Intelligently-adjusted photovoltaic module mounting support

A technology of intelligent regulation and photovoltaic modules, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules, etc., can solve the problems of reduced manufacturing and installation costs, heavy workload, and inability to generate large amounts of power, so as to reduce water evaporation , saving production cost, simple design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

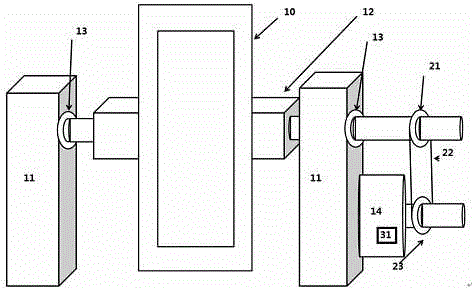

[0022] Such as figure 1 As shown, an intelligently adjusted photovoltaic module installation bracket consists of a support frame 12 for installing photovoltaic modules and a support rod 11 fixed on the ground, and the support frame 12 is mounted on the support rod 11 through a bearing 13. The support rod 11 is provided with a motor 14, the bearing 13 is provided with a driven wheel 21, the motor 14 is provided with a driving wheel 23, the driving wheel 23 and the driven wheel 21 are connected by a transmission belt 22, and the motor 14 An expert system control command 31 is set on the top, the motor 14 intelligently drives the driving wheel 23 through the expert system control command 31, drives the passive wheel 21 to rotate through the transmission belt 22, so that the rotating shaft 13 rotates, and then adjusts the support frame 12, thereby driving the photovoltaic module 10 The intelligent rotation of the expert system, the expert system control command 31 is compos...

Embodiment 2

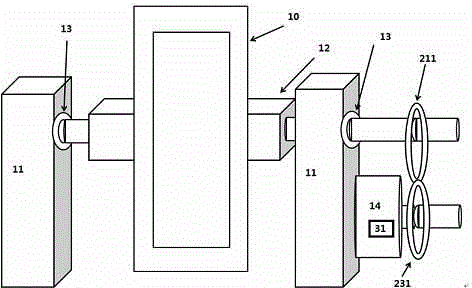

[0024] Such as figure 2 As shown, an intelligently adjusted photovoltaic module installation bracket consists of a support frame 12 for installing photovoltaic modules and a support rod 11 fixed on the ground, and the support frame 12 is mounted on the support rod 11 through a bearing 13. The support rod 11 is provided with a motor 14, the bearing 13 is provided with a driven gear 211, and the motor 14 is provided with a driving gear 231, and the driving wheel 231 and the driven wheel 211 are connected through gear engagement. An expert system control instruction 31 is provided, and the motor 14 intelligently drives the driving gear 231 through the expert system control instruction 31, and drives the passive gear 211 to rotate through the gear, so that the rotating shaft 13 rotates, and then the support frame 12 is adjusted, thereby driving the intelligent rotation of the photovoltaic module 10 , the expert system control instruction 31 is composed of a photovoltaic panel opt...

Embodiment 3

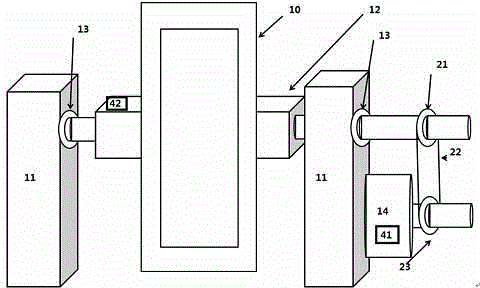

[0026] Such as image 3 As shown, an intelligently adjusted photovoltaic module installation bracket consists of a support frame 12 for installing photovoltaic modules and a support rod 11 fixed on the ground, and the support frame 12 is mounted on the support rod 11 through a bearing 13. The support rod 11 is provided with a motor 14, the bearing 13 is provided with a driven wheel 21, the motor 14 is provided with a driving wheel 23, the driving wheel 23 and the driven wheel 21 are connected by a transmission belt 22, and the support frame 12 is provided with a light intensity sensor 42, and the motor 14 is provided with a receiving device 41, and the receiving device 41 receives the detection signal of the light intensity sensor 42, and the motor 14 intelligently drives the driving wheel 23 through the receiving device 41. The belt 22 drives the driven wheel 21 to rotate, thereby causing the rotating shaft 13 to rotate, and further adjusting the support frame 12 , thereby dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com