Pressing plate structure fixed on clamping groove and use method thereof

A technology of clamping groove and pressing plate, applied in the field of pressing plate structure, can solve the problems of inaccurate pressing and positioning, complex structure, etc., and achieve the effect of simple structure, simple principle and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

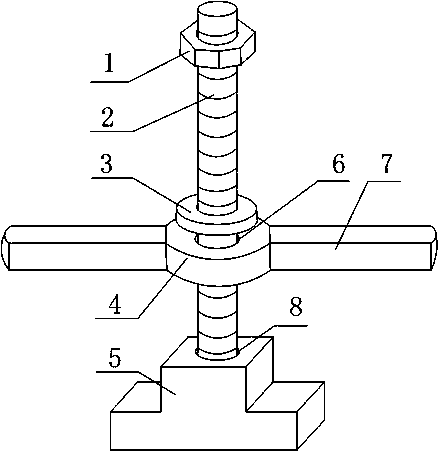

[0016] Such as figure 1 As shown, the structure of the pressing plate fixed on the card slot includes a fixed block 5, and the fixed block 5 is provided with a threaded through hole 8, and the threaded through hole 8 is internally screwed with a screw rod 2, and the outer wall of the screw rod 2 is fitted There is a nut 1, a positioning device is arranged between the nut 1 and the fixing block 5, a through hole 6 is arranged on the positioning device, and the screw rod 2 passes through the inside of the through hole 6. Through the screw thread on the screw rod 2, the operator can screw the nut 1 to fix the positioning device, and adjust according to the length of the workpiece, so that workpieces of different sizes can be fixed, and the fixing effect is good.

[0017] A washer 3 is arranged between the nut 1 and the positioning device, and the washer 3 fits on the outer wall of the screw rod 2 . The washer 3 is used as a buffer component between the nut 1 and the positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com