Movable twin-tub cloth bag dust-collection device

A dust suction device, mobile technology, applied in bark area/debris/dust/waste removal, wood processing equipment, manufacturing tools, etc., can solve the hazards of production equipment and operators, physical damage of operators, production equipment Equipment jamming and other problems, to achieve good dust collection effect, simple principle, and reduce maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

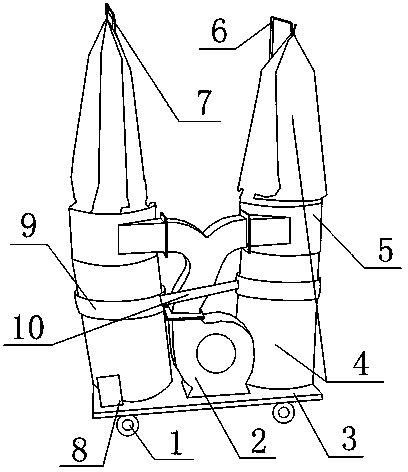

[0013] like figure 1 As shown, the mobile double-barrel bag vacuum device includes a support plate 3 on which a container and a vacuum cleaner 2 are arranged, the container is connected to the vacuum cleaner 2, and the bottom of the support plate Several rollers 1 are arranged at the end, and a support clip is arranged between the rollers 1 and the support plate 3 . The dust collection system has a certain weight after vacuuming, and the dust collection system is moved quickly by the roller 1 . And utilize roller 1, can realize the timeliness of vacuuming, have reduced the labor intensity of operator's handling, and support clip supports the rotation of roller 1 on support plate 3.

[0014] The number of the containers is two, the vacuum cleaner 2 is arranged between the two containers, and the vacuum cleaner 2 is connected with the two containers at the same time, and the outer walls of the containers are fitted with hoops 9 , A connecting plate 10 is arranged between the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com