High-efficiency unequal multi-blade expanding reamer

A reamer and equal division technology, applied in the direction of reamers, reaming devices, metal processing equipment, etc., can solve the problems of reducing tool vibration, blocking holes, etc., to reduce tool vibration, reduce resonance, improve machining allowance and cutting. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

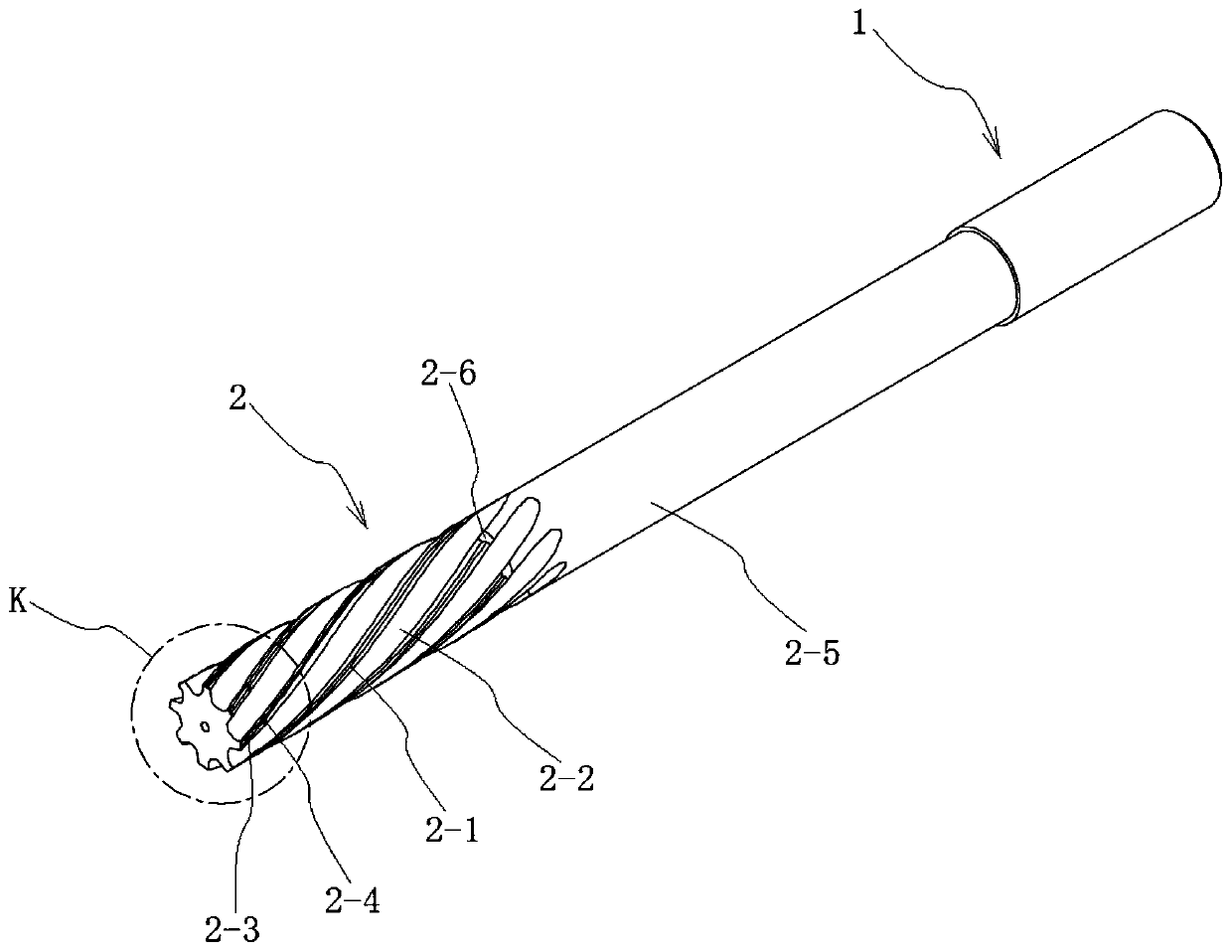

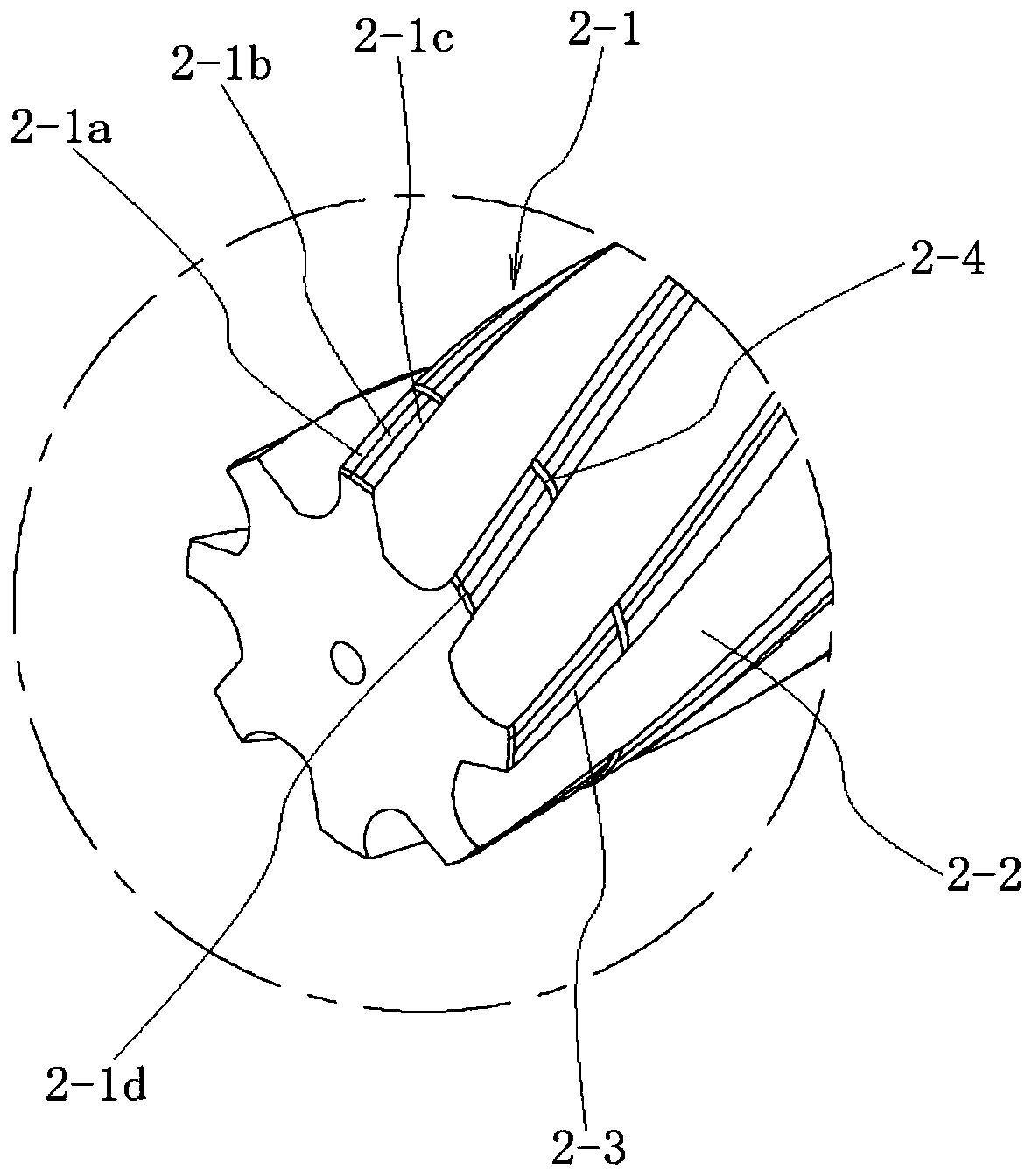

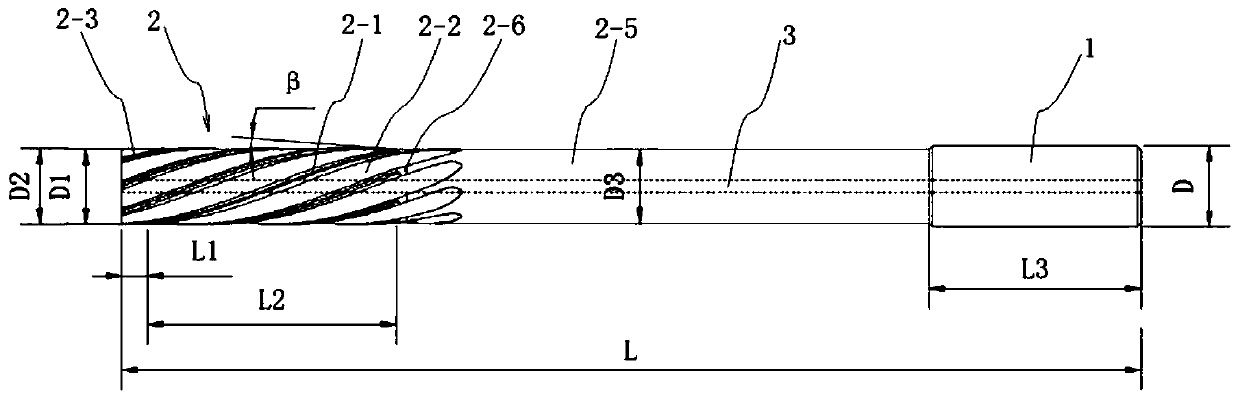

[0046] This embodiment takes an eight-blade expanding reamer as an example to further illustrate the design principle of a high-efficiency unequal multi-blade expanding reamer of the present invention. see figure 1 , figure 2 , Figure 4 and Figure 5 As shown, the eight-edged reamer of this embodiment adopts a left-handed right-cut structure, which includes a handle 1 and a cutting part 2 located at the front of the handle 1, and the cutting part 2 has eight helical cutting edges distributed in the circumferential direction. 2-1, there is a spiral groove 2-2 for chip holding and chip removal between two adjacent cutting edges 2-1, and the cutting edge 2-1 of the eight-edged reamer has unequal parts in the circumferential direction structure, the design principle of the unequal structure is: on the cross section of the cutting part 2, the difference between the maximum and minimum pitch angles between two adjacent cutting edges 2-1 is 6° to 9°, Further, at least one pair ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com