Solid waste crushing and screening skid-mounted equipment

A technology for crushing, screening, and solid waste. It is used in wellbore/well components, earthwork drilling, and flushing wellbore.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The core of the present invention is to provide a solid waste crushing and screening skid-mounted equipment, in order to realize the separation of material particles and the crushing of large particle materials, so that the output material particles meet the material specifications of the use requirements, thereby providing raw materials for subsequent processing and improving resources. Utilization degree and environmental protection performance.

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

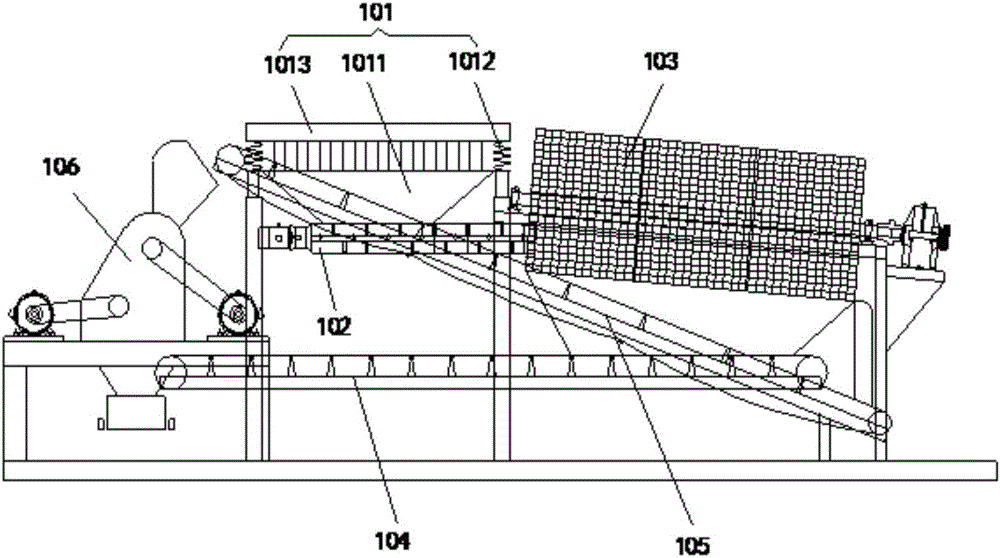

[0016] Please refer to figure 1 , figure 1 It is a flowchart of a specific embodiment of the solid waste crushing and screening skid-mounted equipment provided by the present invention.

[0017] In a specific embodiment, the solid waste crushing and screening skid-mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com