A kind of polyurethane emulsion and its preparation and use

A technology of polyurethane emulsion and emulsion, applied in the direction of polyurea/polyurethane adhesive, adhesive type, bonding method, etc., can solve the problems of affecting construction efficiency, high viscosity of prepolymer, etc., achieve low viscosity, improve adhesion Focus on and avoid the effect of cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

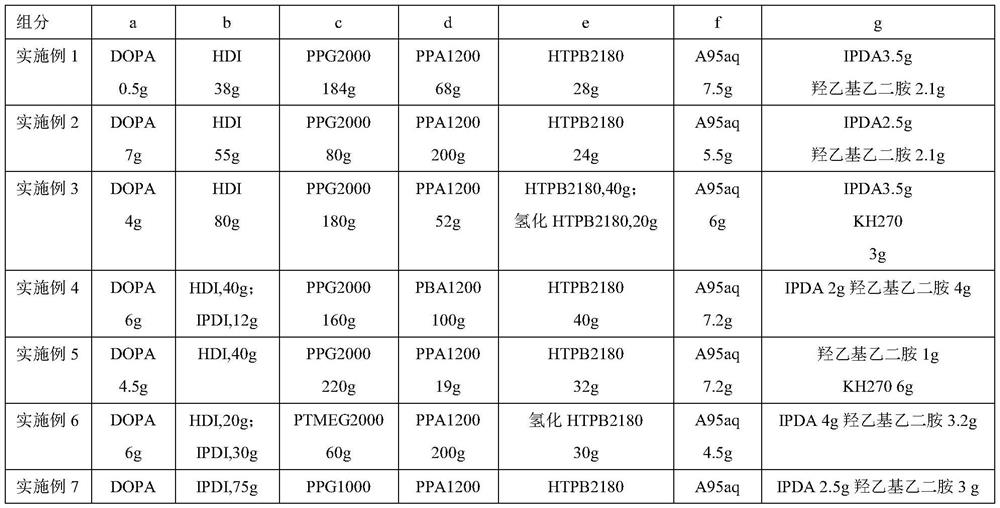

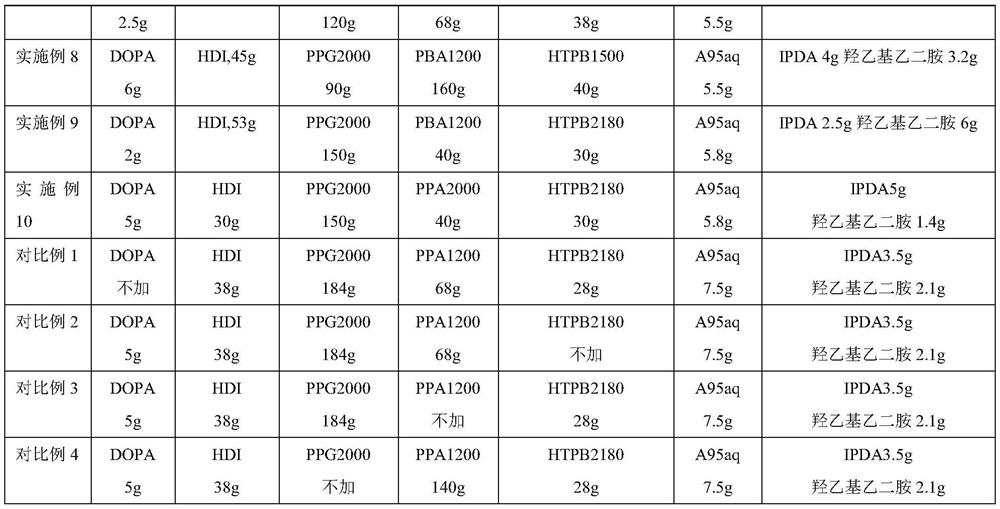

Embodiment 1

[0072] 38g HDI (component b), 184g dehydrated PPG2000 (component c), 68g PPA1200 (component d), 28g HTPB (component e), 0.1g bismuth neodecanoate (catalyst, other examples and The same amount of comparative example) and 25g of acetone (acetone addition amount 1) were added to a 1L four-necked round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 80°C (referred to as reaction temperature 1) until NCO reached the theoretical value of 1.65wt %. The prepolymer was dissolved in 451 g of acetone (acetone addition amount 2) and cooled to 40°C (referred to as reaction temperature 2), 0.5 g of DOPA (component a), 2.1 g of hydroxyethylethylenediamine ( Component g), 15g acetone of 3.5g IPDA (component g) (other embodiments and comparative example consumption are the same) are added in the acetone solution dissolved with prepolymer while vigorously stirring, 7.5g A95 aqueous solution is added after 5min. , stirred for an additional 15 min, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com