Polyurethane binder and application thereof

An adhesive, polyurethane technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of insufficient moisture and heat resistance, poor adhesion, etc., to improve the moisture and heat resistance, cohesion and Heat resistance improvement, effect of improving heat resistance and hydrolysis resistance under moist heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of the hydroxyl component:

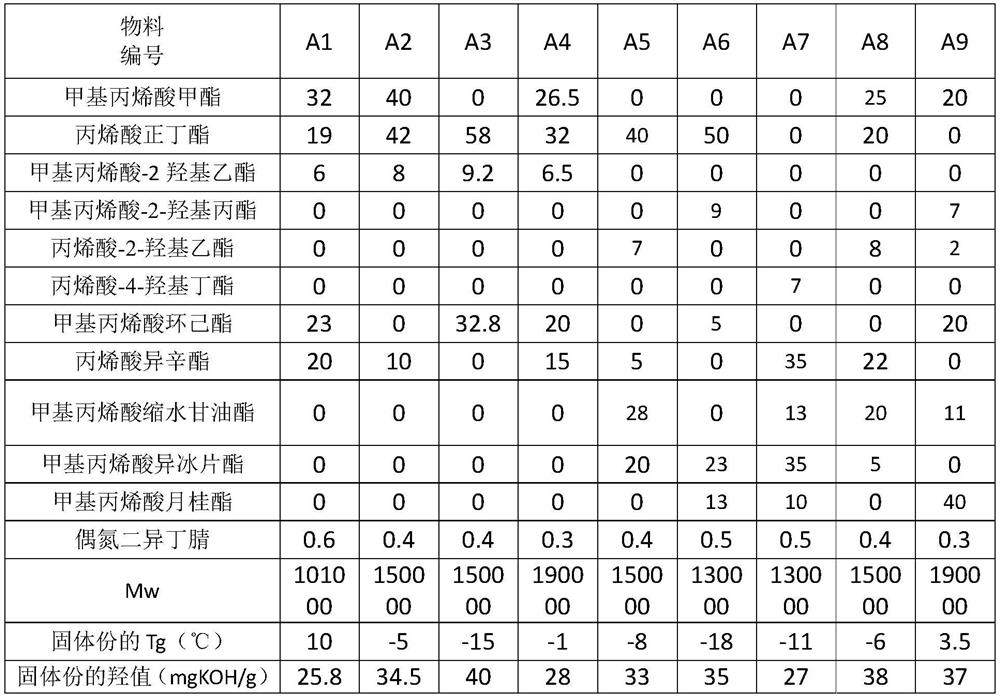

[0031] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the reaction kettle of the environment, add 100 parts by mass of ethyl acetate, heat to 75 ° C, 19 parts by mass of n-butyl acrylate, 32 parts by mass of methyl methacrylate, 23 parts by mass of cyclohexyl methacrylate, 6 parts by mass of 2-hydroxyethyl methacrylate, 20 parts by mass of isooctyl acrylate and 0.6 parts by mass of azobisisobutyronitrile are uniformly mixed and added dropwise to the reaction system within 2 hours, and then cooled to room temperature after 3 hours of heat preservation , to obtain the hydroxyl-containing methacrylate polymer A1 solution, the content of the hydroxyl-containing methacrylate polymer is 50wt%, and the relevant physical parameters of the hydroxyl-containing methacrylate polymer A1 are shown in Table 1.

[0032] Preparation of curing agent:

