Clutch assistor for car

A clutch and booster technology, applied in clutches, mechanical equipment and other directions, can solve the problems of high manufacturing cost, low qualification rate, affecting the sealing of booster piston, etc., and achieve the effect of low manufacturing cost, high qualification rate and avoiding strain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

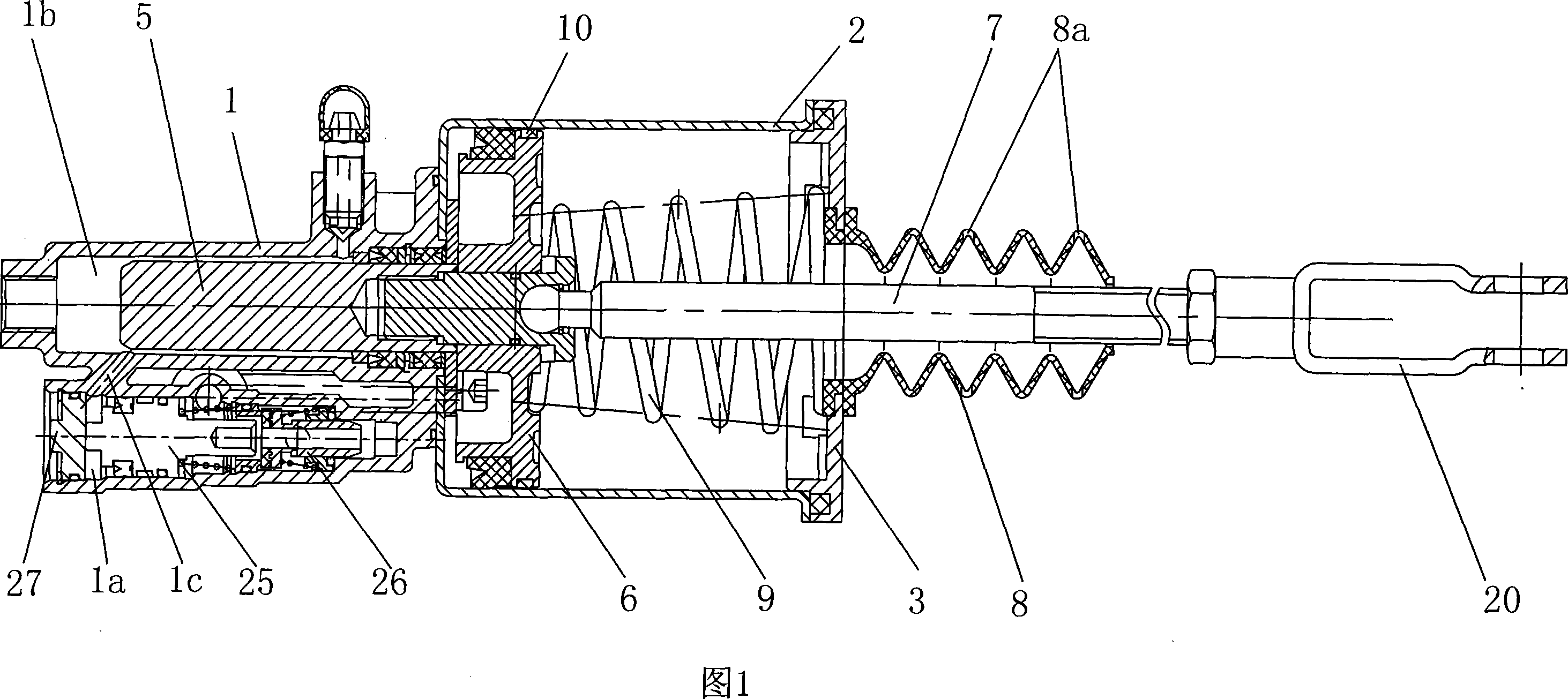

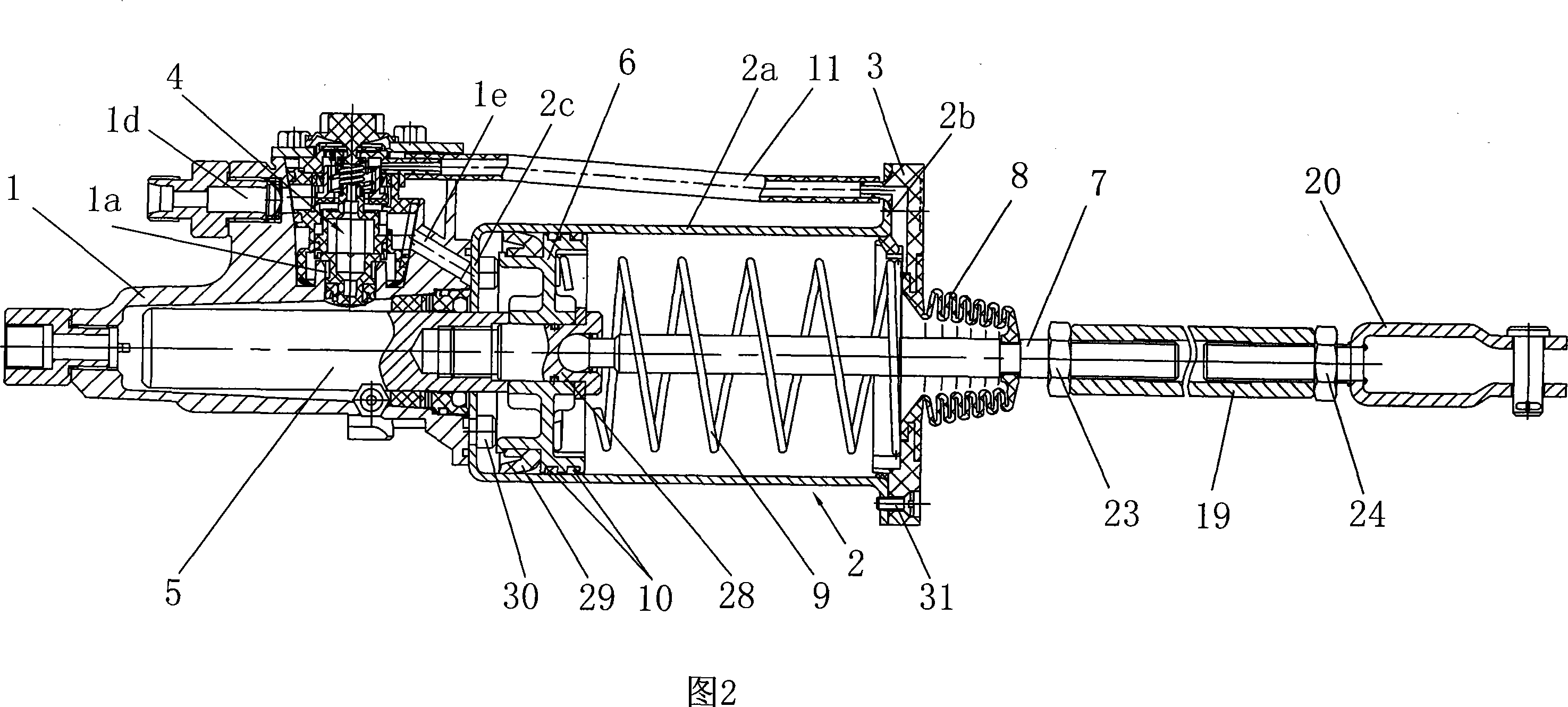

