Shaping method for drum of drying machine and rolled drum structure according to it

A molding method and dryer technology, applied in household dryers, applications, household appliances, etc., can solve the problems of increasing vibration and noise, complicated manufacturing process, affecting product reliability, etc., to reduce vibration and noise, improve The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

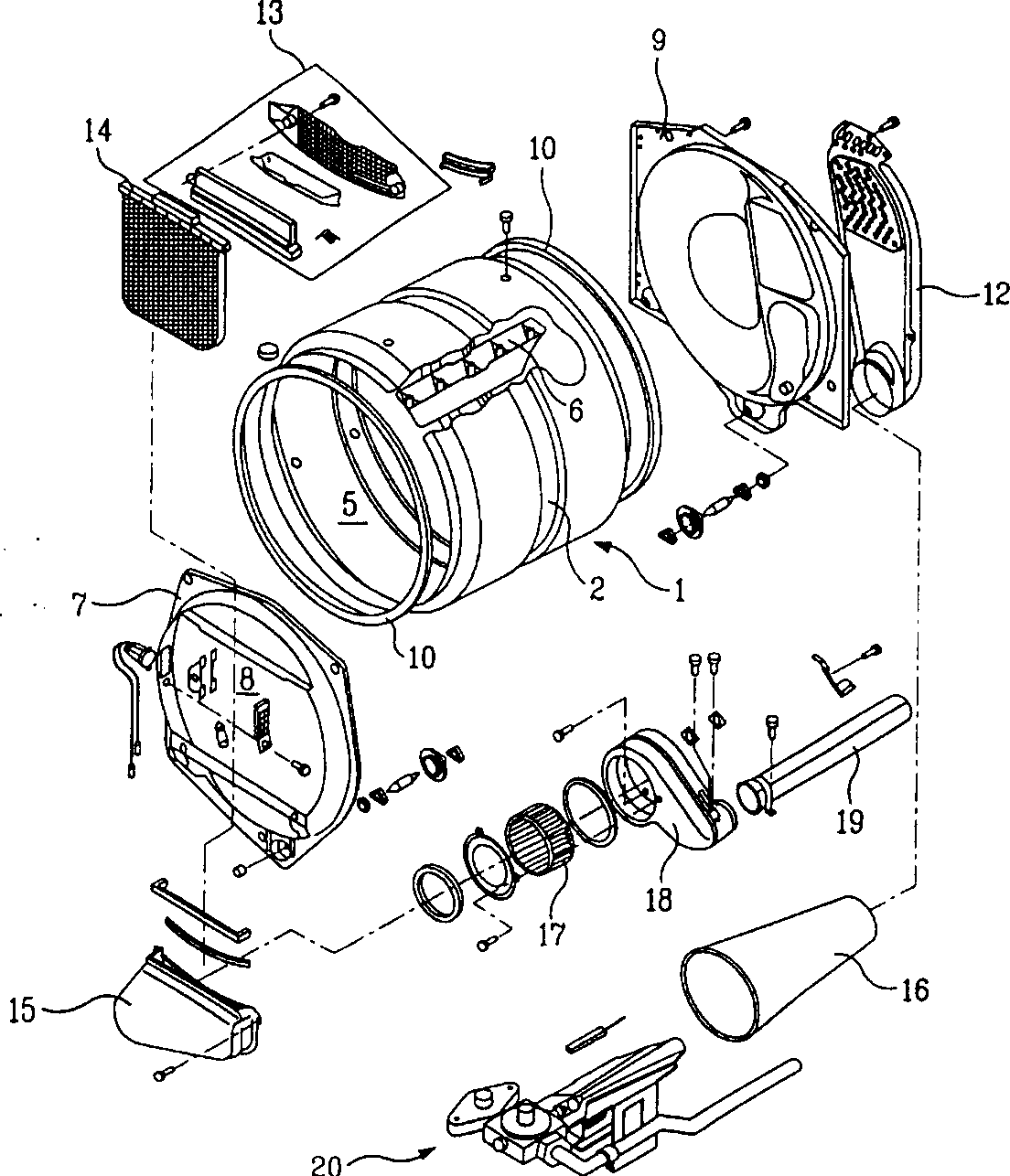

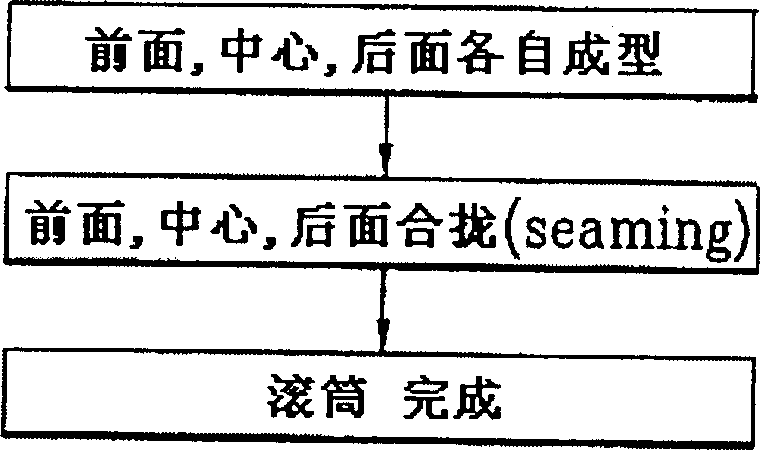

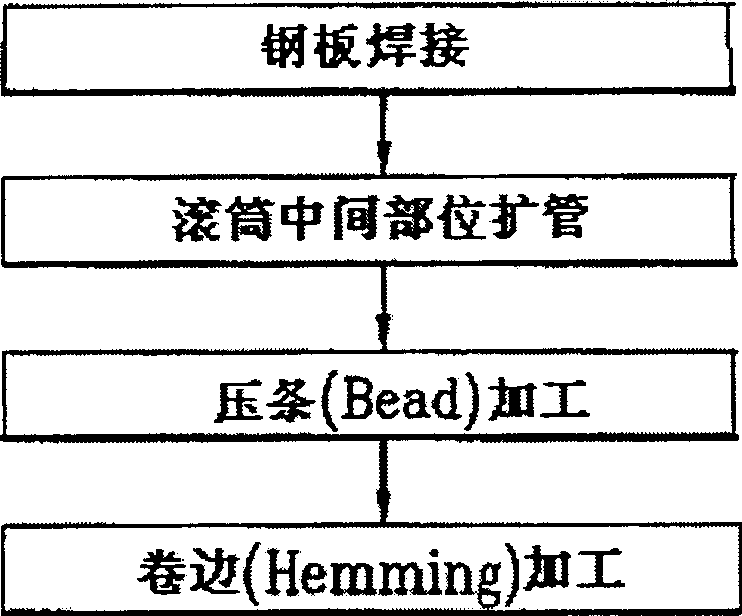

[0058] image 3 It is a flow chart of the drum forming process of the present invention, Figure 4 is according to image 3 A diagram of the forming process showing the state of the drum. The drum molding process for dryer of the present invention can be roughly divided into the stage of cylindrical drum (1) molding, the stage of tube expansion molding except the two ends of cylindrical drum (1), the cylindrical drum (1) The stage of processing the bead (1b) on the expanding part (1a) of the drum, and the stage of crimping in order to stack the outer peripheries of both sides of the drum.

[0059] The forming stage of the cylindrical drum (1) is: first roll metal steel plates of materials such as stainless steel into a cylindrical shape, and then we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com