Method for manufacturing high-reliability heterogeneous heat-dissipating cold plate

A heat-dissipating cold plate, reliable technology, applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, etc., can solve problems such as insufficient reliability of work, limited layout design, differences in heat dissipation cold plate, etc., to achieve outstanding heat conduction Capability, low manufacturing cost, and improved failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

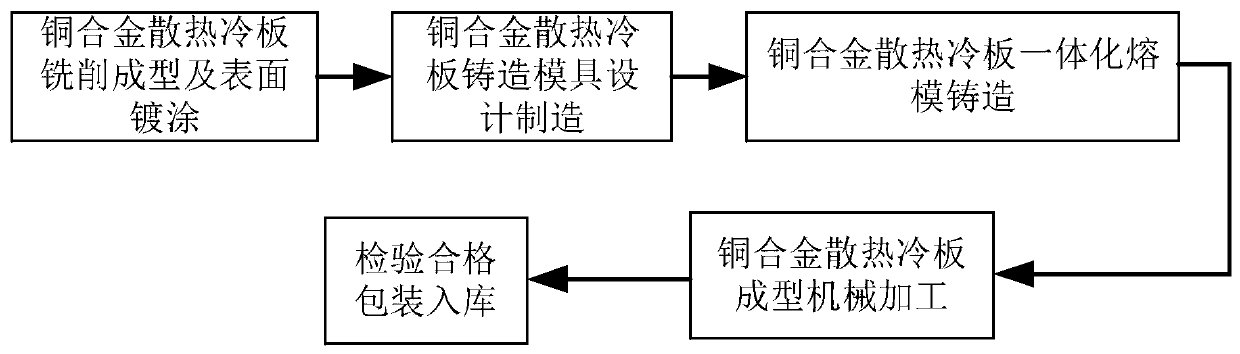

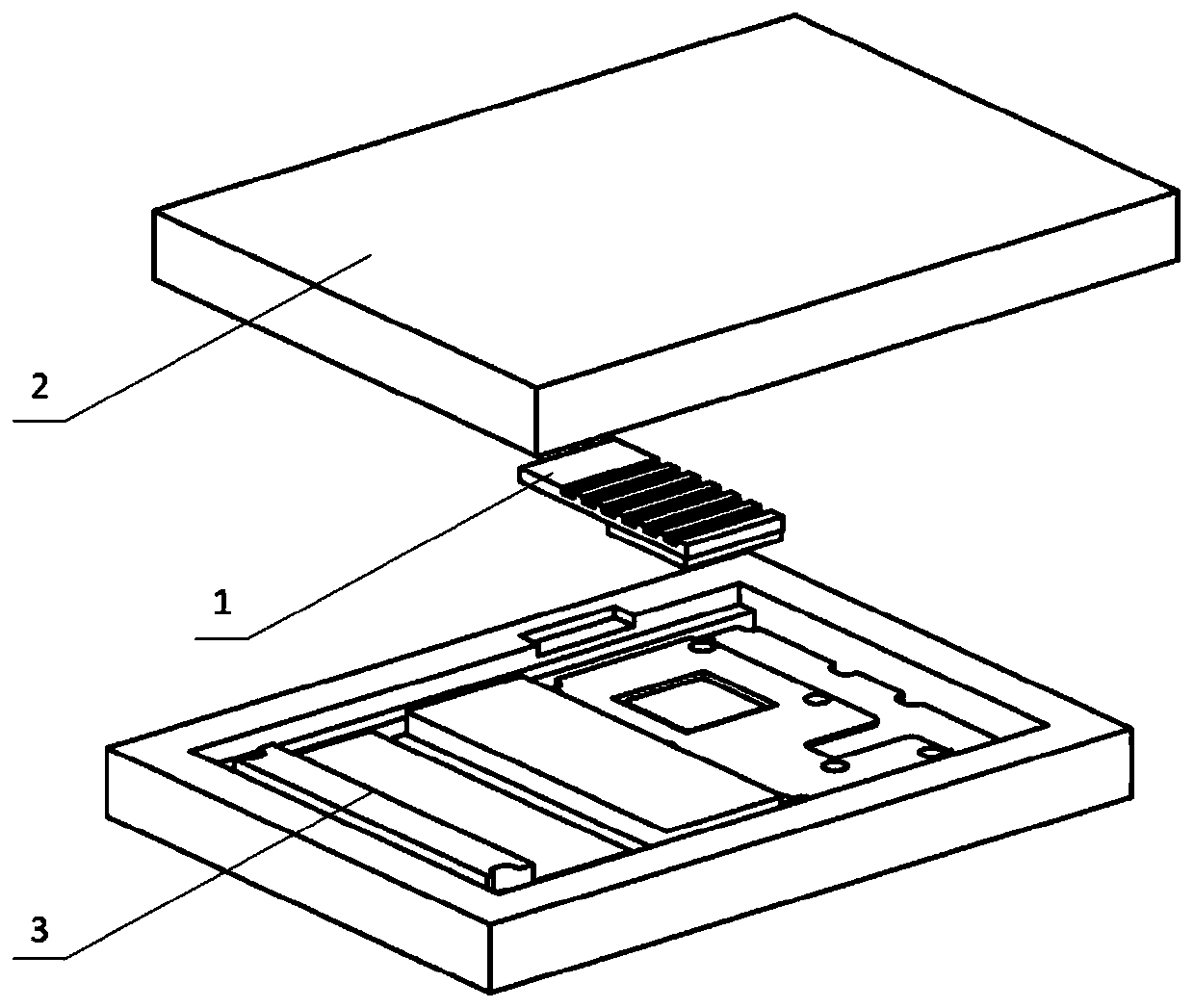

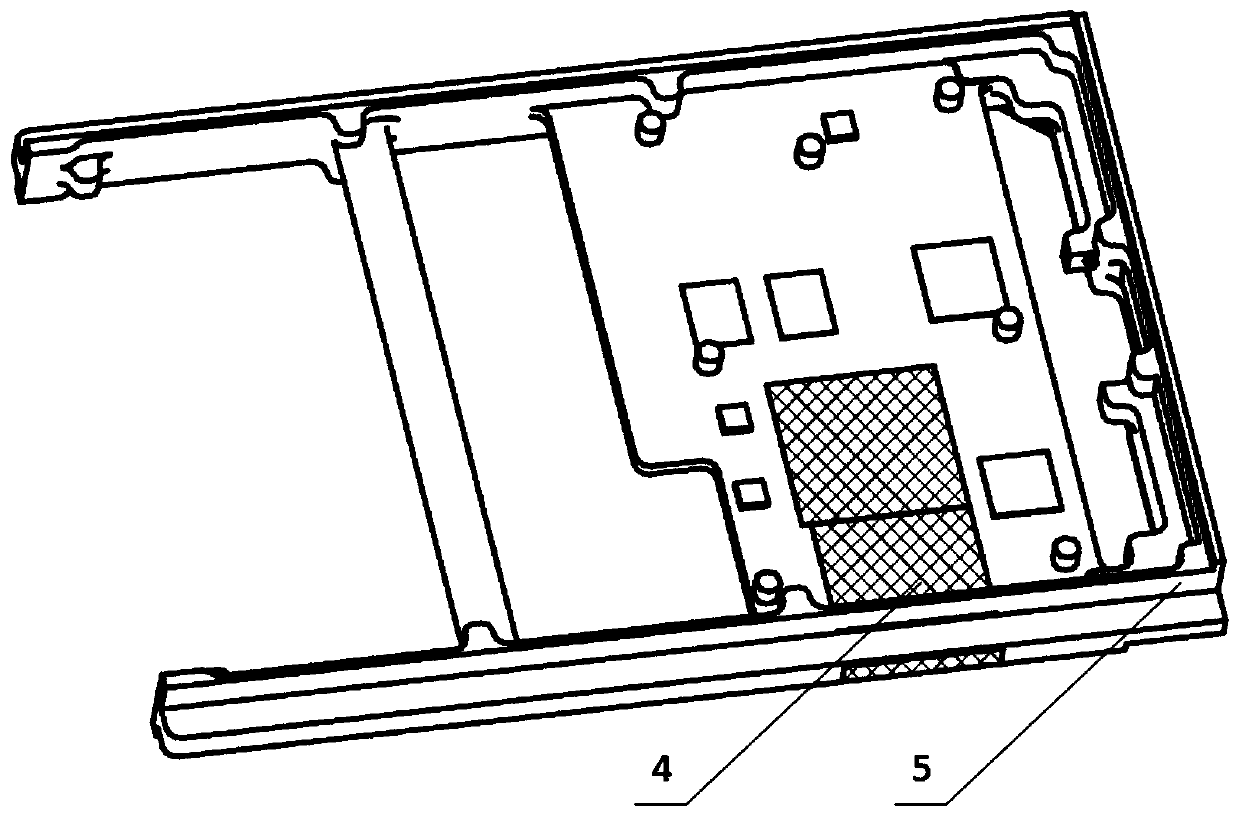

[0016] refer to Figure 1-Figure 3 . According to the present invention, according to the design requirements of the heat dissipation channel, the position of the heat dissipation cold plate corresponding to the high heat components is laid out, and the conduction and heat dissipation path of the horizontal bar tooth that increases the contact area with the box body is made on the copper alloy insert (1). The rack gear extends to the position where the box body (5) is installed with ribs; and the surface of the copper alloy insert (1) is sprayed with a nickel alloy coating with high heat insulation as a surface protection layer to isolate direct contact with the cast aluminum during casting Then the copper alloy insert (1) is embedded in the wax mold on the right side of the upper cavity (2) of the casting mold and the lower cavity (3) of the casting mold, and the mold making and making Shell and roasting process, integrated investment molding casting of copper alloy insert (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com