Method and device for cogeneration of synthesis ammonia gas and liquefied natural gas prepared through pressure gasification of crushed coal in fixed bed

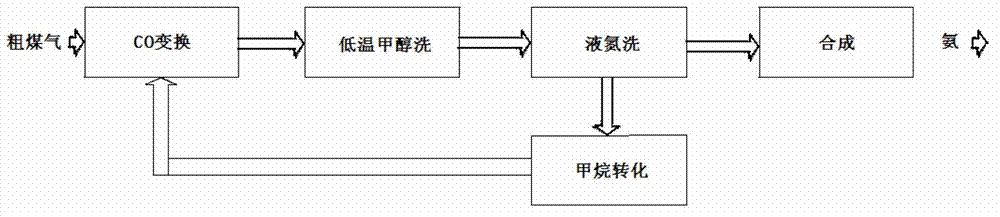

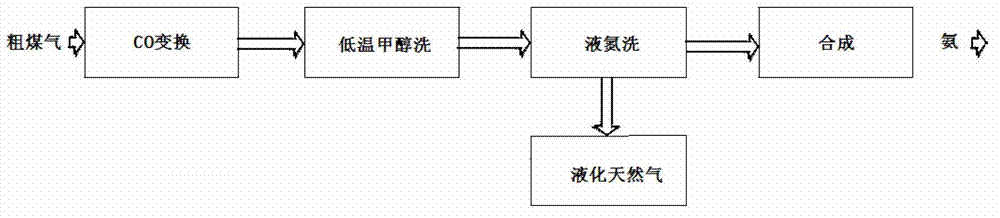

A technology for liquefied natural gas and crushed coal pressurization, which is used in gas fuel, liquid contact hydrogen separation, petroleum industry, etc., and can solve problems affecting plant stability, safety, long-term reliable operation, low recovery rate, and high coupling degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

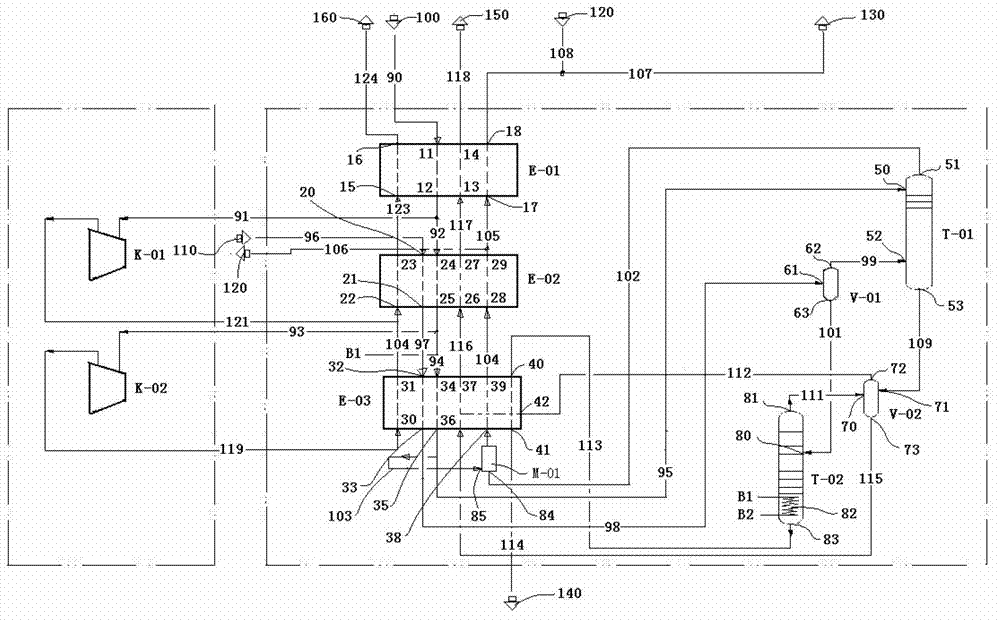

[0057] see image 3 , the fixed-bed pulverized coal pressurized coal gasification ammonia synthesis gas and liquefied natural gas cogeneration device shown in the figure includes high-pressure nitrogen cooler E-01, first raw gas cooler E-02, second raw gas cooler E-03, nitrogen scrubber T-01, methane rectification tower T-02, flash tank V-01, flash tank V-02, nitrogen expander K-01, nitrogen expander K-02.

[0058] The high-pressure nitrogen cooler E-01 has a high-pressure nitrogen inlet 11 , a high-pressure nitrogen outlet 12 , a fuel gas outlet 13 , a fuel gas inlet 14 , a nitrogen inlet 15 , a nitrogen outlet 16 , a synthesis gas inlet 17 and a synthesis gas outlet 18 .

[0059] The first raw gas cooler E-02 has raw gas inlet 20, raw gas outlet 21, nitrogen inlet 22, nitrogen outlet 23, high-pressure nitrogen inlet 24, high-pressure nitrogen outlet 25, fuel gas inlet 26, fuel gas outlet 27, synthesis gas Inlet 28, syngas outlet 29;

[0060] The second raw gas cooler E-03 ...

Embodiment 2

[0079] see Figure 4 , the fixed-bed pulverized coal pressurized coal gasification ammonia synthesis gas and liquefied natural gas co-production device of this embodiment is basically the same as that of Embodiment 1, except that 25 high-pressure nitrogen outlets separate high-pressure nitrogen delivery pipelines 93 and 94, and high-pressure nitrogen delivery pipeline 93 It is connected to the inlet of the nitrogen expander K-02, and the high-pressure nitrogen delivery pipeline 94 is connected to the high-pressure nitrogen inlet 34 of the second raw material gas cooler E-03. The raw material gas outlet 21 divides the raw material gas output pipeline 97 and the raw material gas output branch line A1, the raw material gas output branch line A1 is connected to the inlet of the reboiler 82 at the lower part of the methane distillation tower T-02, and the raw material gas output line 97 is connected to the first The raw material gas inlet 32 on the raw material gas cooler E-03 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com