Electric truck frame assembly fixing and assembling platform

An assembly table, electric technology, applied in the direction of assembly machines, workbenches, vehicle parts, etc., can solve problems such as the inability to guarantee technical indicators and the inability to assemble the frame assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

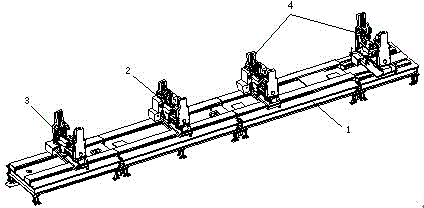

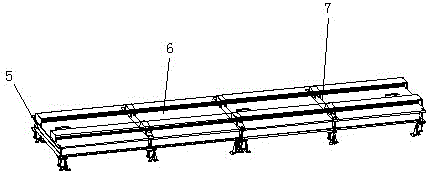

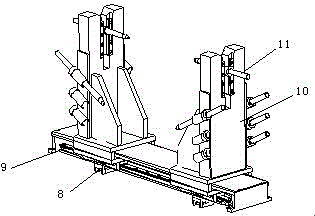

[0036] refer to Figure 1-Figure 5 As shown, an electric truck frame assembly fixed assembly platform includes a base platform 1, a positioning trolley 2, a clamping trolley 1, a clamping trolley 2 4, an electric cylinder driving device (not shown) and a PLC control system (not shown), the base platform 1 provides the assembly platform reference, and can make the positioning trolley 2, clamping trolley one 3, and clamping trolley two 4 move forward and backward in the longitudinal direction, and the base platform 1 is composed of BASE components 1. 5. BASE component 2 6 and adjustable outrigger 7. The positioning trolley 2 includes a roller assembly 8, a linear slide rail assembly 9, a width limiting baffle 10 and a positioning pin 11. The clamping trolley 1 3 includes Roller assembly 12, linear slide rail assembly 13, right width-limiting baffle 14, left width-limiting baffle 15, servo electric cylinder assembly 16, servo electric cylinder assembly 2 17, and left and right in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com