TiO 2 ) Solid, stir and react for 1h; (5) Then add 1mol / L NaOH solution dropwise until the pH of the solution is 10; (6) Weigh 0.0071g NaBH 4 Solid, add 10ml pure water to prepare NaBH 4 The solution was added dropwise to the aforementioned solution, and the reaction was continued for 2 hours under stirring; (7) After the reaction was completed, the solution was centrifuged at 8000 rpm for 5 minutes and washed with deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com