Steel-concrete composite girder construction technology striding current lines and being parallel to existing lines

A steel-concrete combined beam and construction technology technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of large mutual interference between construction and operation, complex structural design, short construction period, etc., to achieve flexible construction methods, The overall structure of the support is stable and the construction period is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

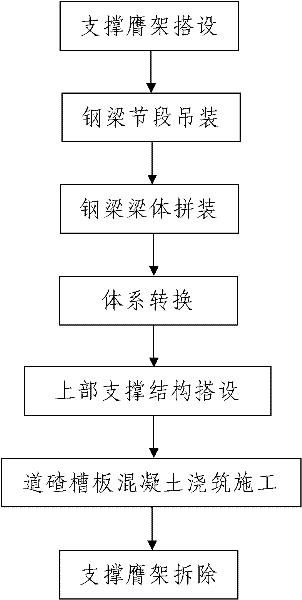

[0051] Such as figure 1 The construction process of a steel-concrete composite beam that crosses the existing line and runs parallel to the existing line includes the following steps:

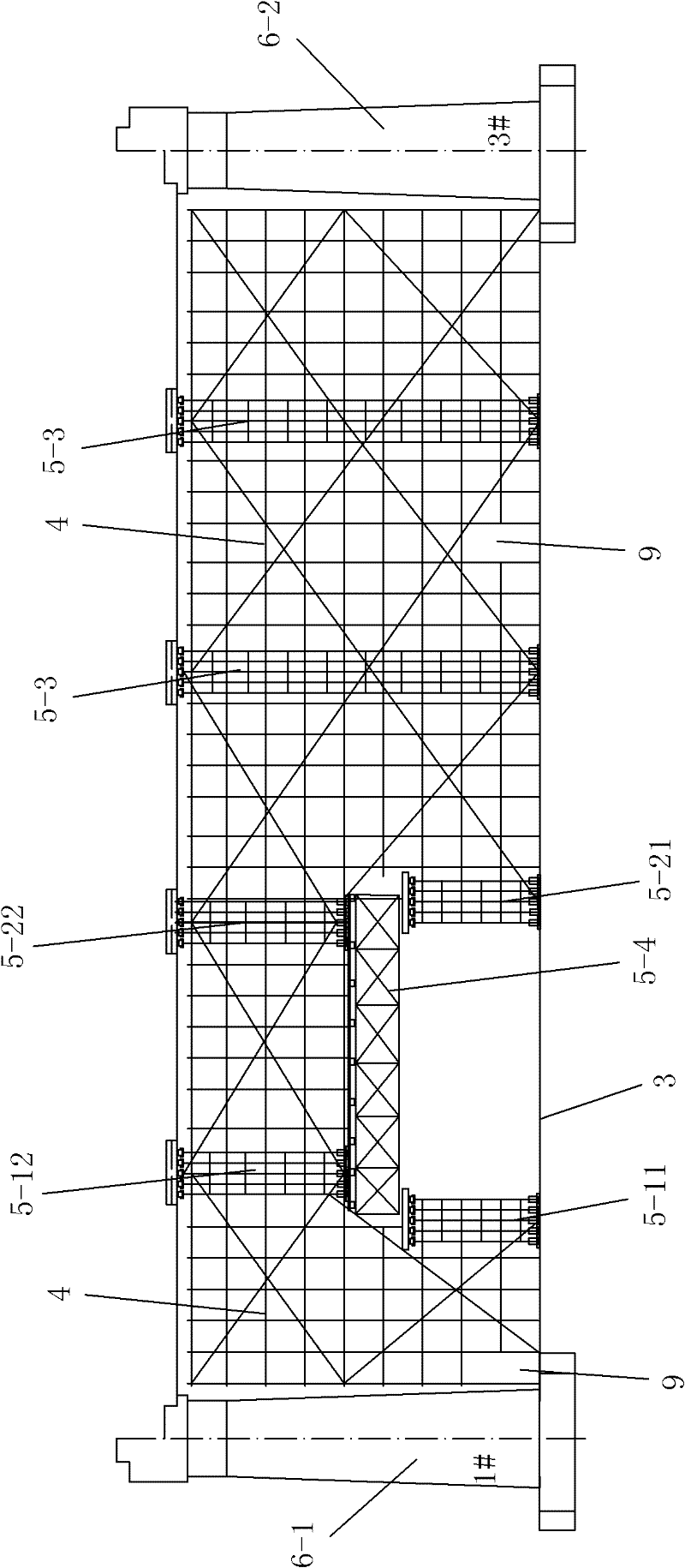

