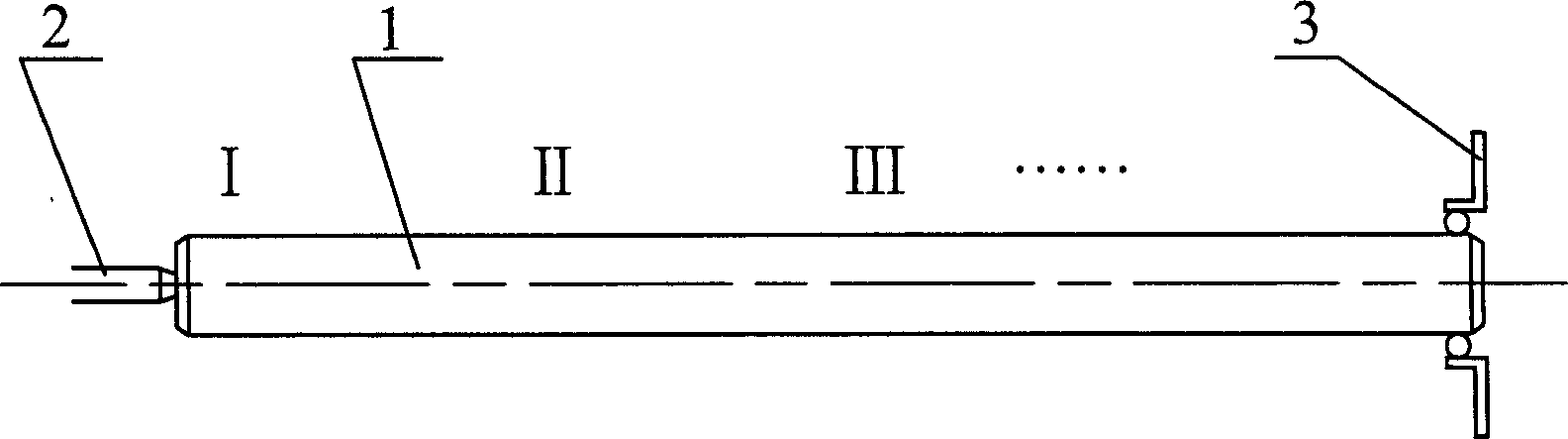

Marine stern axle tube boring technological equipment erecting process

A stern tube and process technology, which is applied in the field of ship stern tube boring tooling and erection technology, can solve the problems of large coaxiality of the stern tube fore and aft inner holes, affecting the assembly quality of the stern shaft, etc., so as to shorten the construction period, reduce the surface The effect of improving roughness and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

