Adhesive for pp substrate and preparation method and application thereof

A technology of adhesives and substrates, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as fire and environmental hazards, and achieve improved adhesion, high film strength and adhesion Focus on and avoid the effect of cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

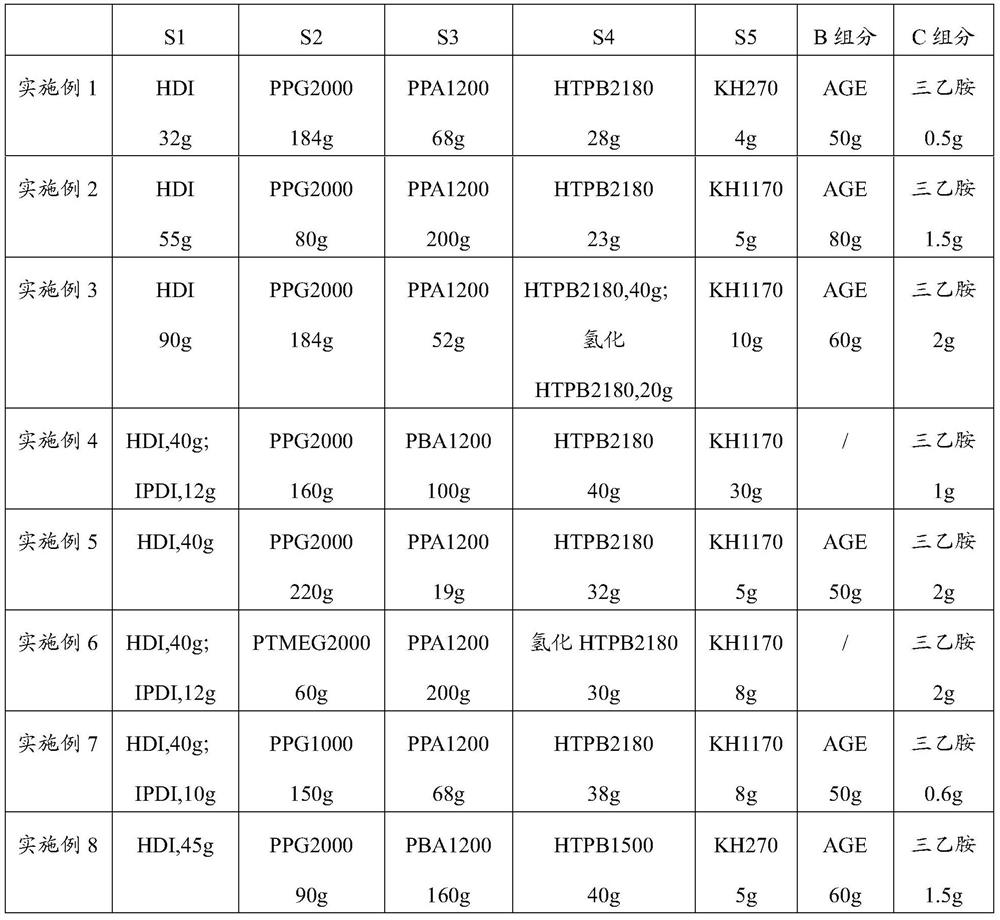

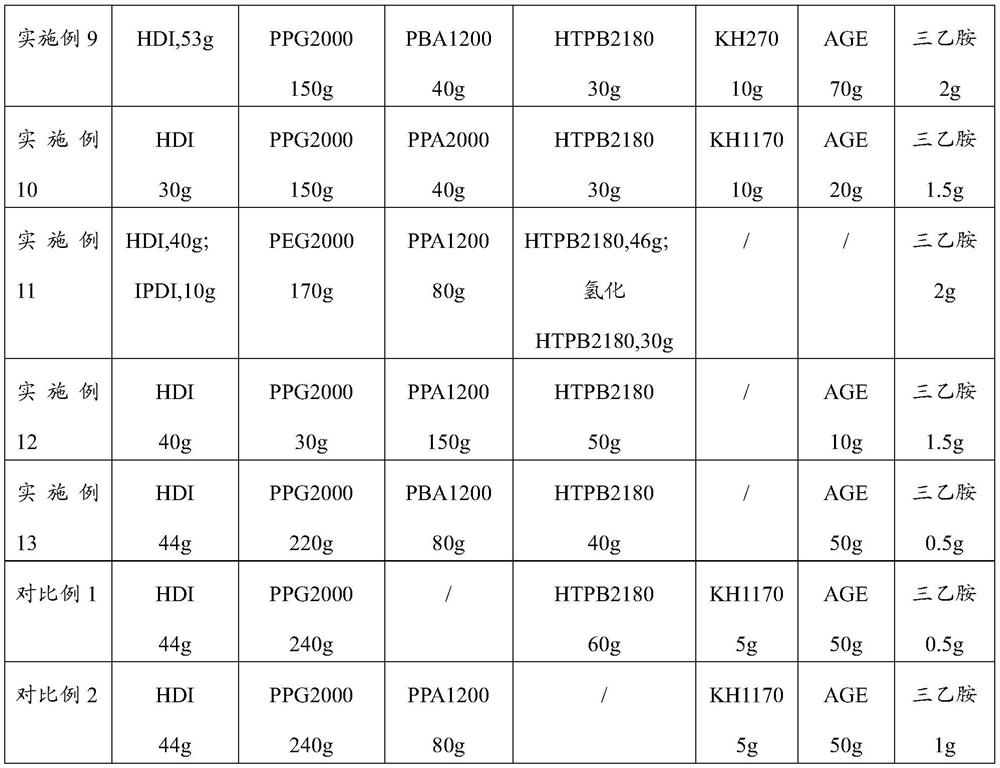

[0093] Embodiment 1-13 (namely S1-13) and comparative example 1-2 (namely D1-2)

Embodiment 1

[0095] 32g HDI (S1), 184g PPG2000 (S2), 68g PPA1200 (S3), 28g HTPB (S4), 0.1g 8108 catalyst through dehydration treatment were added to the 1L four-neck round bottom flask equipped with nitrogen inlet and outlet, The mixture was stirred at 80°C (denoted as reaction temperature 1) until the NCO reached the theoretical value (denoted as NCO theoretical value a) of 1.00%. The temperature was lowered to 50°C (referred to as reaction temperature 2), 4 g of KH270 (S5) was added, and the reaction was continued with stirring until NCO reached a new theoretical value (referred to as NCO theoretical value b) 0.65%. Add 0.5g triethylamine (component C) to the system, stir evenly to obtain adhesive a; test the viscosity of the adhesive a to be 11200cp; then add 50g AGE (component B) to the adhesive a system to carry out Stir and dilute to obtain adhesive b, and its viscosity is tested to be 8000cP; the adhesive b is sealed and stored.

[0096] Embodiment 2-13 and comparative example 1-2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com