Low-cost anisotropic sintered permanent magnetic ferrite radial multi-pole magnetic ring forming mould and method

A permanent magnet ferrite, anisotropic technology, applied in the direction of permanent magnet manufacturing, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of no involvement, reduce material waste, improve product qualification rate, and improve grinding efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

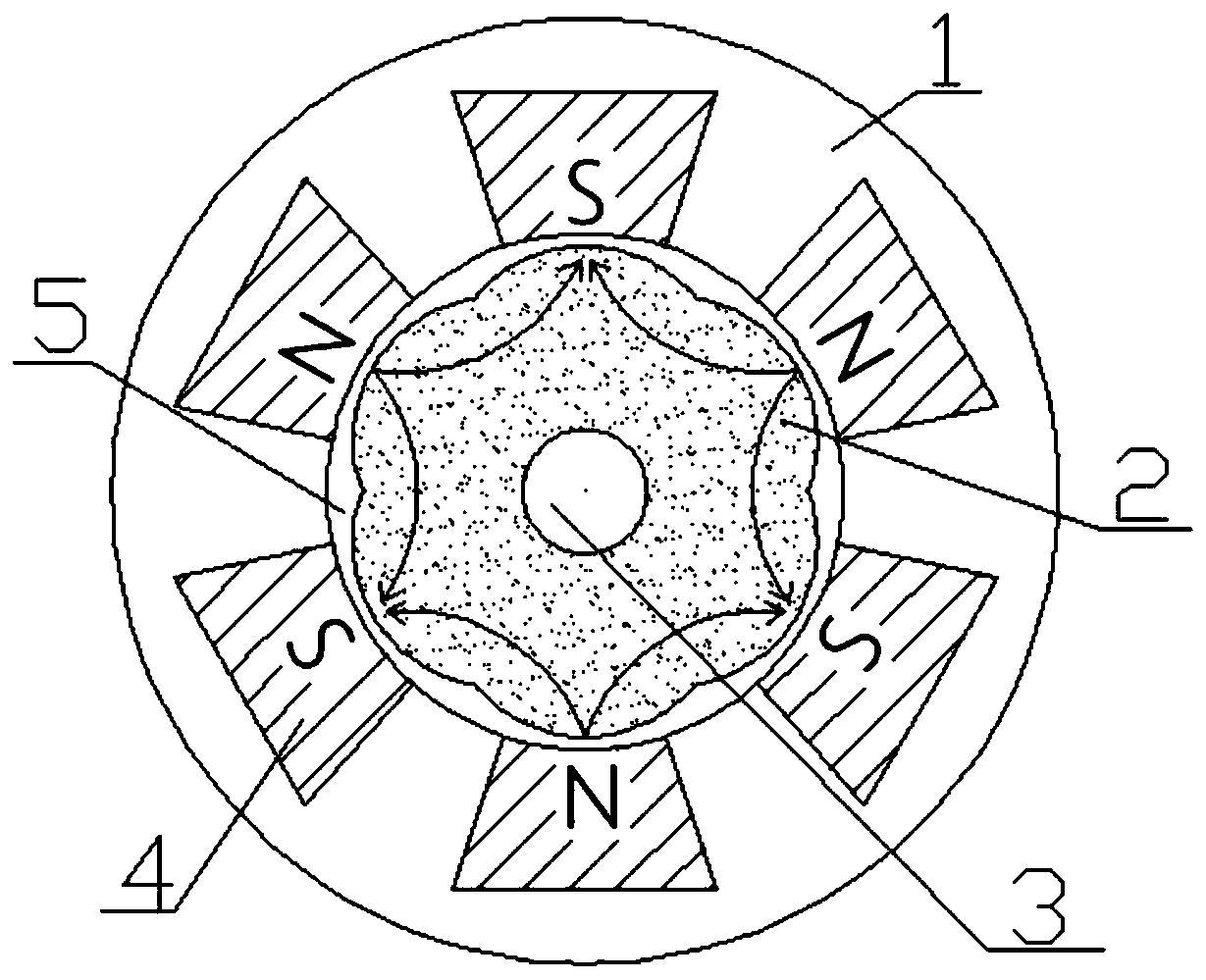

[0032] Example 1: Taking the preparation of an anisotropic sintered permanent ferrite radially oriented hexapole magnetic ring as an example, as figure 1 As shown, the forming mold mainly includes a yoke 1, a ferrite magnetic powder 2, a core rod 3, an NdFeB magnetic block 4, and a mold wall 5. The inner side of the mold wall 5 is used to fill the ferrite magnetic powder 2, and the core rod 3 is set At the center of the inner side of the mold wall, a number of NdFeB magnetic blocks 4 are evenly distributed on the outer circumference of the mold wall 5, and the magnetic poles of two adjacent NdFeB magnetic blocks 4 are set to opposite sexes, and a yoke 1 is set outside the NdFeB magnetic block 4 .

[0033] The number of said NdFeB magnetic blocks 4 is six.

