Preparation method for polypyrrole and graphene oxide based sponge structural material

A structural material, graphene technology, applied in the fields of conductive materials and water-absorbing materials, can solve problems such as limiting the application of graphene, and achieve the effects of low production cost, good application prospects, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1) prepare graphene oxide according to the method reported in literature (Adv.Funct.Mater.2009,19,2297-2302);

[0020] 2) adding graphene oxide, direct red 31 and pyrrole monomer into deionized water respectively to obtain solution A, the mass percent concentration of graphene oxide in solution A is 0.2wt%, and the concentration of direct red 31 is 0.05mol / L, The concentration of pyrrole monomer is 0.05mol / L;

[0021] 3) Add 20 mL of 0.1 mol / L ferric chloride solution to 10 mL of solution A, stir for 2 minutes, and then stand at 0°C for 24 hours;

[0022] 4) Filter the generated precipitate, wash with methanol, dilute hydrochloric acid, and distilled water three times each, and then vacuum-dry at room temperature for 24 hours to obtain a sponge structure material based on polypyrrole and graphene oxide.

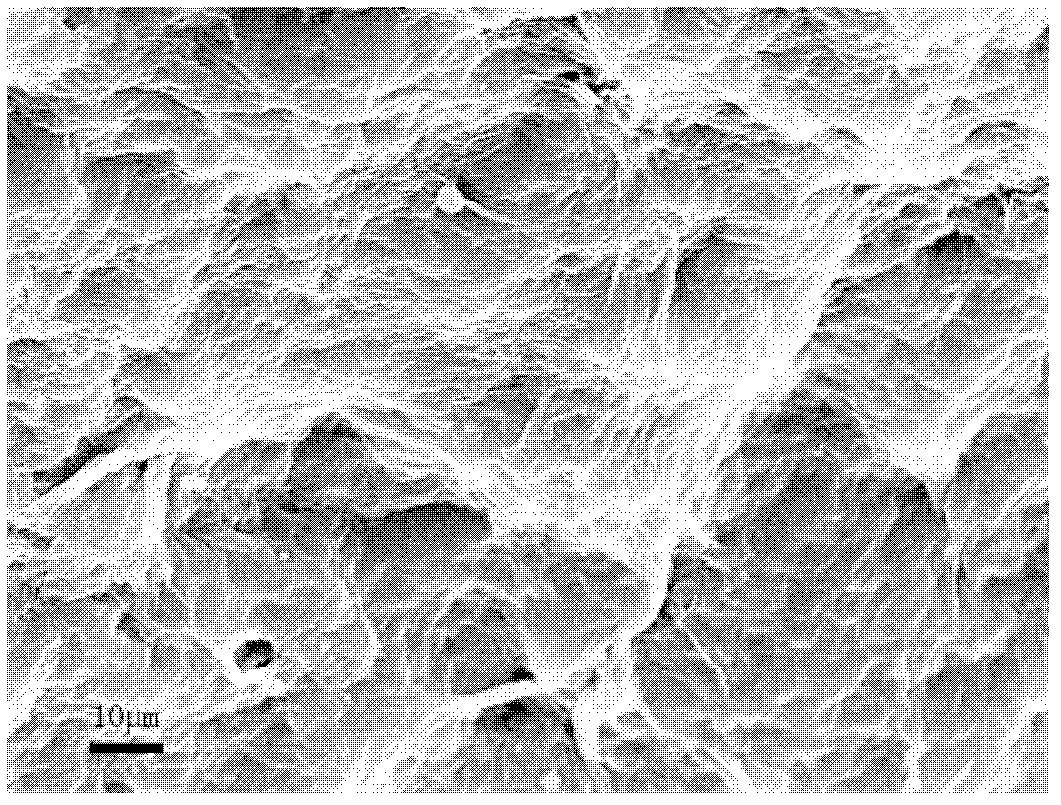

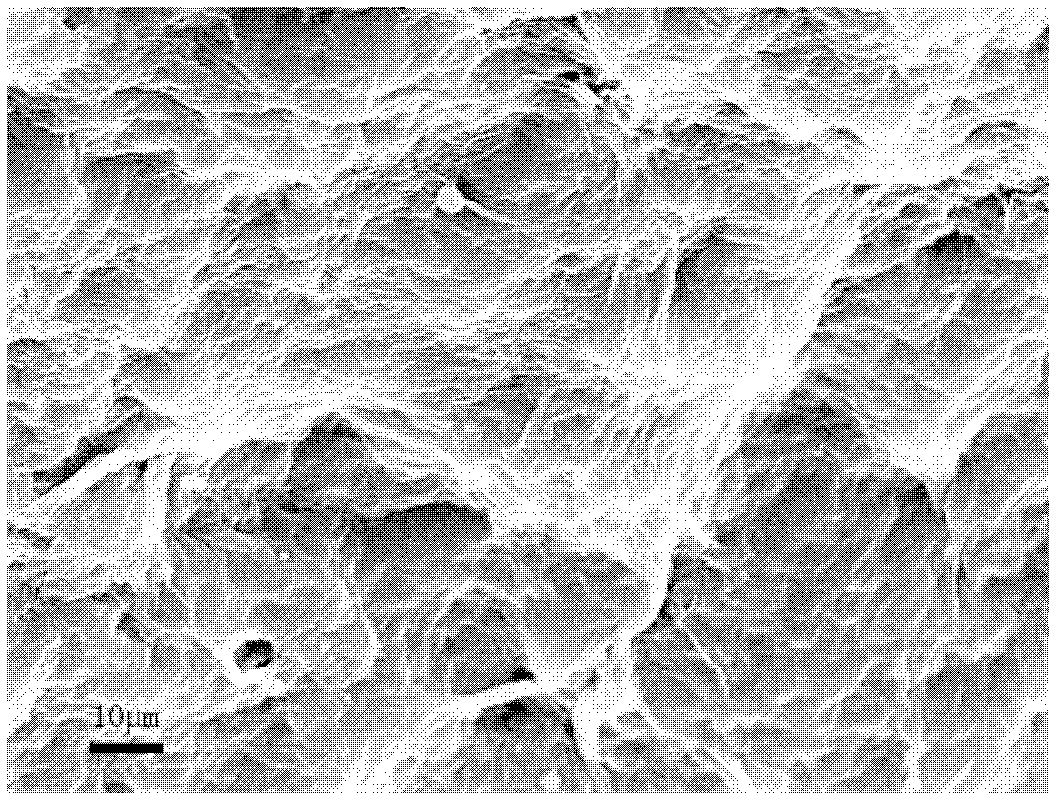

[0023] The sponge structure material (product) based on polypyrrole and graphene oxide is as soft as a sponge when pinched in the hand. figure 1 It is the scanning e...

Embodiment 2

[0025] 1) with step 1) among the embodiment 1;

