Microwave feeding source of ultra-high performance antenna

An ultra-high-performance, antenna technology, applied to antennas, waveguide horns, electrical components, etc., can solve the problem of poor antenna standing wave ratio and cross polarization performance, troublesome processing of feed curved waveguide, and damage to the circular symmetry of the feed pattern In order to achieve high cross-polarization discrimination rate, reduce processing difficulty, and realize the effect of cross-polarization discrimination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

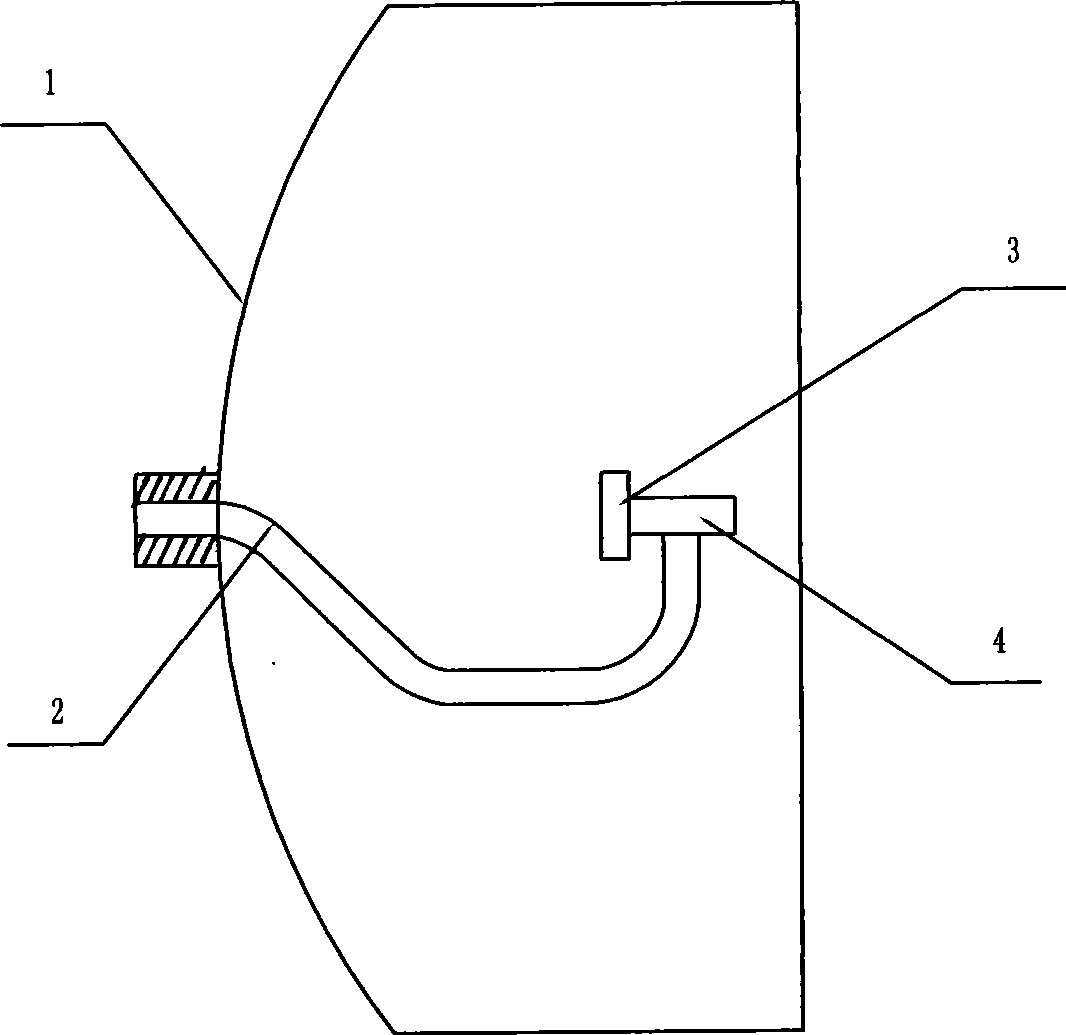

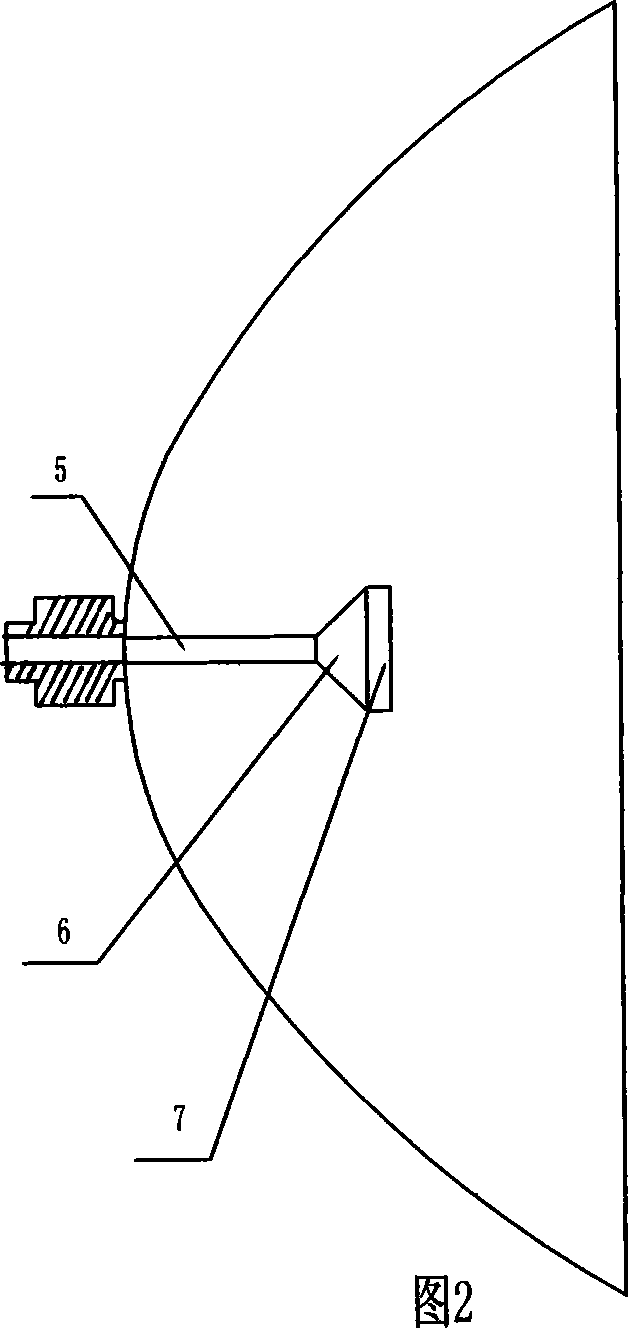

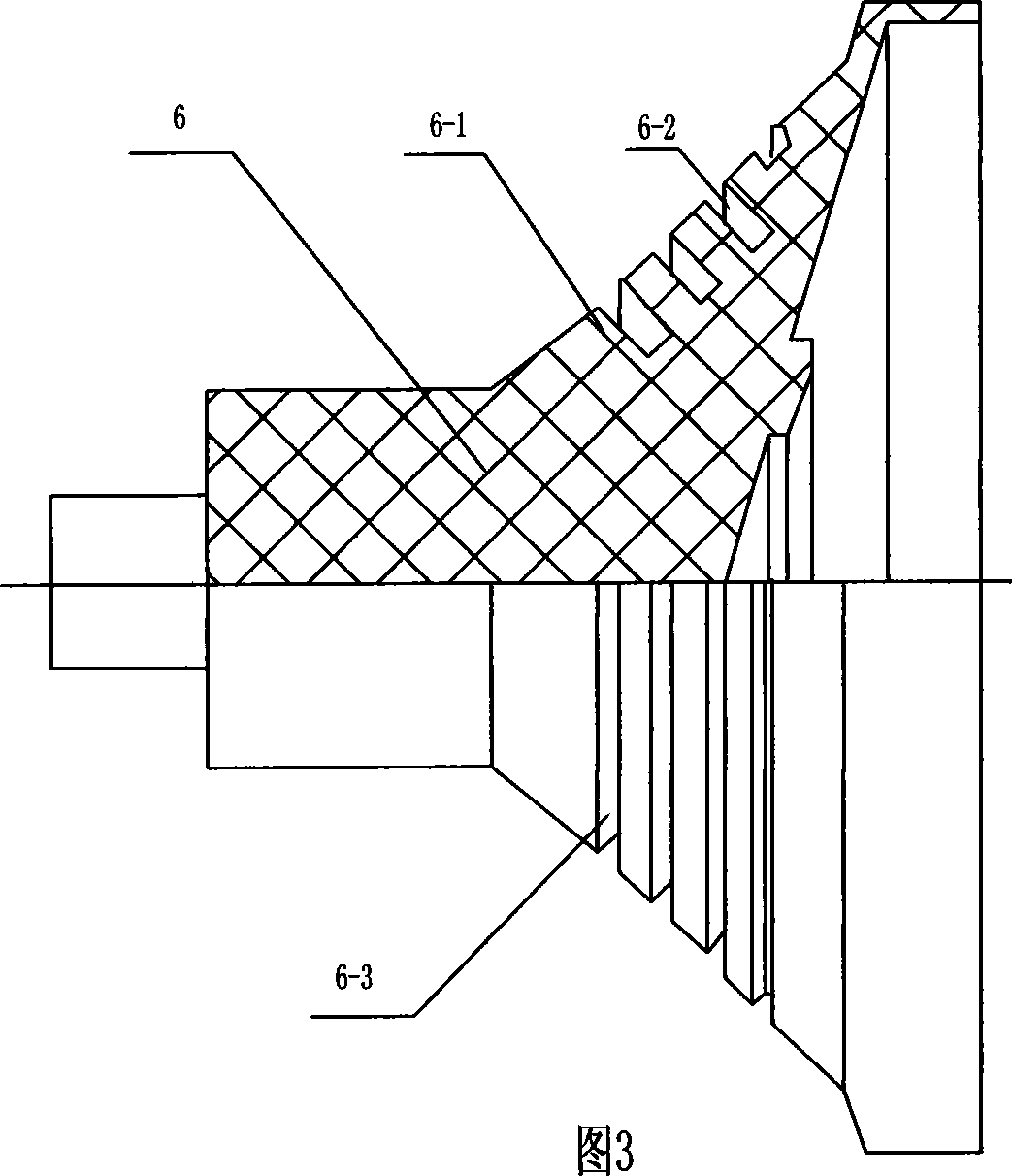

[0021] As shown in Figure 2, the present invention is a microwave feed source for an ultra-high-performance antenna, including a metal circular waveguide 5, a dielectric support 6 and a metal secondary reflector 7 connected to each other and on the same axis. The waveguide 5, the dielectric support 6 and the metal sub-reflector 7 are all circularly symmetrical. The three parts are all precision-processed on a CNC lathe and assembled in order by tight crimping and fitting. The input end of the circular waveguide 5 is compared with the standing wave A small circular / rectangular transition is used for measuring or connecting microwave equipment. A complete set of ultra-high performance antenna can be formed by installing a flange matching the size of the main reflector of the antenna at the appropriate position of the circular waveguide 5. Figure 6 and Figure 7 It is the measured far-field pattern when the above-mentioned feed is installed on a 0.3M parabolic antenna. The diel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com