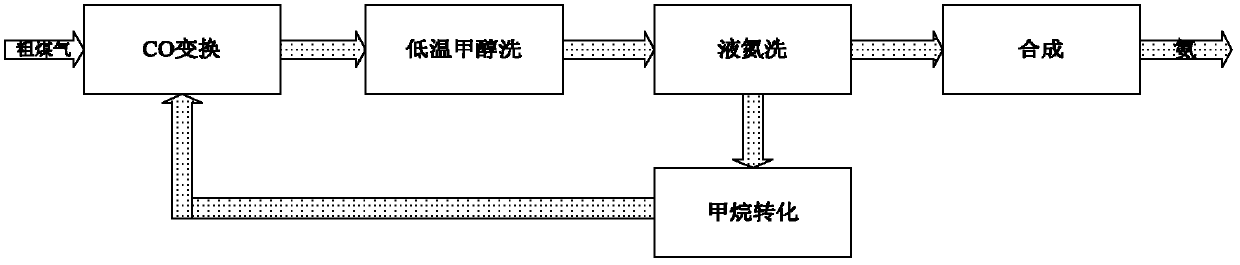

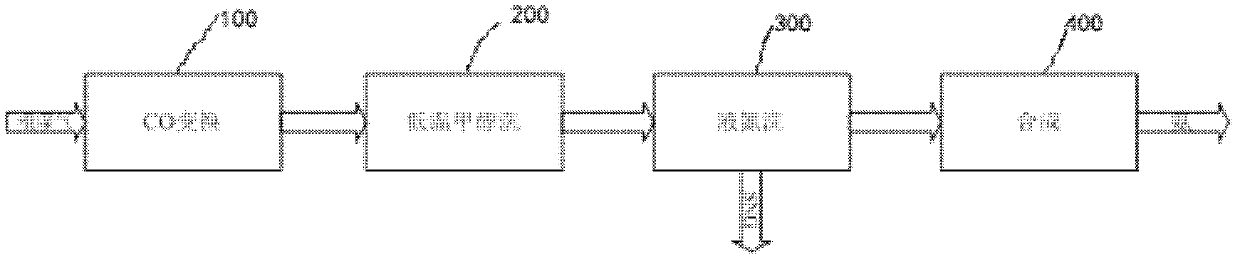

Method and device for combined production of ammonia synthesis gas and SNG by fixed bed crushed coal pressurization and gasification

A crushed coal pressurization and ammonia synthesis gas technology, applied in the direction of gas fuel, hydrogen production, ammonia preparation/separation, etc., can solve the problems of product simplification, low recovery rate, long process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