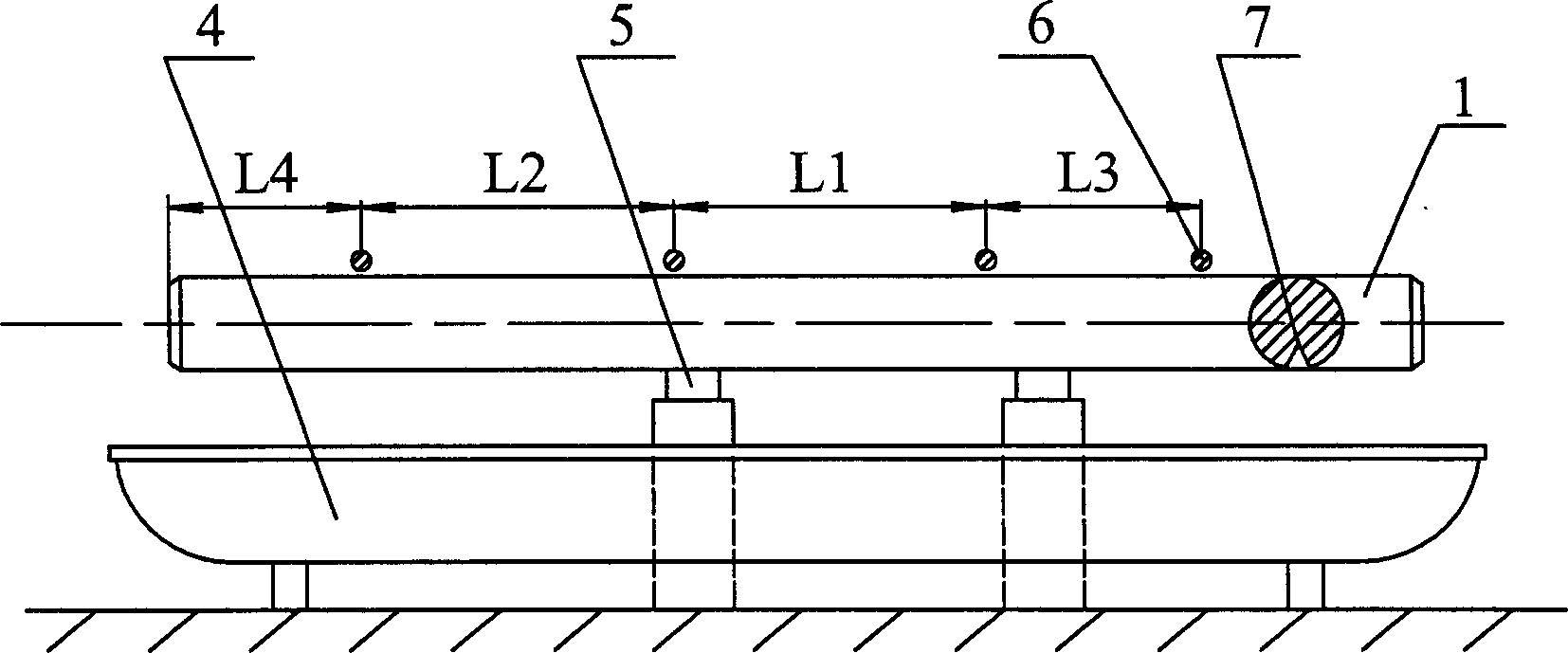

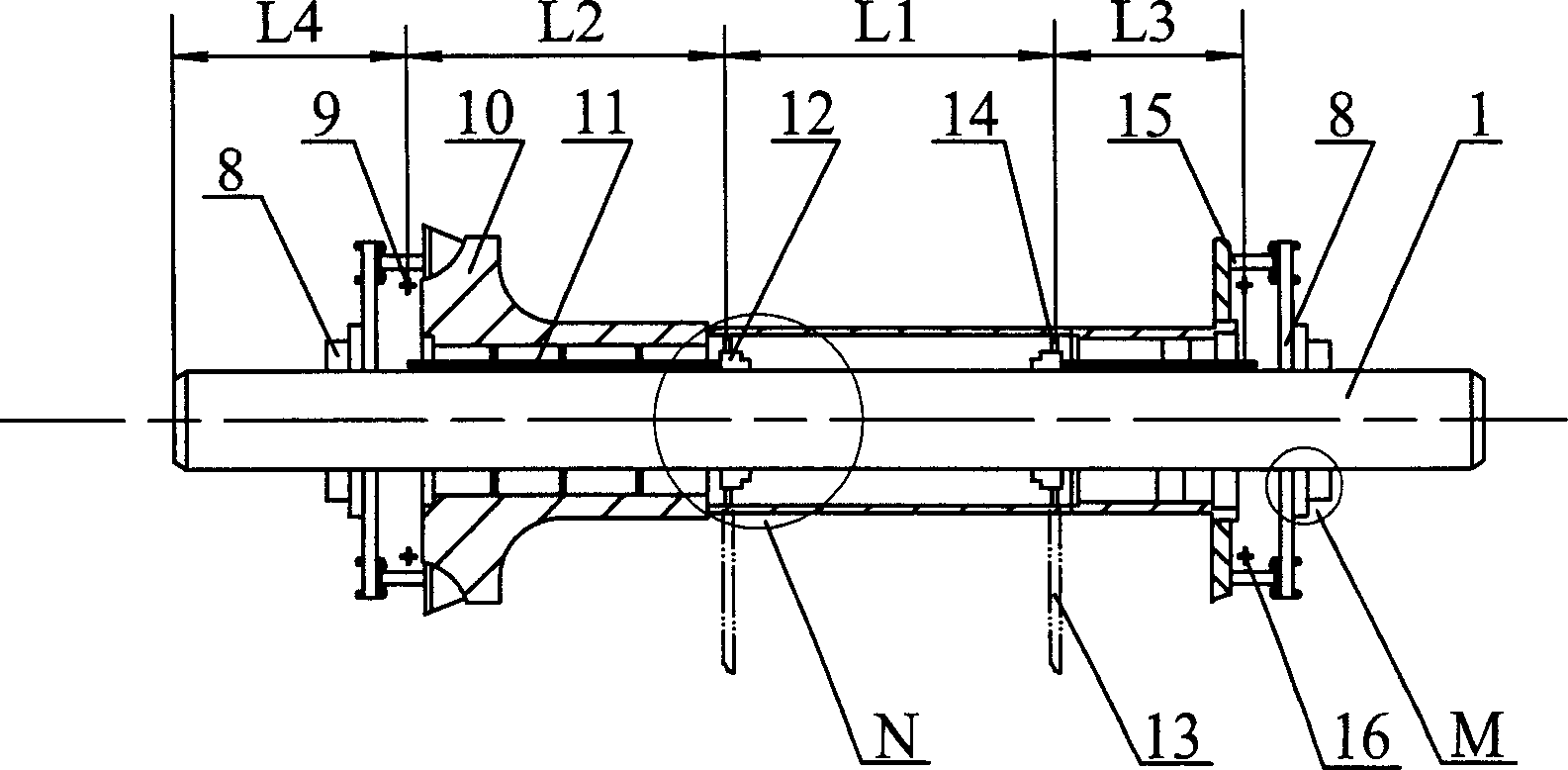

[0020] The present invention is to complete the boring process of the inner holes of the bearing hubs of the ship shafting system. In order to ensure the coaxiality of the axes of the bearing hubs, the boring bar must have good straightness, because the ratio of the diameter to the length of the boring bar is generally Between 1:25-1:40, it belongs to the slender rod structure, it is difficult to ensure the straightness of the axis of the boring bar with two support points, so a support point should be added in the middle of the boring bar. The special intermediate support can be adjusted externally by the operator without opening the process hole in the stern tube, so as to eliminate the deflection of the boring bar and make the axis of the boring bar coincide with the axis of the hull.

[0021] The erection process of ship stern tube boring tooling, the process steps are as follows:

[0022] 1. For the determination of the position of the intermediate support in the stern tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com