Composite molded body and manufacturing method thereof

A composite molded body and manufacturing method technology, applied to chemical instruments and methods, synthetic resin layered products, and other household appliances, can solve the problems that the strength and rigidity of the composite molded body cannot reach the target value, and the joint strength cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

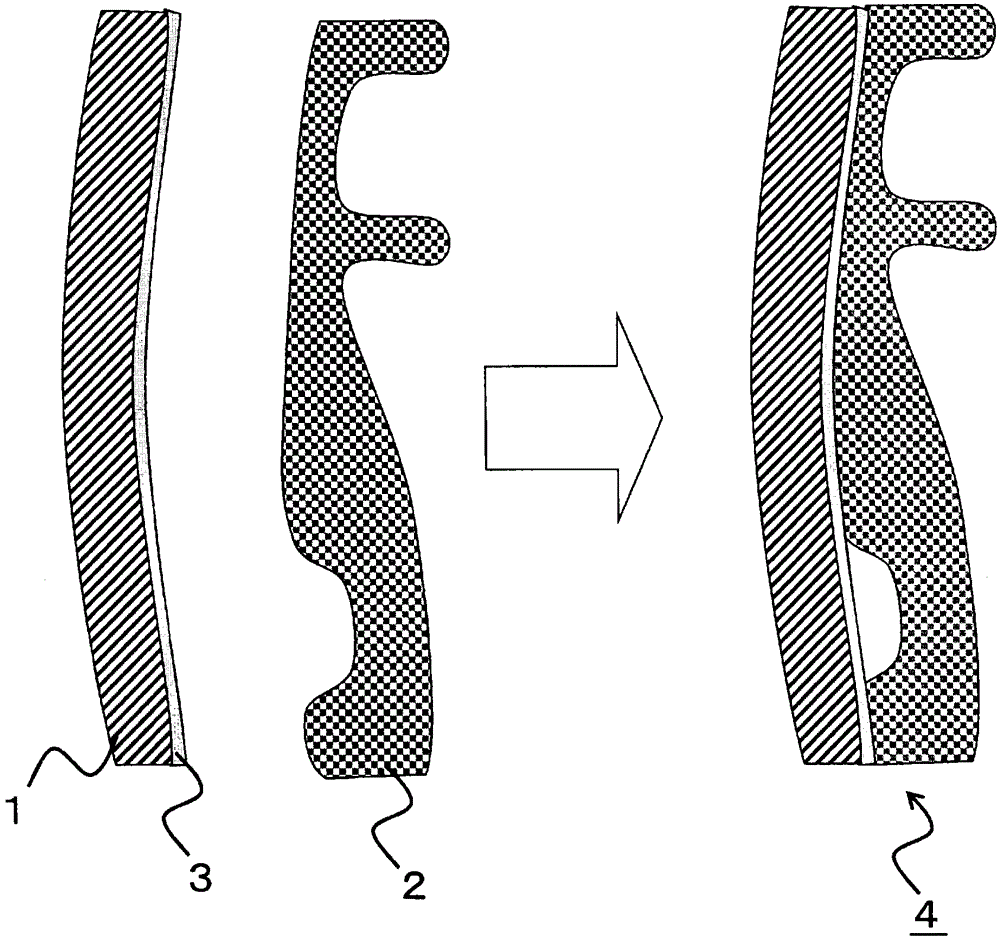

[0040] figure 1 A method for producing a composite molded body according to an embodiment of the present invention and a structural example of a preform in the present invention are shown in . figure 1 Among them, 1 represents the preform a, and 2 represents the preform b. In addition, 3 represents a layer using a thermoplastic resin C having a relatively low crystallization temperature (for example, low crystallization temperature PPS [low crystallization temperature copolymerized polyphenylene sulfide]). A layer 3 made of thermoplastic resin C is integrally formed in advance on one surface of the preform a ( 1 ). The preform a (1) and the preform b (2) are respectively made of thermoplastic resin A and thermoplastic resin B (for example, PPS with a normal crystallization temperature) whose crystallization temperature is relatively high compared with thermoplastic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com