[0052] Step 1. Erection of the supporting frame: the supporting frame includes a plurality of temporary buttresses arranged between the two piers from left to right.

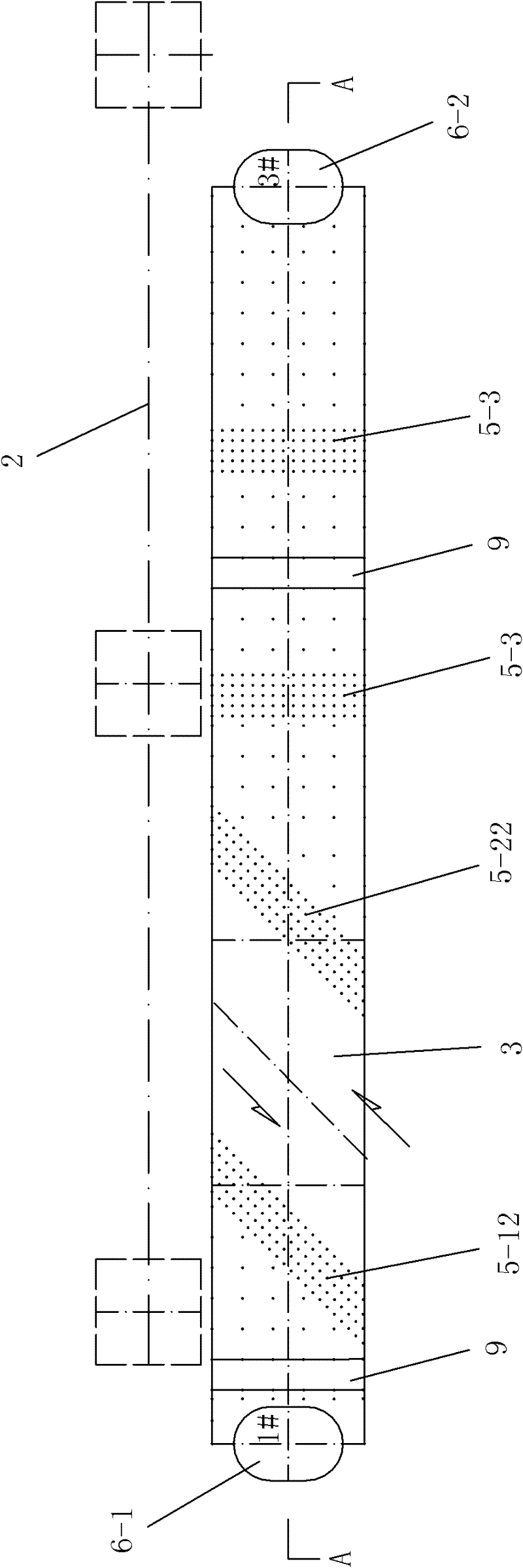

[0053] combine figure 2 , image 3 with Figure 4 , the constructed steel-concrete composite beam 1 is erected between two left and right bridge piers, the newly-built line where the steel-concrete composite beam 1 is located is parallel to the existing operating line and it crosses the existing operating line 3, and the two bridge piers They are respectively a left pier 6-1 and a right pier 6-2 arranged one left and one right, and the left pier 6-1 and the right pier 6-2 are both equipped with mounting supports. The steel-concrete composite beam 1 includes a steel beam body composed of a plurality of steel beam segments 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com