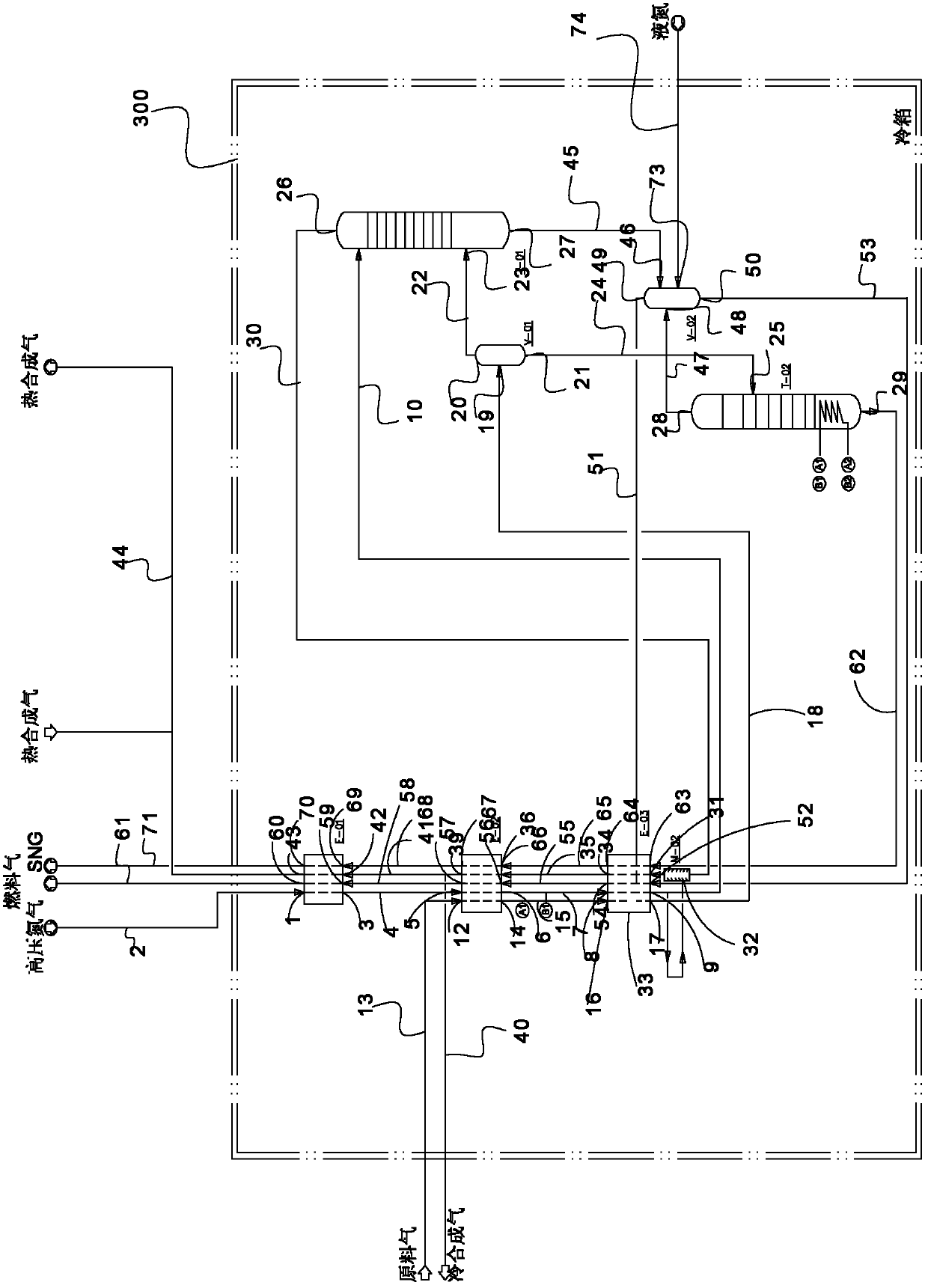

Embodiment 1

[0053] Example 1 adopts as attached image 3 The flow shown. It can be seen from the figure that the entire liquid nitrogen washing device 300 liquid nitrogen washing device includes raw gas coolers E-01, E-02, E-03, nitrogen washing tower T-01, separation tank V-01, and flash tank V-02, methane distillation tower T-02, gas-liquid mixer M-02, gas-gas mixer M-01.

[0054] The medium-pressure nitrogen inlet 1 of the raw gas cooler E-01 is connected to the medium-pressure nitrogen of the air separation through line 2, and the medium-pressure nitrogen outlet 3 of the raw gas cooler E-01 is connected to the middle of the raw gas cooler E-02 through the line 4. The pressure nitrogen inlet 5, the medium pressure nitrogen outlet 6 of the raw gas cooler E-02 are connected to the medium pressure nitrogen inlet 8 of the raw gas cooler E-03 through the pipeline 7, and the liquid nitrogen outlet 9 of the raw gas cooler E-03 passes through the pipeline 10 is connected to the liquid nitrogen i...

Embodiment 2

[0075] Example 2 adopts as attached Figure 4 The flow shown. It can be seen from the figure that the entire liquid nitrogen washing device 300 liquid nitrogen washing device includes raw gas coolers E-01, E-02, E-03, nitrogen washing tower T-01, separation tank V-01, and flash tank v-02, methane distillation tower T-02, gas-liquid mixer M-02.

[0076] The medium-pressure nitrogen inlet 1 of the raw gas cooler E-01 is connected to the medium-pressure nitrogen of the air separation through line 2, and the medium-pressure nitrogen outlet 3 of the raw gas cooler E-01 is connected to the middle of the raw gas cooler E-02 through the line 4. The pressure nitrogen inlet 5, the medium pressure nitrogen outlet 6 of the raw gas cooler E-02 are connected to the medium pressure nitrogen inlet 8 of the raw gas cooler E-03 through the pipeline 7, and the liquid nitrogen outlet 9 of the raw gas cooler E-03 passes through the pipeline 10 is connected to the liquid nitrogen inlet 11 at the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com