Processing process for small crescent block of inner meshing gear pump

An internal gear pump and processing technology, applied in the field of hydraulic pump manufacturing, can solve the problems of low precision of parts, slow wire cutting processing speed, poor surface roughness, etc., to improve the yield rate, good compactness and increase wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

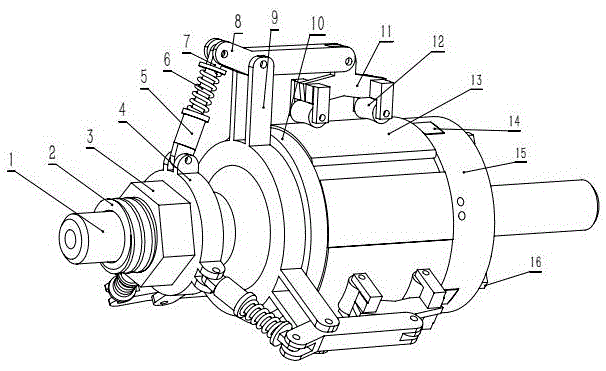

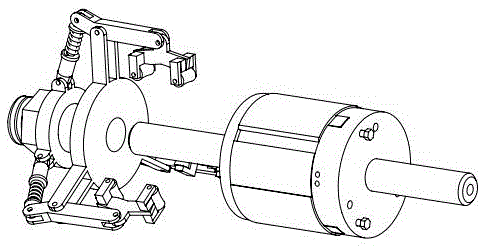

Image

Examples

Embodiment 1

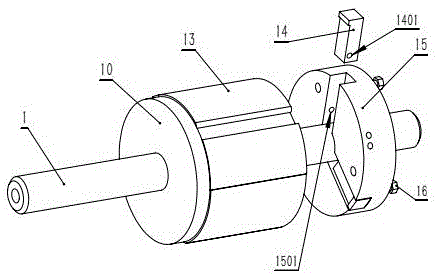

[0025] A small crescent block processing technology for internal gear pumps, taking a small crescent block with an outer diameter of 80mm, an inner diameter of 70mm, and a width of 50mm as an example, it is produced according to the following steps:

[0026] 1. Use the hot extrusion process to make long strips of small crescent block profiles: first design and manufacture the mold according to the section of the small crescent block, and use the extruder to extrude the heated round casting rod from the mold;

[0027] 2. Cut the strip-shaped small crescent block profile into a semicircular sheet-shaped small crescent block according to a certain length;

[0028] 3. Put the semicircular sheet-shaped small crescent block 13 into the end face grinding fixture and grind one end face on a surface grinder. After grinding, turn the product into a clamp and grind the other end face;

[0029] 4. Put the product into the jig for grinding the outer circle and clamp it, then roughly grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com