[0034] Adopt the method for above-mentioned forming mold, comprise the following steps:

[0035] 1) Preparation of powder: Take a certain amount of ferrite magnetic powder to prepare the main raw material according to the...

Embodiment 2

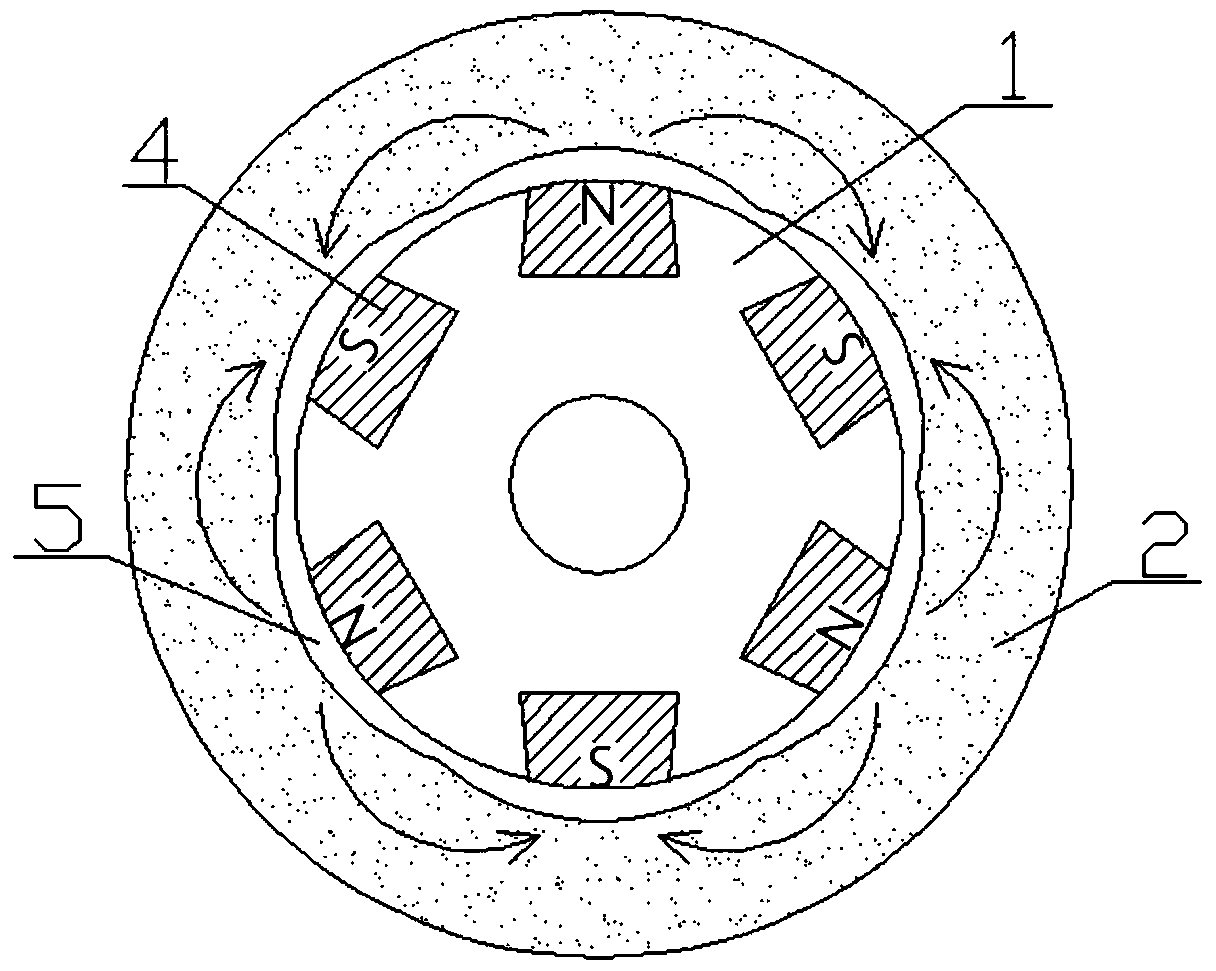

[0041] Example 2: Taking the preparation of an anisotropic sintered permanent ferrite radially oriented hexapole magnetic ring as an example, as figure 2 As shown, the forming mold mainly includes a yoke 1, ferrite magnetic powder 2, NdFeB magnetic block 4, and mold wall 5. The outer side of the mold wall 5 is used to fill the ferrite magnetic powder 2, and the inner circumference of the mold wall 5 is evenly distributed. NdFeB magnetic blocks 4, and the magnetic poles of two adjacent NdFeB magnetic blocks 4 are set to opposite sexes, and the inner side of the NdFeB magnetic blocks 4 is provided with a yoke 1.

[0042] The number of said NdFeB magnetic blocks 4 is six.

[0043] Adopt the method for above-mentioned forming mold, comprise the following steps:

[0044] 1) Preparation of powder: Take a certain amount of ferrite magnetic powder to prepare the main raw material according to the predetermined formula, add additives once to wet-mill the mixture, and pre-sinter the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com