[0026] 2) Graphene oxide, methyl orange and pyrrole monomer were added into deionized water respectively to obtain solution A, the mass percentage concentration of graphene oxide in solution A was 0.3wt%, and the concentration of methyl orange was 0.1mol / L, The concentration of pyrrole monomer is 0.08mol / L;

[0027] 3) Add 15 mL of 0.2 mol / L ferric nitrate solution to 15 mL of solution A, stir for 3 minutes, and then stand at 10°C for 30 hours;

[0028] 4) Filter the generated precipitate, wash with methanol, dilute acetic acid, and distilled water three times each, and then vacuum-dry at room temperature for 24 hours to obtain a sponge structure material based on polypyrrole and graphene oxide.

Embodiment 3

[0030] 1) with step 1) among the embodiment 1;

[0031] 2) adding graphene oxide, acid scarlet G and pyrrole monomer into deionized water respectively to obtain solution A, the mass percentage concentration of graphene oxide in solution A is 0.5wt%, and the concentration of acid scarlet G is 0.15mol / L, The concentration of pyrrole monomer is 0.1mol / L;

[0032] 3) Add 30mL of 0.1mol / L ferric sulfate solution to 20mL of solution A, stir for 4 minutes, and then stand at 20°C for 24 hours;

[0033] 4) Filter the generated precipitate, wash with methanol, dilute sulfuric acid, and distilled water three times each, and then vacuum-dry at room temperature for 24 hours to obtain a sponge structure material based on polypyrrole and graphene oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com