Loader constant and variable hydraulic system based on flow amplifying steering

A flow amplification, hydraulic system technology, applied in the field of hydraulic system and loader hydraulic system, can solve the problem of uncontrollable opening and closing speed of the unloading valve block, the fixed variable system cannot meet the use requirements, and the vibration and noise of the whole machine can be stimulated. problems, to achieve the effect of improving energy saving effect and micro-controllability, optimizing principle and structure, and eliminating energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

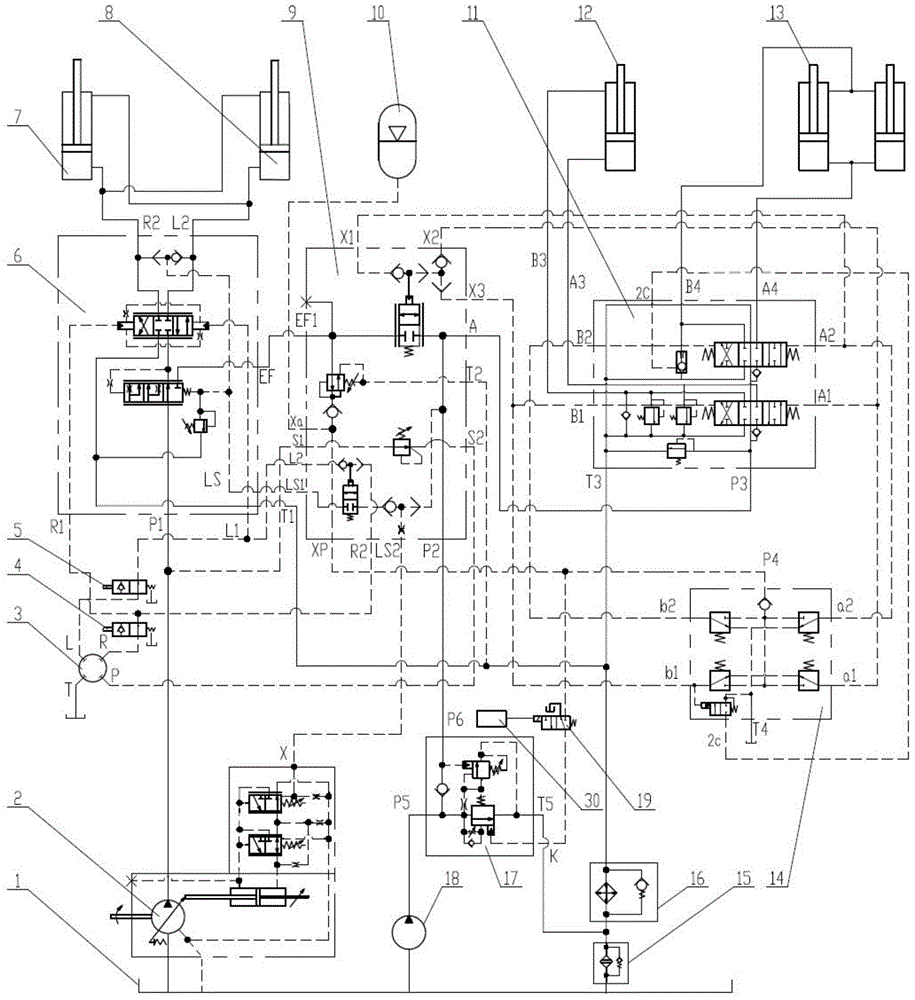

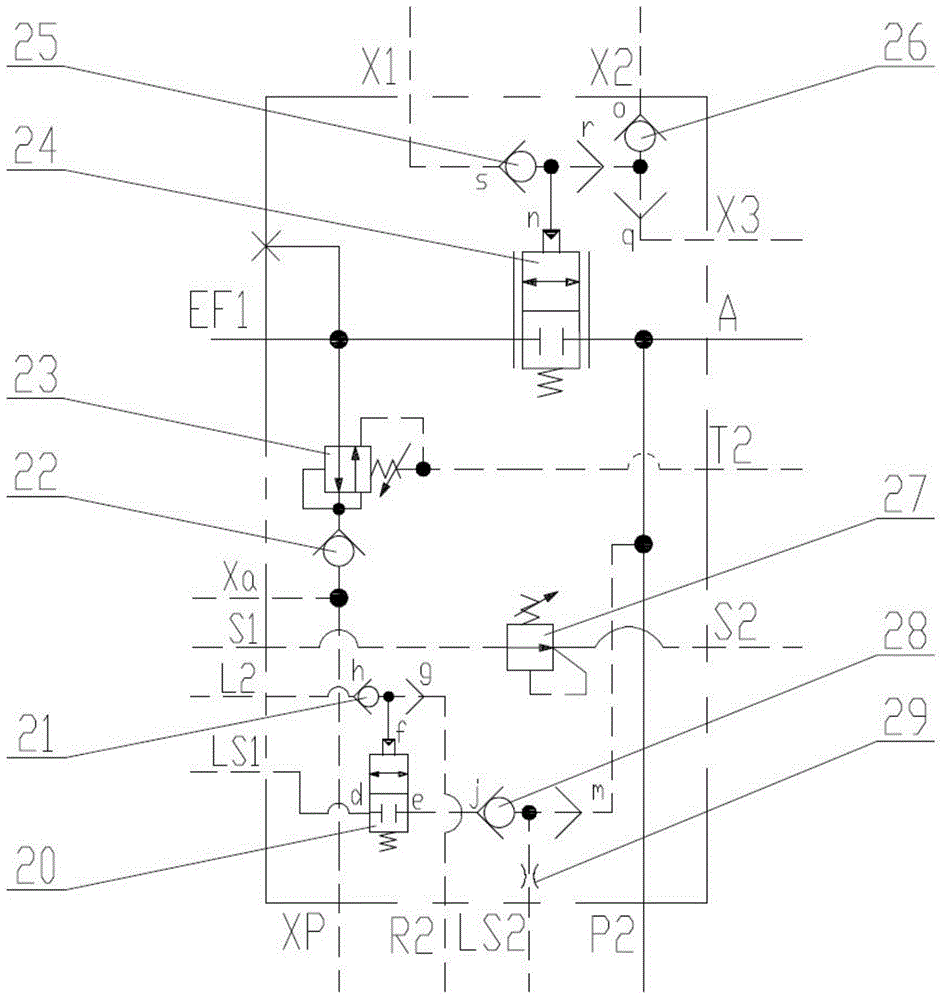

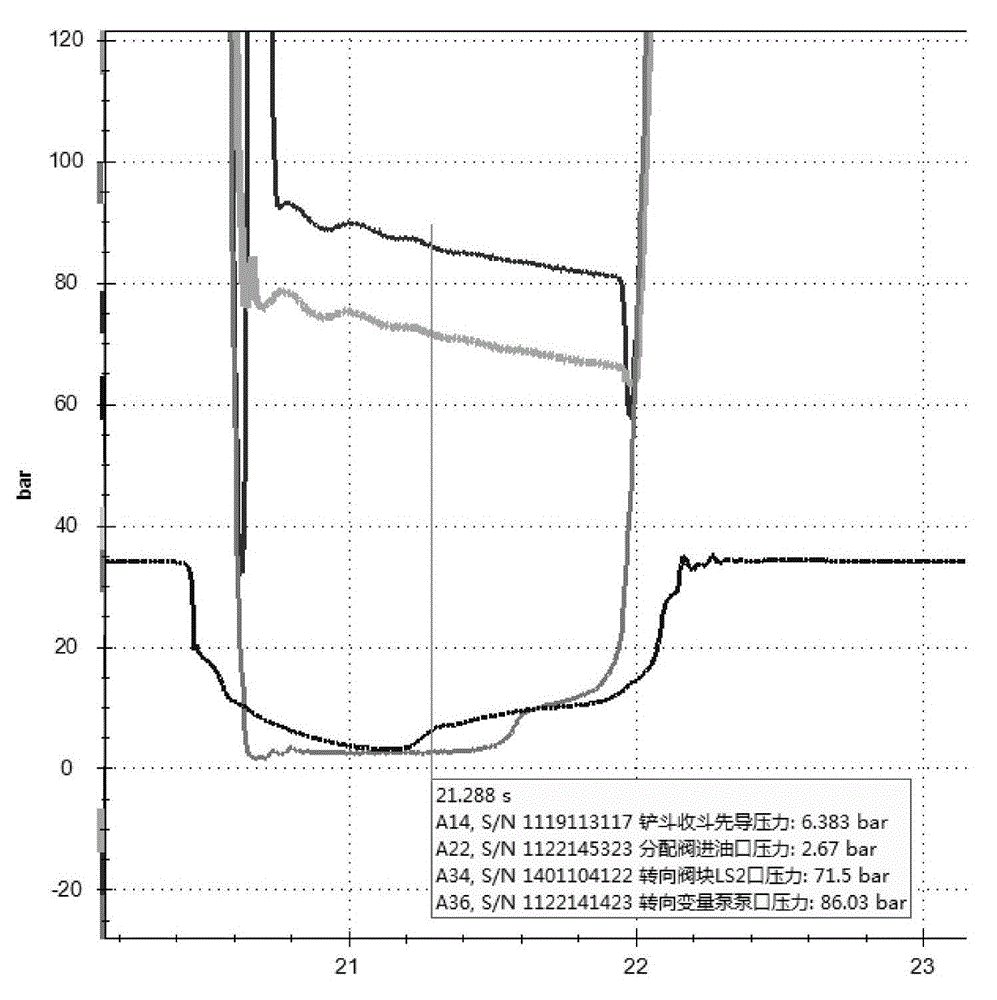

[0020] Such as figure 1As shown, a loader fixed variable hydraulic system based on flow amplification steering, including hydraulic oil tank 1, variable pump 2, steering gear 3, right limit valve 4, left limit valve 5, flow amplification valve 6, left steering cylinder 7. Right steering cylinder 8, flow control valve block 9, accumulator 10, distribution valve 11, dump cylinder 12, boom cylinder 13, pilot valve 14, unloading valve block 17, quantitative pump 18, working mode switching solenoid valve 19 and working mode switching switch 30, the oil suction port of the variable pump 2 is connected with the hydraulic oil tank 1, the oil outlet port of the variable pump 2 is connected with the P1 port of the flow amplifying valve 6, and the S1 port of the flow control valve block 9, and the flow amplifying valve 6 The R2 port of the valve is connected with the rodless chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com