Powder crushing method and device

A technology of crushing device and feeding device, which is applied in the direction of grain processing, etc., and can solve the problems of fine powder, reducing the fluidity of powder, and reducing the quality of ceramic products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific embodiments:

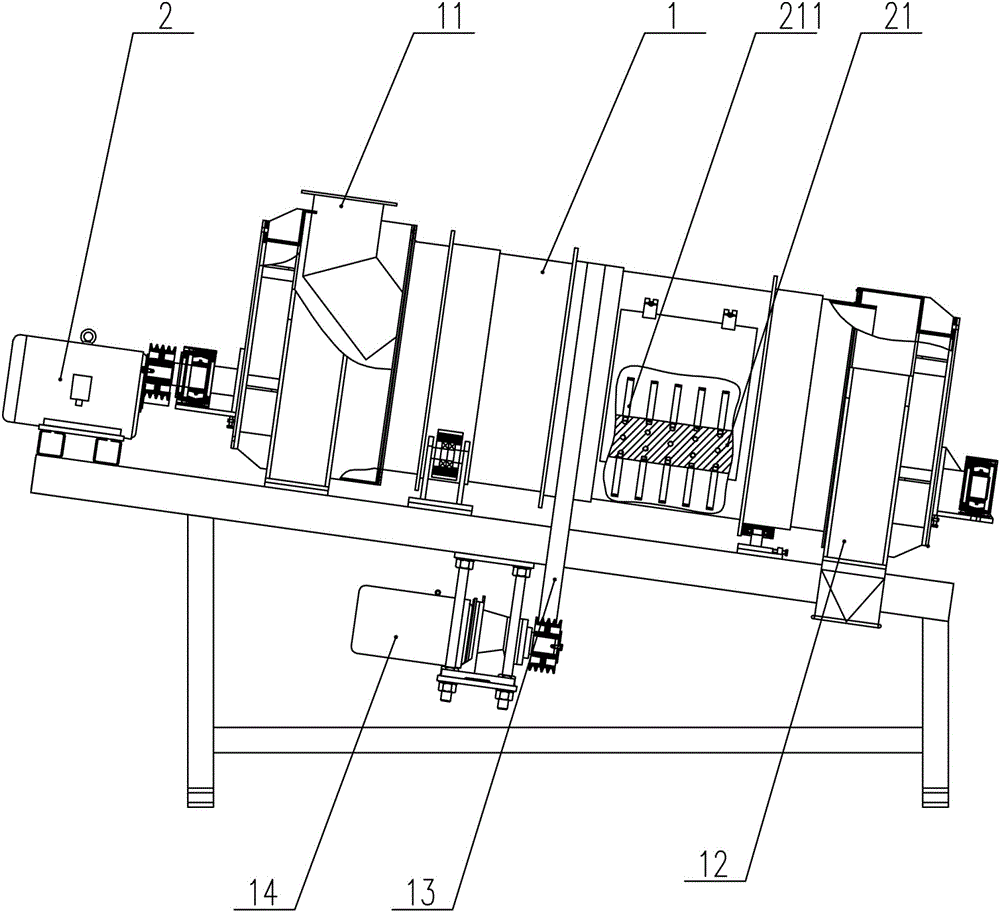

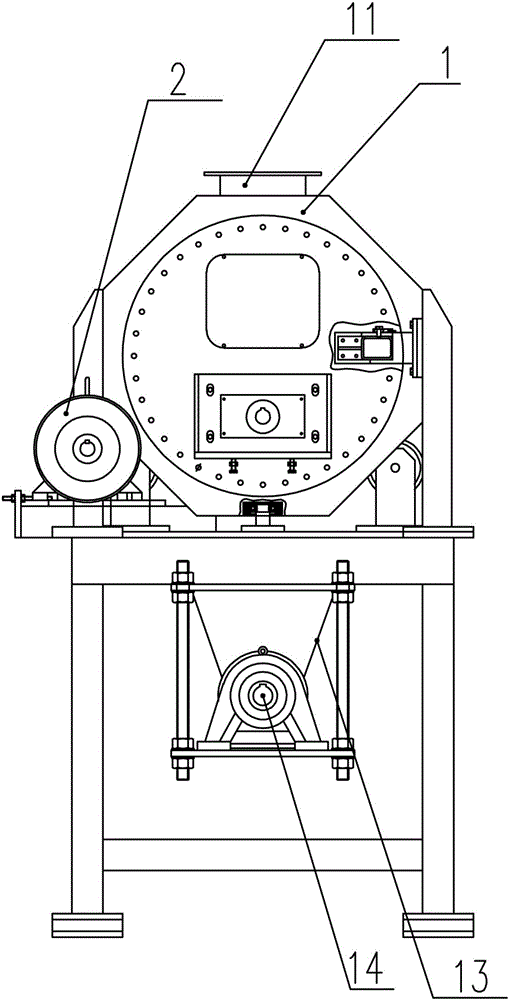

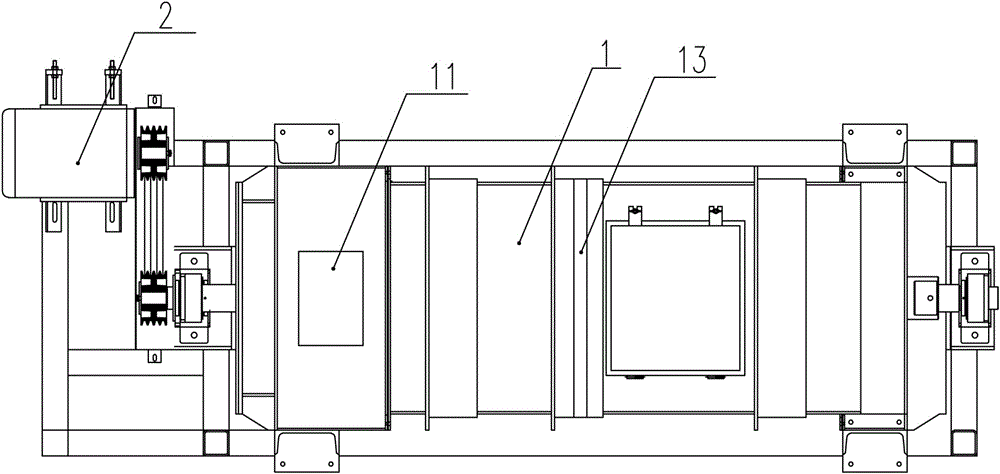

[0016] See attached figure 1 Attached image 3 The structure diagram shown is a powder crushing method and device, wherein the crushing device includes a drum 1 arranged obliquely downward along the feeding direction, a crushing motor 2 arranged on the same inclined plane as the drum 1, and a crushing motor 2 arranged on the same inclined plane as the drum 1. The rolling motor 14 of the vertical plane, preferably, the device of this embodiment includes a support frame. The crushing motor 2 is arranged on one side of the drum 1 and connected to the upper side of the support frame, and is connected to drive the crushing spindle 21. The crushing spindle 21 is provided with Several crushing needles 211 are used to crush powder. The crushing needles 211 are evenly spaced and distributed on the crushing spindle 21. The length of the crushing needles 211 is just in contact with the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com