Mixed crystal TiO2/g-C3N4 nano hollow tube composite material and preparation method thereof

A composite material, g-c3n4 technology, applied in the field of preparation of high-efficiency photocatalysts, can solve the problems of difficult preparation of high specific surface, complicated preparation process, difficult to control the shape, etc., to achieve low cost, simple preparation process, good light The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

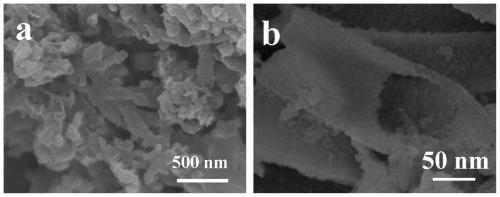

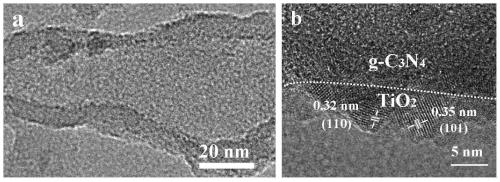

[0014] (1) Weigh 10 g of urea, put it into a crucible with a lid, raise the temperature to 550° C. at a heating rate of 5° C. / min, and keep it warm for 4 hours. After cooling to room temperature, the product was collected. After grinding, heat up to 500°C at a heating rate of 5°C / min, keep it warm for 4 hours, and cool to room temperature to obtain g-C 3 N 4 nanotubes.

[0015] (2) Weigh 80 mg of g-C prepared in step (1) 3 N 4 The hollow nanotubes were ultrasonically dispersed in deionized water, and 0.02ml of TiCl was added 4 , stir evenly;

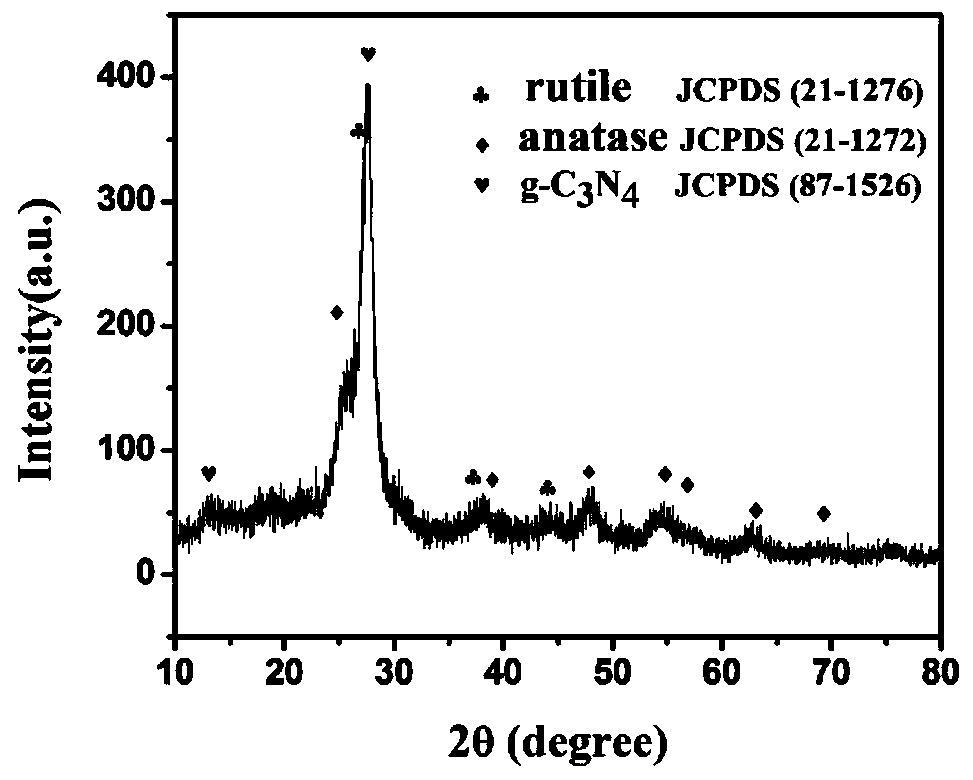

[0016] (3) Weigh 0.028g of hexamethylenetetramine and dissolve it in deionized water, pour the hexamethylenetetramine solution into the mixture obtained in step (2), after stirring evenly, transfer the mixture to the autoclave Put it in an oven at 180°C for 1 h, take it out, and after cooling, wash the product three times with distilled water and ethanol, and dry at 60°C to obtain rutile and anatase mixed crystal TiO 2 / g -C 3 N ...

Embodiment 2

[0018] (1) Weigh 10 g of urea, put it into a crucible with a lid, raise the temperature to 550° C. at a heating rate of 5° C. / min, and keep it warm for 4 hours. After cooling to room temperature, the product was collected. After grinding, heat up to 500°C at a heating rate of 5°C / min, keep it warm for 4 hours, and cool to room temperature to obtain g-C 3 N 4 nanotubes.

[0019] (2) Weigh 80 mg of g-C prepared in step (1) 3 N 4 The hollow nanotubes were ultrasonically dispersed in deionized water, and 0.01ml of TiCl was added 4 , stir evenly;

[0020] (3) Weigh 0.014g of hexamethylenetetramine and dissolve it in deionized water, pour the hexamethylenetetramine solution into the mixture obtained in step (2), after stirring evenly, transfer the mixture to the autoclave Put it in an oven at 180°C for 1 h, take it out, and after cooling, wash the product three times with distilled water and ethanol, and dry at 60°C to obtain rutile and anatase mixed crystal TiO 2 / g -C 3 N ...

Embodiment 3

[0022] (1) Weigh 10 g of urea, put it into a crucible with a lid, raise the temperature to 550° C. at a heating rate of 5° C. / min, and keep it warm for 4 hours. After cooling to room temperature, the product was collected. After grinding, heat up to 500°C at a heating rate of 5°C / min, keep it warm for 4 hours, and cool to room temperature to obtain g-C 3 N4 nanotubes.

[0023] (2) Weigh 80 mg of g-C prepared in step (1) 3 N 4 The hollow nanotubes were ultrasonically dispersed in deionized water, and 0.03ml of TiCl was added 4 , stir evenly;

[0024] (3) Weigh 0.042g of hexamethylenetetramine and dissolve it in deionized water, pour the hexamethylenetetramine solution into the mixture obtained in step (2), after stirring evenly, transfer the mixture to the autoclave Put it in an oven at 180°C for 1 h, take it out, and after cooling, wash the product three times with distilled water and ethanol, and dry at 60°C to obtain rutile and anatase mixed crystal TiO 2 / g -C 3 N 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com