Rotor of resultant magnetic field

A technology for synthesizing magnetic fields and rotors, applied in the fields of machinery manufacturing and motors, can solve the problems of increasing the magnetic pole magnetic density of the motor and the utilization rate of magnetic materials is not improved, and achieve the effects of improving the magnetic density, small rotor diameter, and high cylindricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

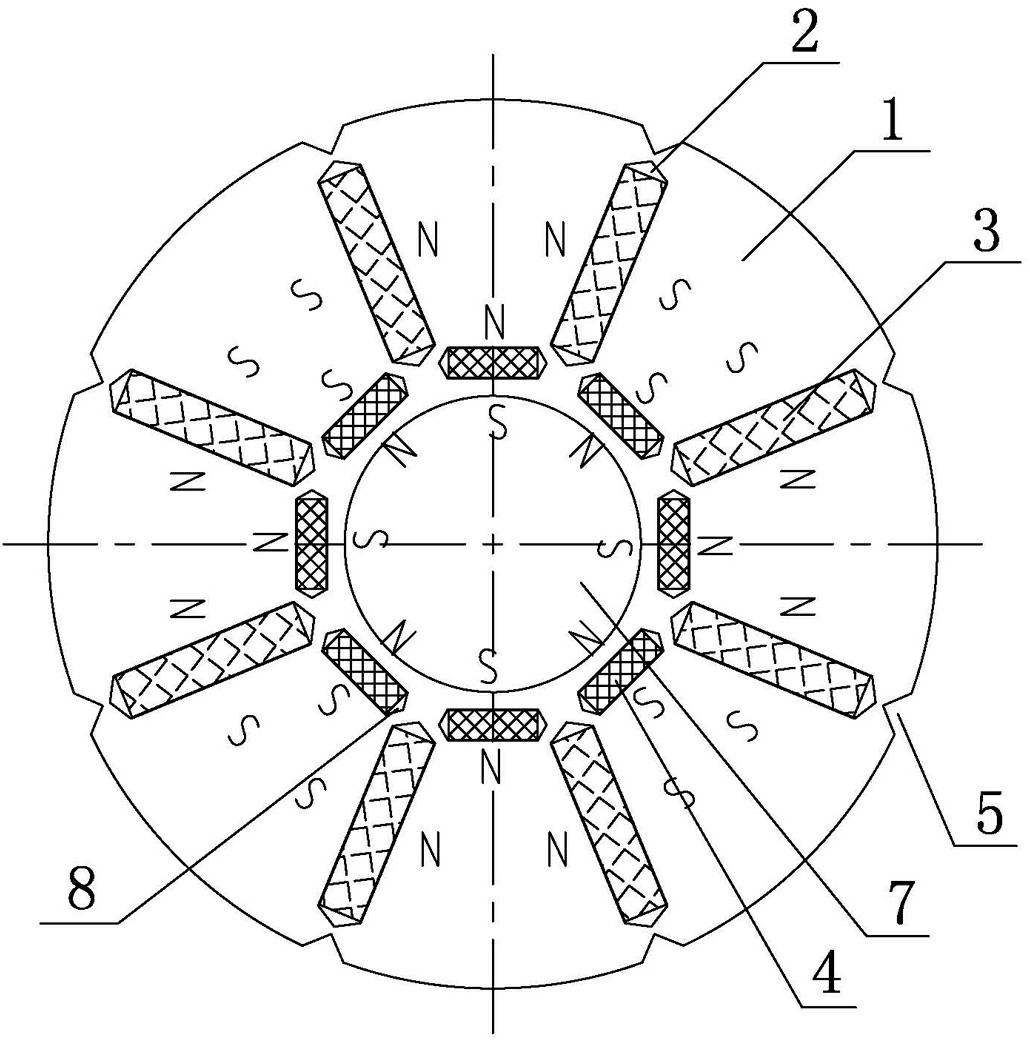

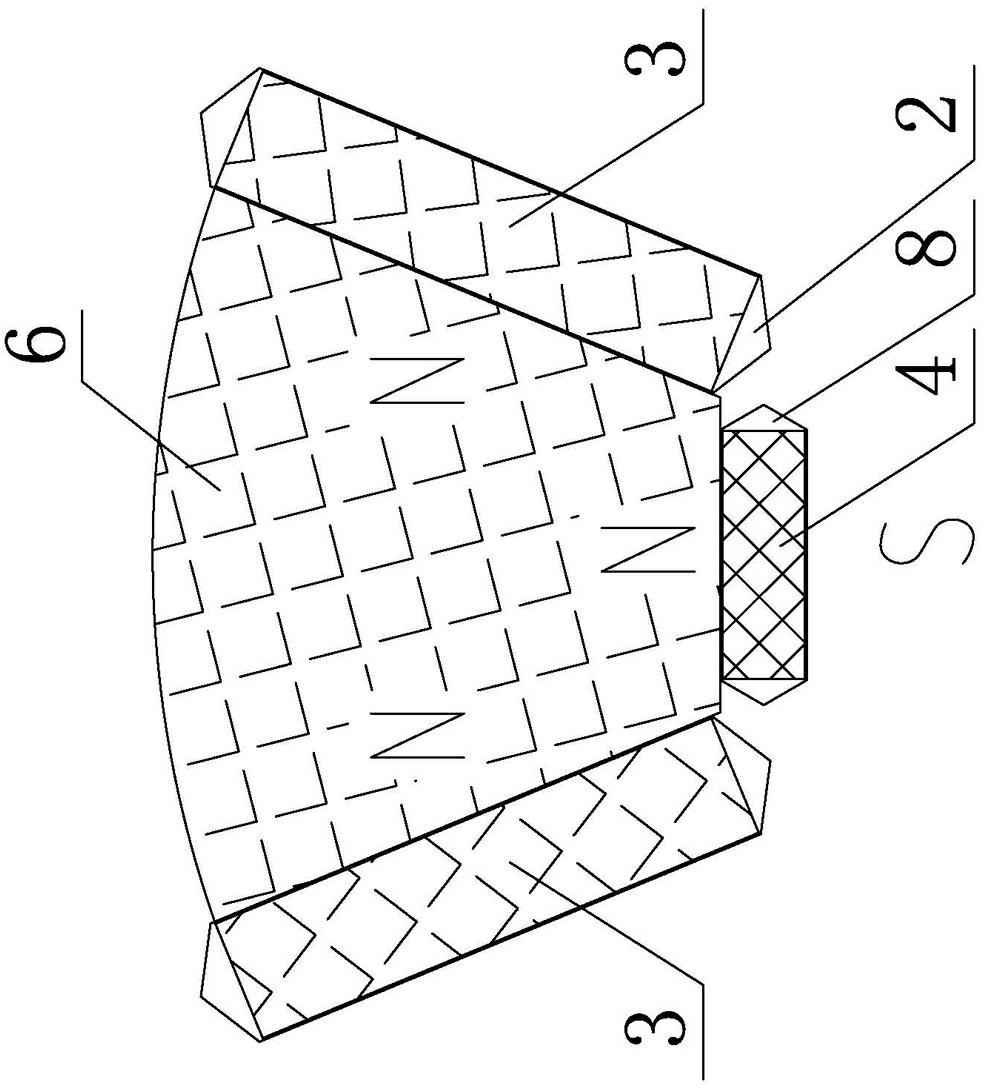

[0023] Embodiment 1: as Figure 1-Figure 4 As shown, this embodiment includes a coaxially arranged rotor core 1 (silicon steel sheet) and a rotor shaft 7, wherein the rotor core 1 is evenly punched with eight main magnetic steel mounting holes 2 in the radial direction, and the holes are embedded with There are main magnets 3 with a rectangular cross-section. After installation, each main magnet 3 is in the shape of a spoke with the axis of the rotor shaft 7 as the center, and is arranged radially opposite each other, that is, each main magnet 3 is arranged along the rotor core 1 diameter Arranged evenly in the direction; A secondary magnetic steel mounting hole 8 is punched between two adjacent main magnetic steel mounting holes 2, close to the inner diameter of the rotor core 1, and a secondary magnetic steel 4 with a rectangular cross section is embedded in the hole. In order to reduce magnetic flux leakage; after the installation is completed, each auxiliary magnet 4 is ar...