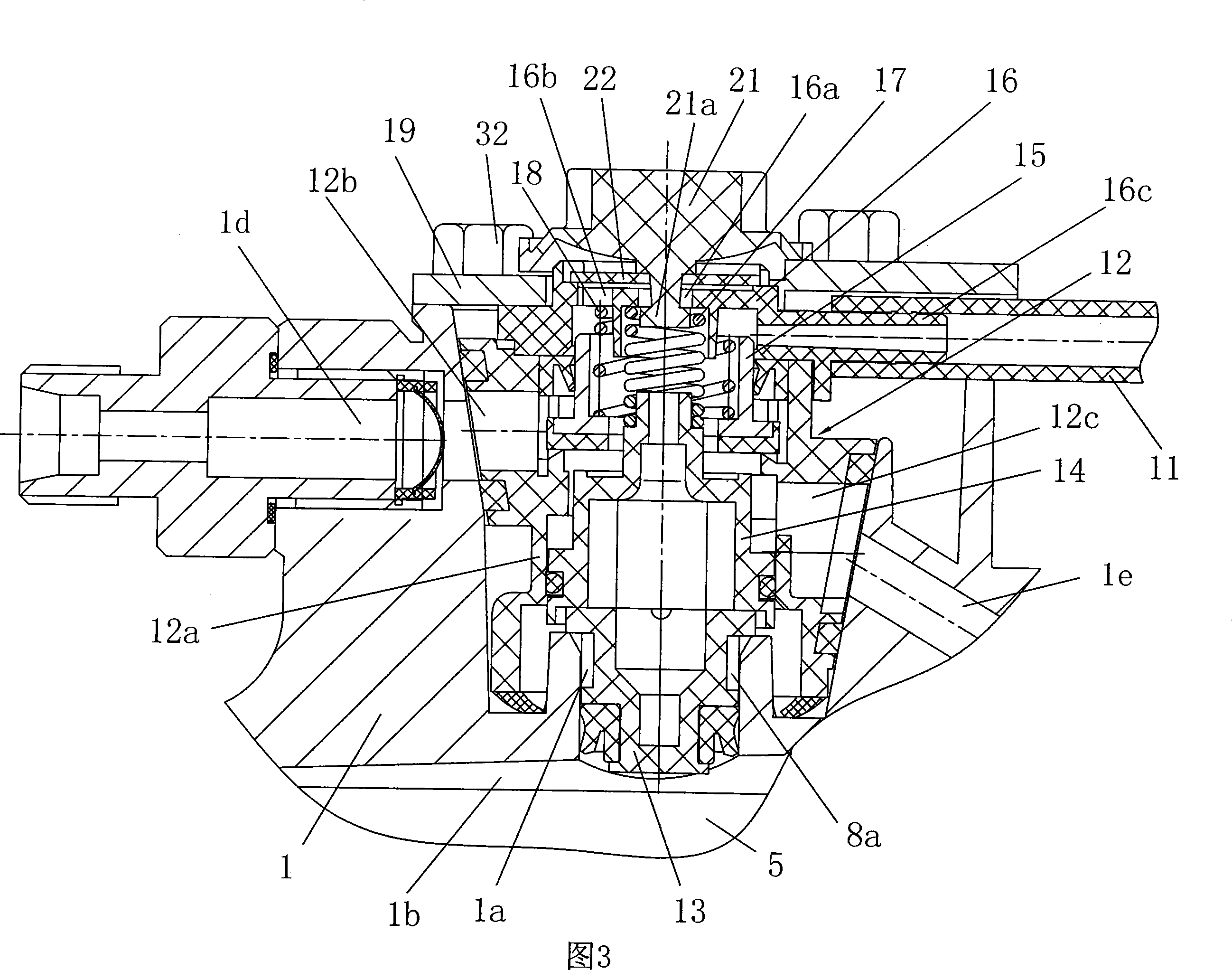

[0023] As shown in Figure 2, the present invention mainly consists of a cylinder shell 1, a cylinder 2, a flange 3, an air valve assembly 4, a cylinder piston 5, a booster piston 6, a push rod 7, a dust cover 8, a main spring 9, a damper Friction ring 10, air pipe 11, adjusting screw sleeve 19, separating fork 20, right-handed nut 23 and left-handed nut 24 form. Wherein the sealing end of cylinder shell 1 and cylinder 2 is fixed by bolt 30, and the front end of cylinder 2, that is, the open end, is connected with flange 3 by screw 31, and cylinder piston 5 is housed in cylinder 1b of cylinder shell 1, and the cylinder piston 5 One end extends into the cylinder 2 and is threadedly connected with the booster piston 6 through the connecting sleeve 28. A push rod 7 is fixed at the center of the front end of the booster piston 6, and the other end of the push rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com