Adhesive for PP substrate as well as preparation method and application of adhesive

An adhesive and substrate technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as fire and environmental hazards, and achieve improved adhesion, high film strength and adhesion. Focus on and avoid the effect of cumbersome process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

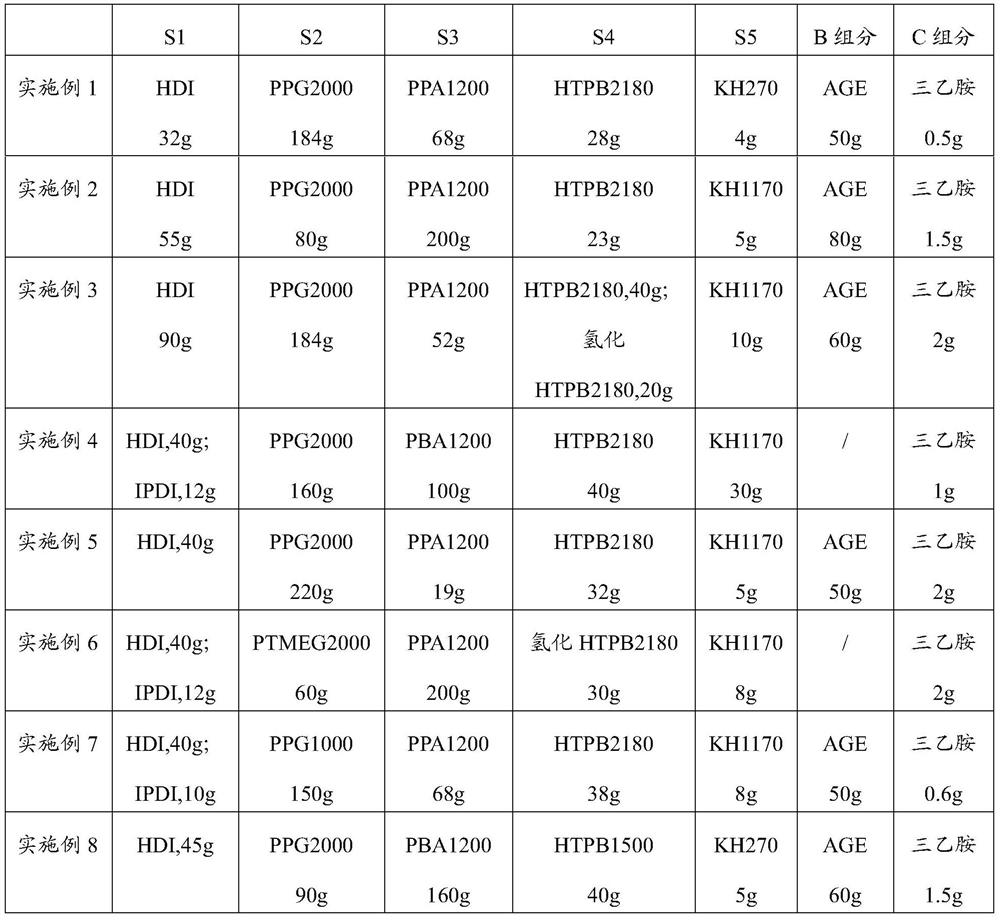

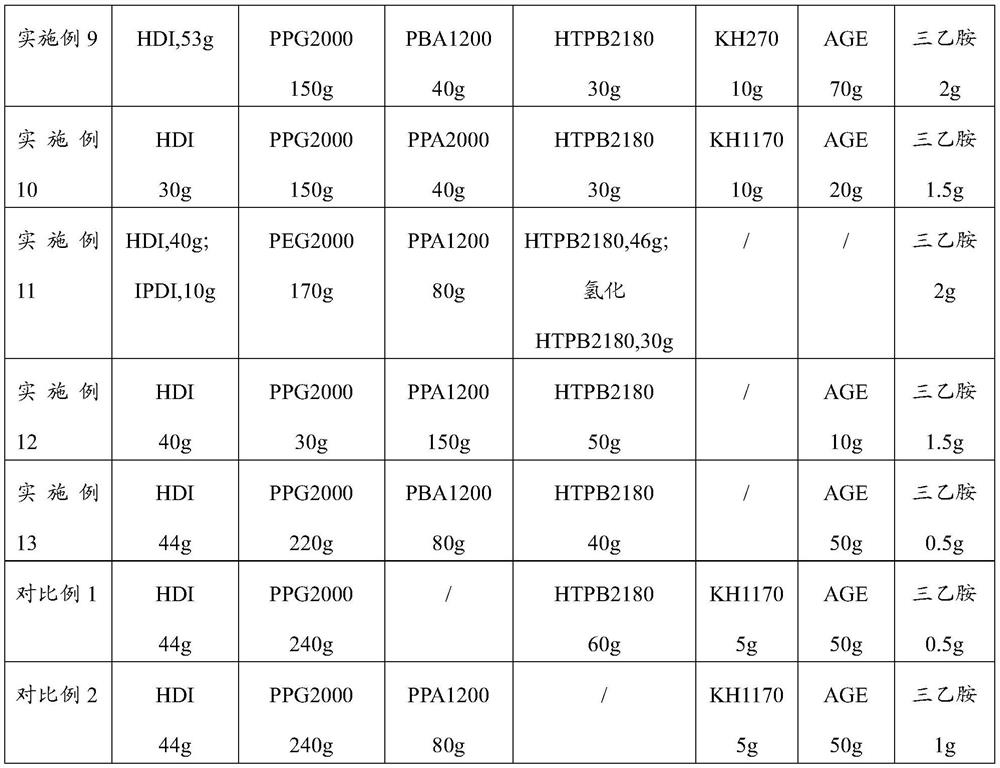

[0093] Embodiment 1-13 (being S1-13) and comparative example 1-2 (being D1-2)

Embodiment 1

[0095] 32g HDI (S1), 184g dehydrated PPG2000 (S2), 68g PPA1200 (S3), 28g HTPB (S4), 0.1g 8108 catalyst were added to a 1L four-necked round bottom flask equipped with a nitrogen inlet and outlet. The mixture was stirred at 80° C. (denoted as reaction temperature 1) until the NCO reached the theoretical value (denoted as NCO theoretical value a) of 1.00%. Lower the temperature to 50°C (recorded as reaction temperature 2), add 4g KH270 (S5), stir and continue the reaction until NCO reaches a new theoretical value (recorded as NCO theoretical value b) of 0.65%. Add 0.5g of triethylamine (component C) to the system, stir evenly to obtain adhesive a; test the viscosity of adhesive a is 11200cp; then add 50g of AGE (component B) to the adhesive a system Stir and dilute to obtain adhesive b, whose viscosity is tested to be 8000cP; adhesive b is sealed and stored.

[0096] Embodiment 2-13 and comparative example 1-2 are prepared according to the method in embodiment 1; It has only fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com