Infrared detector structure based on micro-bridge resonator and manufacturing method

A technology of infrared detectors and resonators, which is applied in the direction of electric radiation detectors, radiation pyrometry, instruments, etc., can solve the problems of difficult to increase the dielectric temperature coefficient value of pyroelectric thin films, the decrease of ferroelectric pyroelectric performance, Incompatibility with IC technology and other issues, to achieve the effects of easy arrayization and system integration, good long-term stability, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

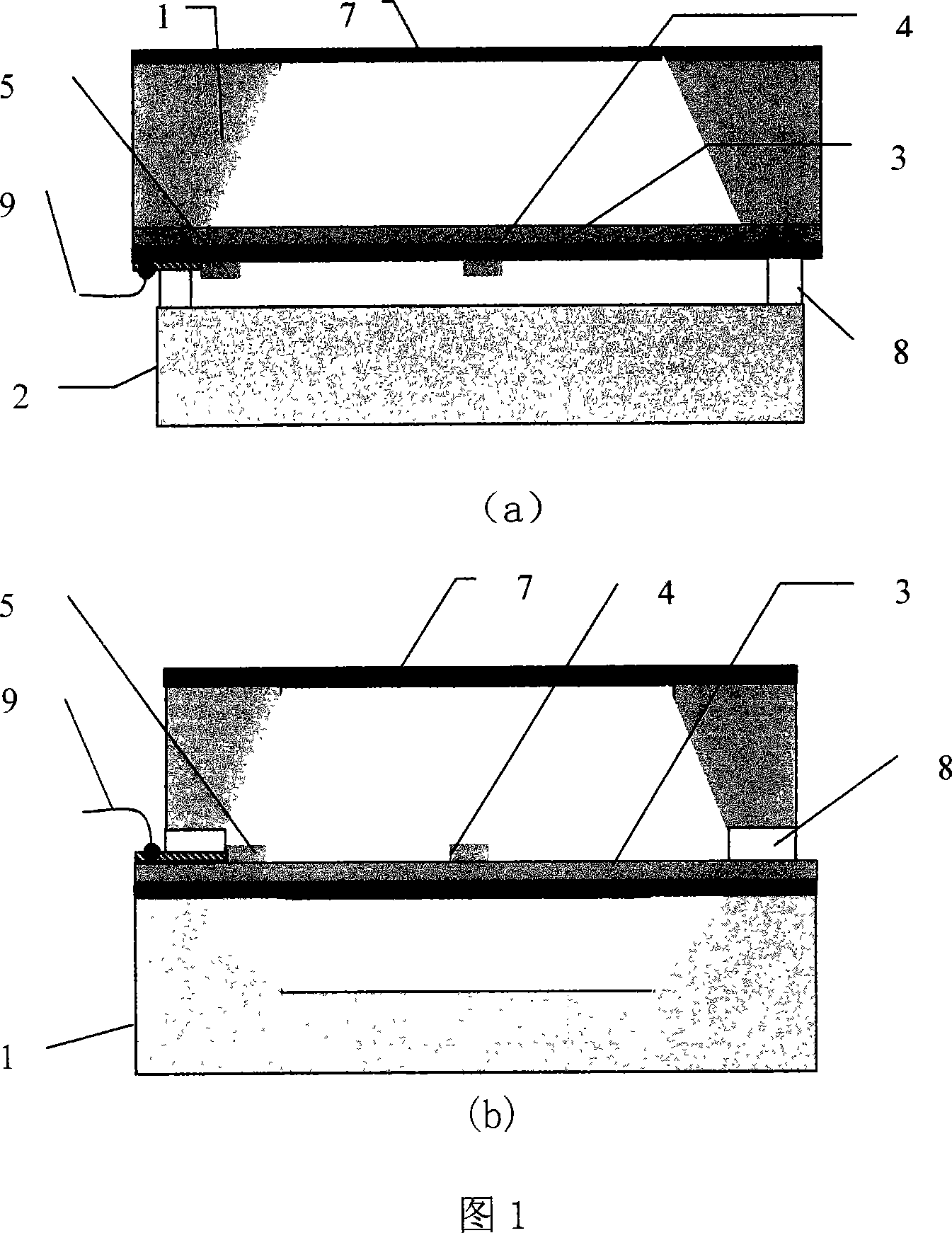

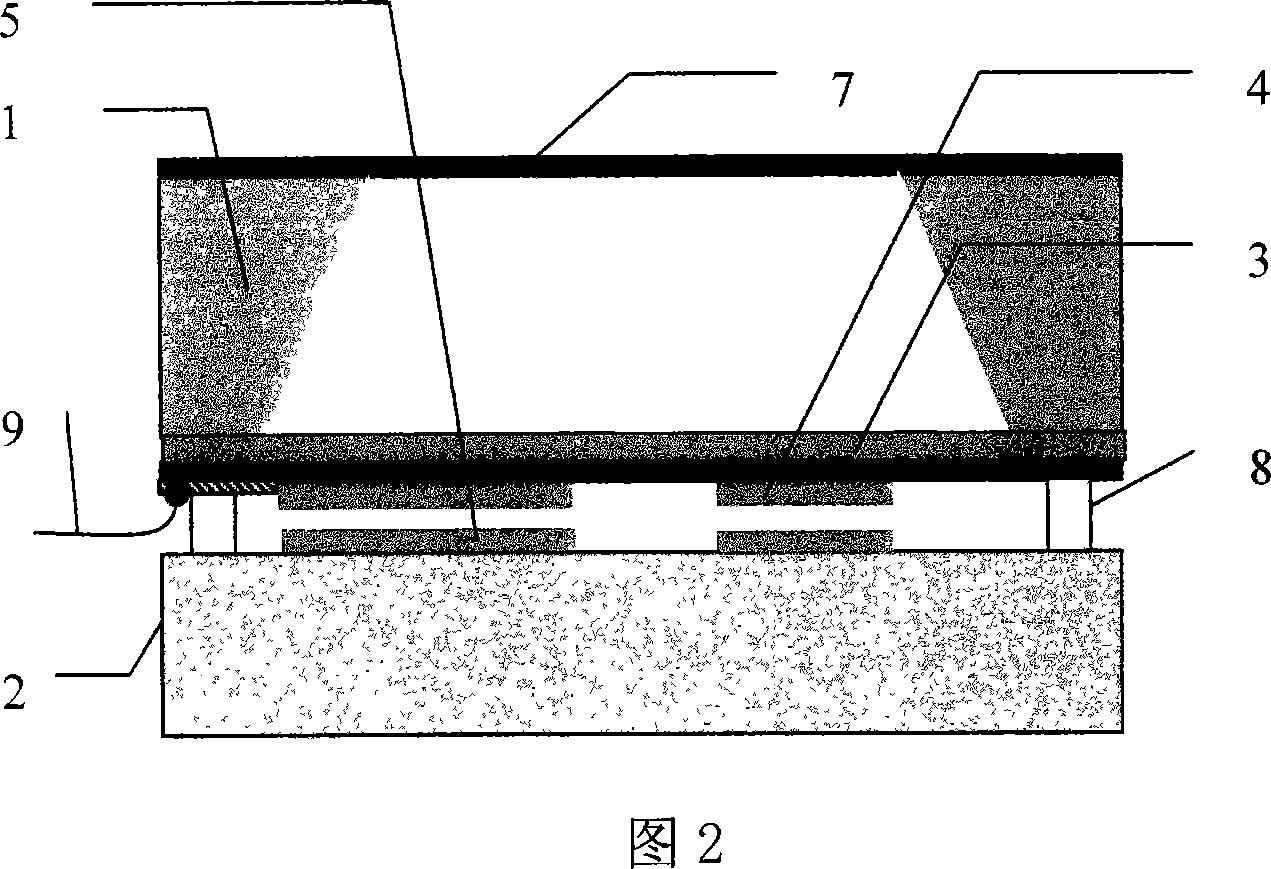

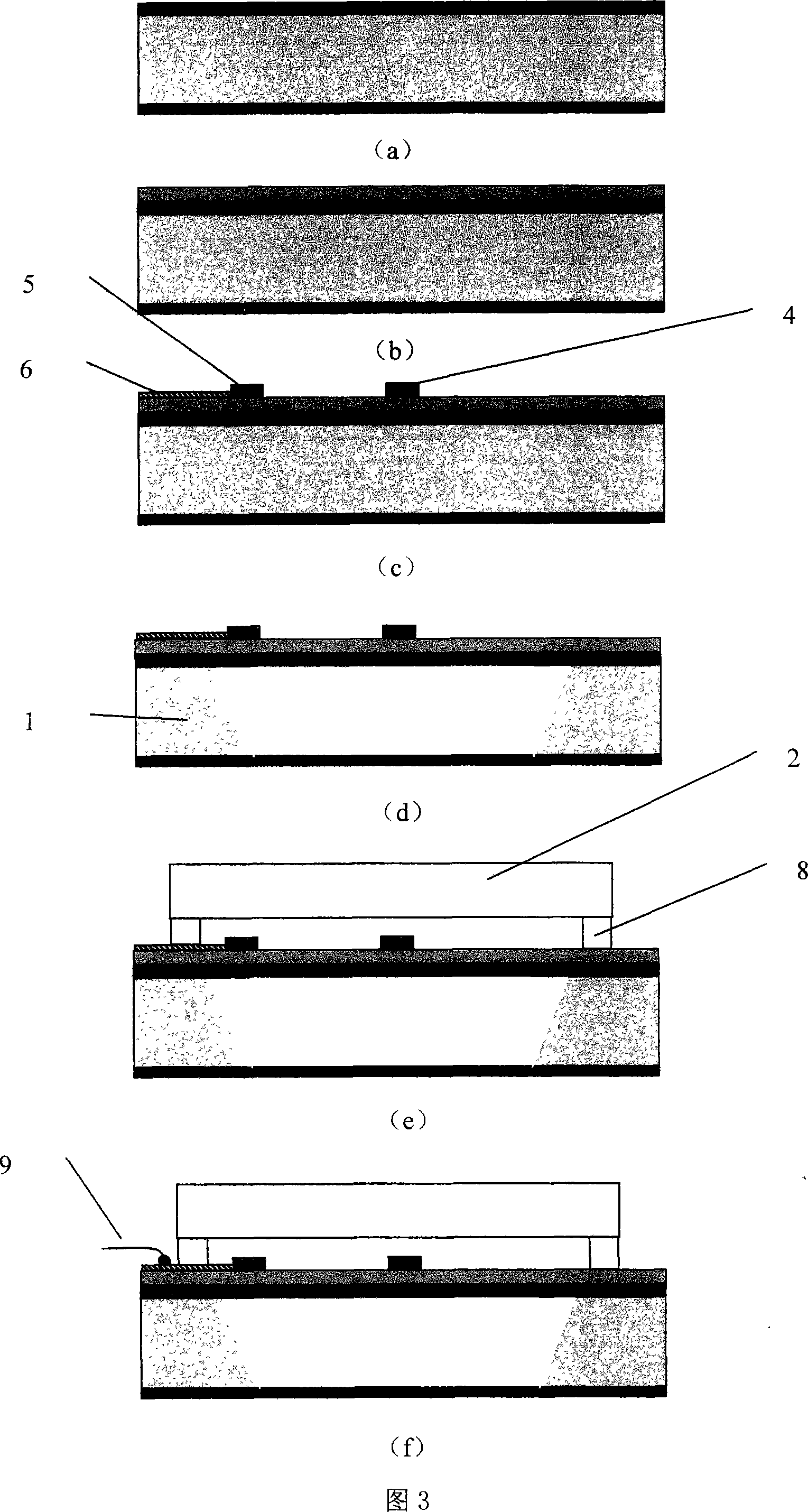

[0037] The technical scheme of the invention is used to manufacture an uncooled infrared detector based on electrothermal excitation / piezoresistive detection micromechanical bridge resonators. Its production process is as follows:

[0038] 1) The original silicon wafer is an N-type, (100) plane silicon wafer with a resistivity of 1-10Ω.cm. Thermal oxidation, oxide layer thickness 0.5μm. (see accompanying drawing 3(a)).

[0039] 2) Deposit a silicon nitride film with a thickness of 0.2-0.3 μm by a low-pressure chemical deposition (LPCVD) process. Lithographic micromechanical bridges on the front side3. (see accompanying drawing 3(b)).

[0040] 3) Deposit polysilicon on the front side to make polysilicon resistors to form the excitation resistor 4 and the pickup resistor 5 . Sputtering aluminum film, photolithographic aluminum wiring, alloying, forming the inner lead 6. (see accompanying drawing 3(c)).

[0041] 4) Deposit a silicon dioxide protective layer on the front si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com