Movable type agitator for CA mortar

A mortar mixing and mobile technology, applied in cement mixing devices, liquid batching supply devices, clay preparation devices, etc., can solve problems such as difficulty in ensuring the performance of CA mortar and construction fluidity, affecting the quality of irrigation, etc., and achieve guaranteed technical indicators. And the effect of construction quality, compact structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

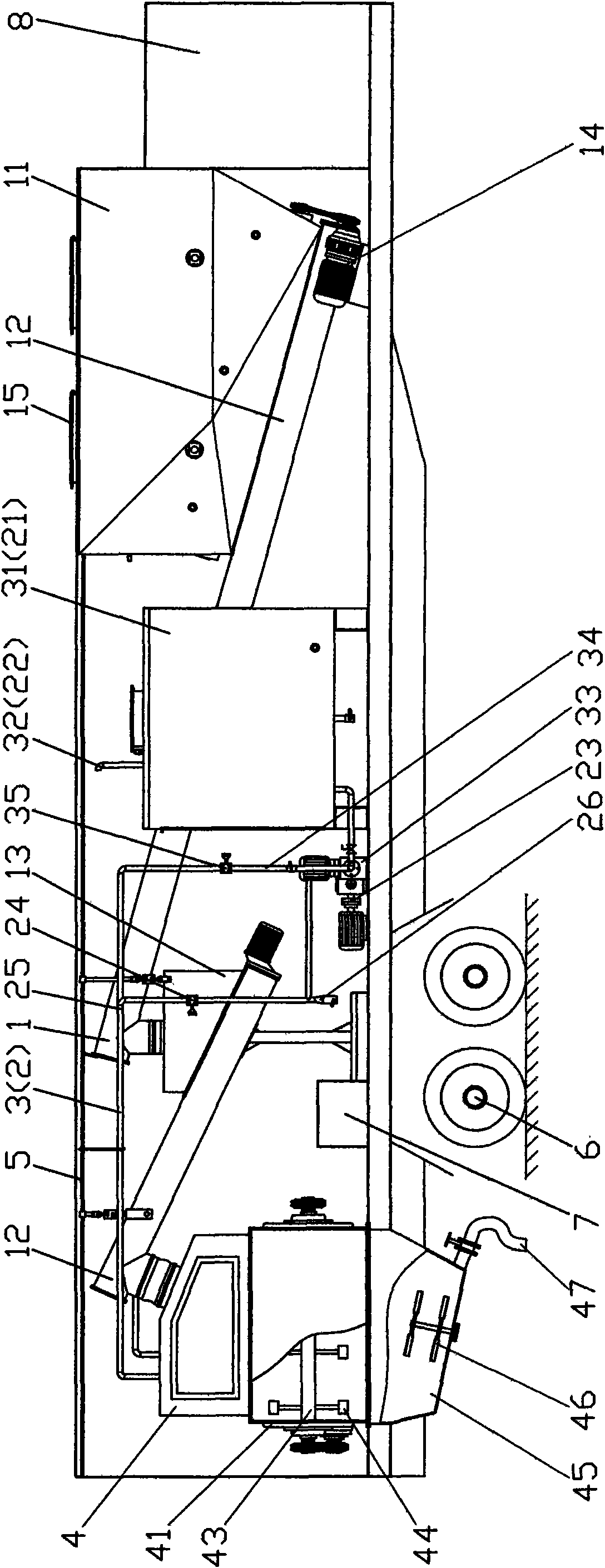

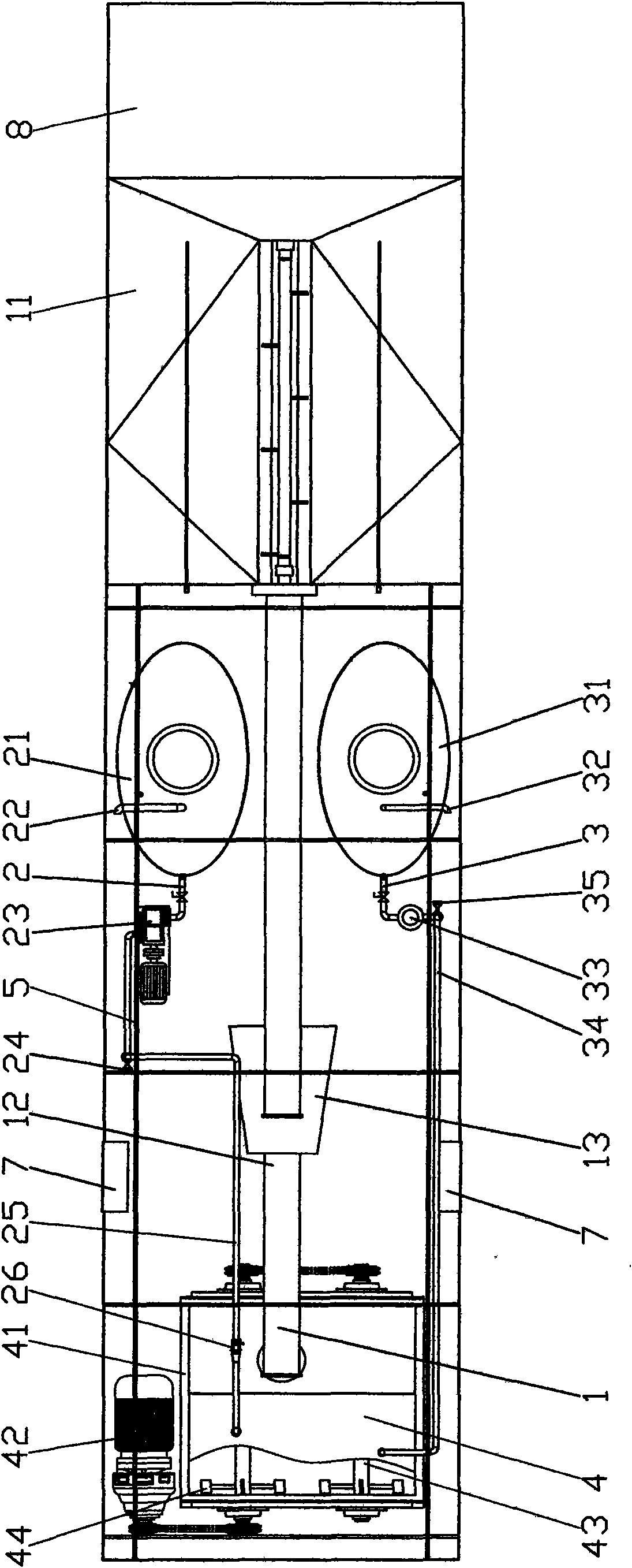

[0012] The present invention mainly consists of a vehicle-mounted box body 5 with wheels 6 at the bottom, an aggregate storage and delivery device 1 placed in the vehicle-mounted box body 5, an emulsified asphalt storage and delivery device 2, a water storage and delivery device 3, and a mortar mixing device 4. The control device 7 placed outside the vehicle compartment 5 and the generator set 8 etc. constitute.

[0013] The aggregate storage and conveying device 1 consists of an aggregate storage bin 11 with a feed inlet 15 on the top, a screw conveying pipeline 12 with a deceleration motor 14 at the bottom of the aggregate storage bin 11, and a metering bin 13 placed in the middle of the spiral conveying pipeline 12 etc., the other end of the screw conveying pipeline 12 is placed on the top of the mixing cylinder 41 of the mortar mixing device 4 . The reduction motor 14 drives the screw shaft in the spiral conveying pipeline 12 to rotate, so that the aggregate moves forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com