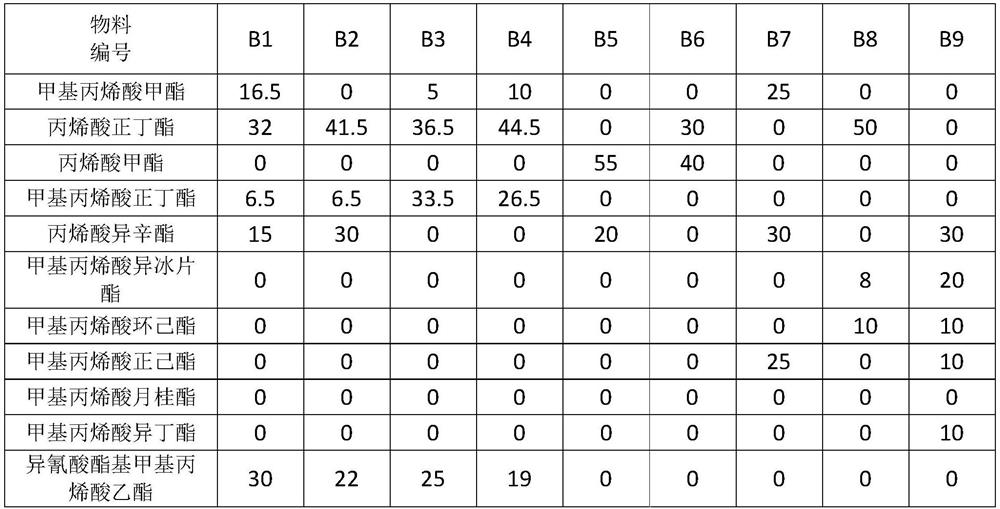

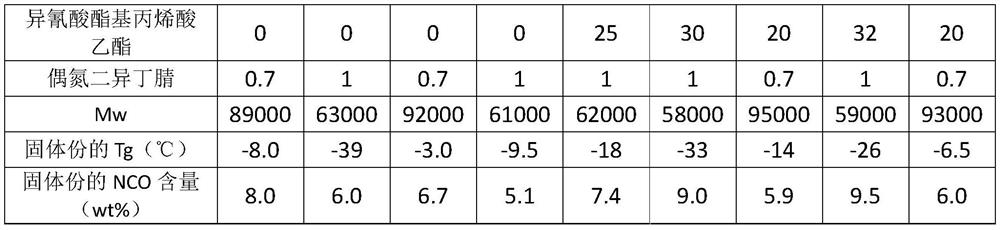

[0033] Equipped with mechanical stirring, thermometer, reflux conden...

Embodiment 2

[0037] Preparation of the hydroxyl component:

[0038] Equipped with mechanical stirring, thermometer, reflux condenser, N 2In the reaction kettle of the environment, add 100 mass parts of ethyl acetate by mass parts, heat to 75 ° C, 32 mass parts of n-butyl acrylate, 26.5 mass parts of methyl methacrylate, 20 mass parts of cyclohexyl methacrylate, 6.5 parts by mass of 2-hydroxyethyl methacrylate, 15 parts by mass of isooctyl acrylate and 0.3 parts by mass of azobisisobutyronitrile were uniformly mixed and added dropwise to the reaction system within 2 hours, and kept warm for 3 hours and then lowered to room temperature , to obtain the hydroxyl-containing methacrylate polymer A4 solution, the content of the hydroxyl-containing methacrylate polymer A4 is 50 wt%, and the relevant physical parameters of the hydroxyl-containing methacrylate polymer A4 are shown in Table 1 .

[0039] The preparation of curing agent is with embodiment 1

[0040] Preparation of polyurethane binde...

Embodiment 3

[0043] Preparation of the hydroxyl component:

[0044] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the reaction kettle of the environment, add 100 parts by mass of ethyl acetate, heat to 75 ° C, and add 58 parts by mass of n-butyl acrylate, 32.8 parts by mass of cyclohexyl methacrylate, 9.2 parts by mass of methacrylic acid-2-hydroxy Ethyl ester and 0.4 parts by mass of azobisisobutyronitrile were mixed evenly and then continuously added dropwise to the reaction system within 2 hours, kept warm for 3 hours and then lowered to room temperature to obtain a hydroxyl-containing methacrylate polymer A3 solution, containing hydroxyl The content of the methacrylate polymer A3 is 50wt%, and the relevant physical parameters of the hydroxyl-containing methacrylate polymer A3 are shown in Table 1.

[0045] Preparation of curing agent:

[0046] Equipped with mechanical stirring, thermometer, reflux condenser, N 2 In the reaction kettle of the environment, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com