Petroleum component lifting equipment adopting hydraulic pressure as power

A power and oil technology, applied in the field of oil component lifting equipment, can solve the problems of small floor space, high use cost, large floor space, etc., and achieve the effect of small floor space, low cost, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

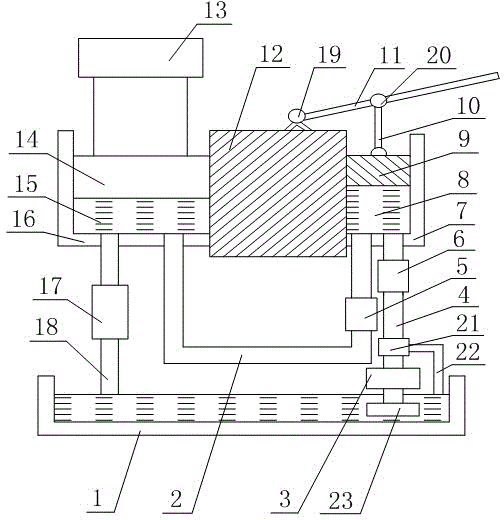

[0013] Such as figure 1 As shown, a petroleum component lifting equipment using hydraulic pressure as power includes an oil tank 1 in which a filter device 23 is provided, a hydraulic pump 3 is provided above the oil tank 1, and the hydraulic pump 3 is connected to the filter device 23, and the hydraulic pump 3 A large hydraulic cylinder 16 and a small hydraulic cylinder 7 communicating with each other are provided above. Both the large hydraulic cylinder 16 and the small hydraulic cylinder 7 are connected to the oil tank 1, the small hydraulic cylinder 7 is connected to the hydraulic pump 3, and the large hydraulic cylinder 16 and the small hydraulic cylinder The top of 7 is provided with an opening, a positioning block 12 is provided between the large hydraulic cylinder 16 and the small hydraulic cylinder 7, and the positioning block 12 is fixed to the large hydraulic cylinder 16 and the small hydraulic cylinder 7 at the same time, and the large hydraulic cylinder 16 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com