PVC plastic pipe manufacturing and forming method

A molding method and technology of plastic pipes are applied in the direction of manufacturing tools, drying solid materials, and drying solid materials without heating. It can solve the problems of PVC plastic pipe correction, PVC plastic pipe diameters, and cumbersome mold replacement processes, etc., to achieve Guaranteed diameter, improved cylindricity, and the effect of avoiding cumbersome processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

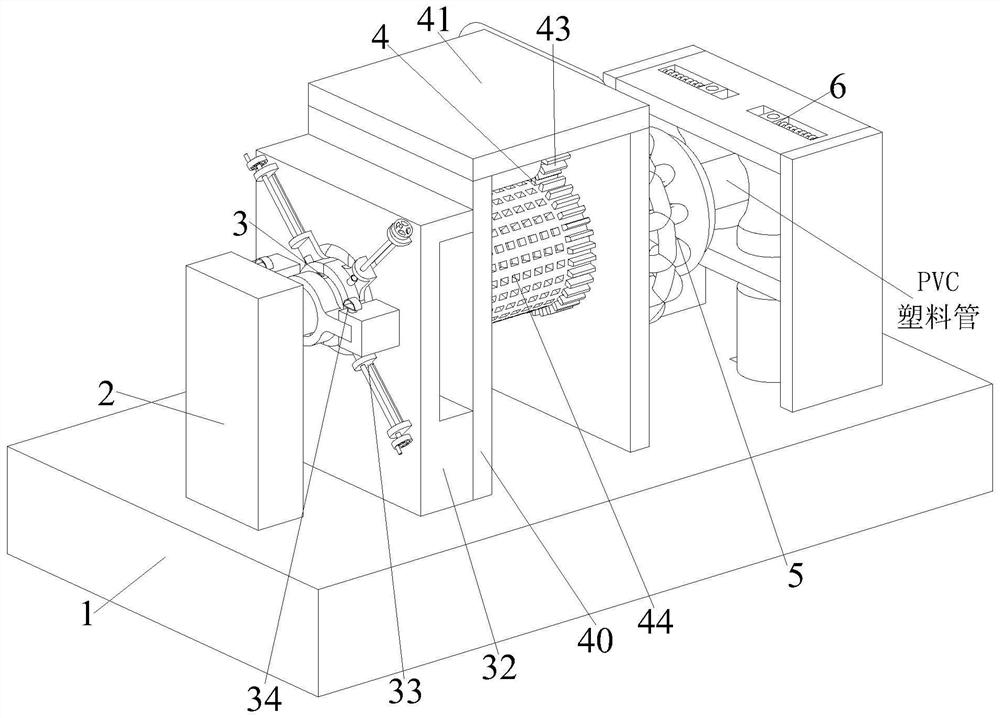

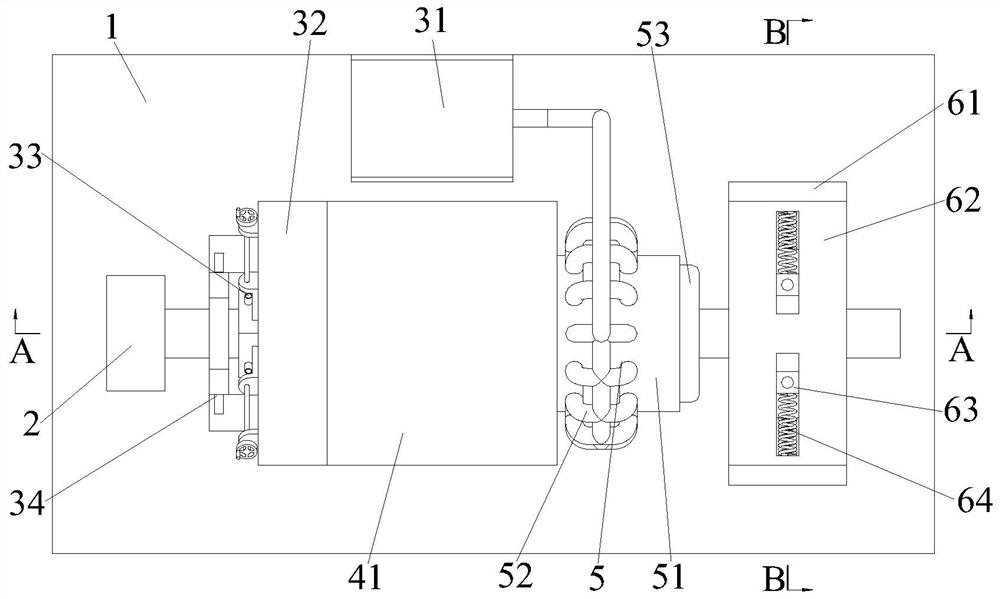

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 9 , to further elaborate the present invention.

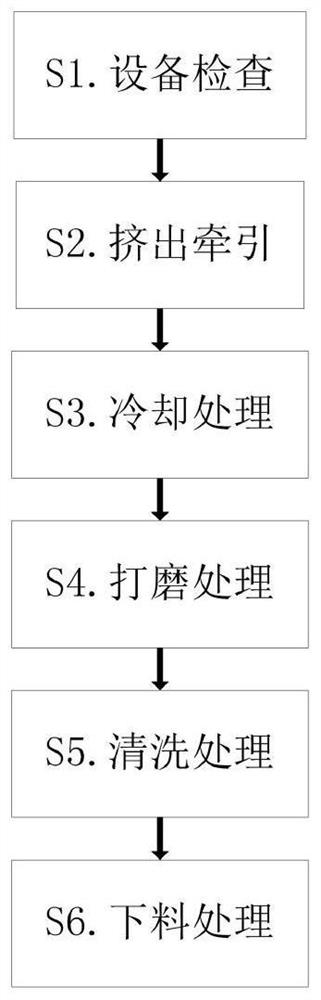

[0042] A PVC plastic pipe production molding method, the specific molding method is as follows:

[0043] S1. Equipment inspection: Before using PVC plastic pipes to make molding equipment, inspect them;

[0044] S2. Extrusion traction: After the equipment inspection is completed, the PVC plastic pipe is extruded through the hot-melt extruder 2, and the extruded PVC plastic pipe passes through the cooling device 3, the grinding device 4 and the cleaning device 5 in sequence, and Placed in the driving device 6 for traction;

[0045] S3. Cooling treatment: during the process of pulling the PVC plastic pipe by the driving device 6, it is cooled by the cooling device 3;

[0046] S4. Grinding treatment: during the cooling process of the PVC plastic pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com