Embodiment 2

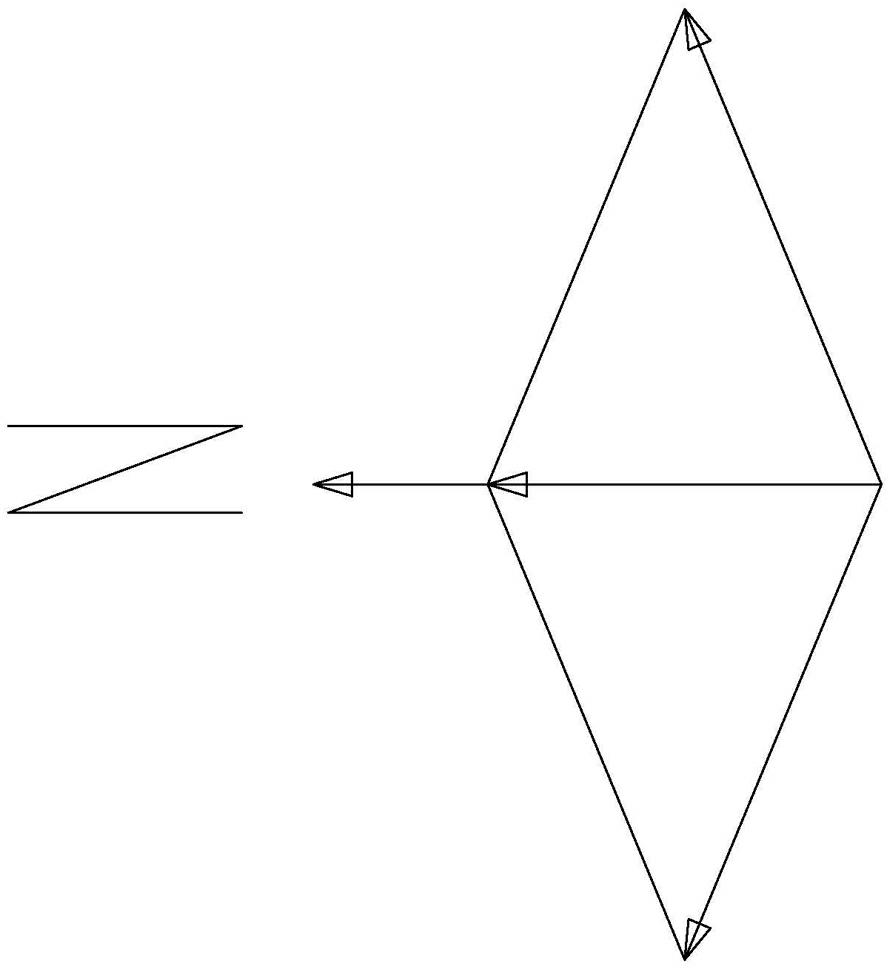

[0027] Embodiment 2: as Figure 5-Figure 7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the secondary magnetic steel installation hole 8 and the secondary magnetic steel 4 are removed, and at the same time, there are punched on the rotor core 1 between two adjacent main magnetic steels 3 The slots 9 with an isosceles triangle cross section, that is, the slots 9 are evenly arranged radially along the rotor core 1, and their length is roughly the same as that of the main magnetic steel 3, and the bottom of the slots is close to the rotor core 1 Inner diameter, and parallel to the tangent arrangement of the circumferential surface of the rotor shaft 7, the symmetry axes of the two adjacent main magnets 3 located on both sides of the slot coincide with the angle bisector of the top angle of the slot; the two adjacent main magnets 3 and a slot 9 located therebetween form two fan ring areas, and the iron cores in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com