Device and method for realizing axle hole assembly by utilizing flexibility of robot

A robotic and flexible technology, used in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of low positioning accuracy of fixtures, assembly failures, and restrictions on popularization and application, to eliminate position uncertainty, reduce positioning accuracy and The effect of the requirement of robot operation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

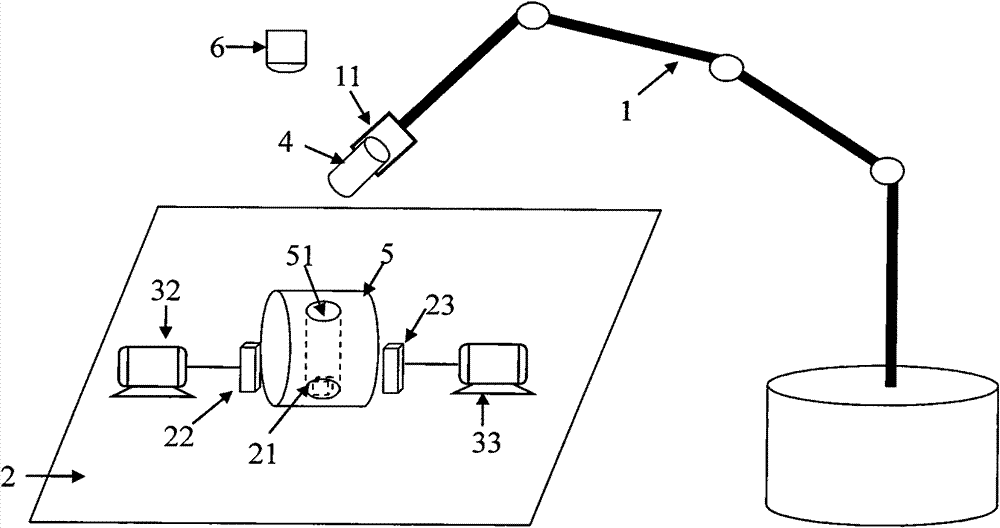

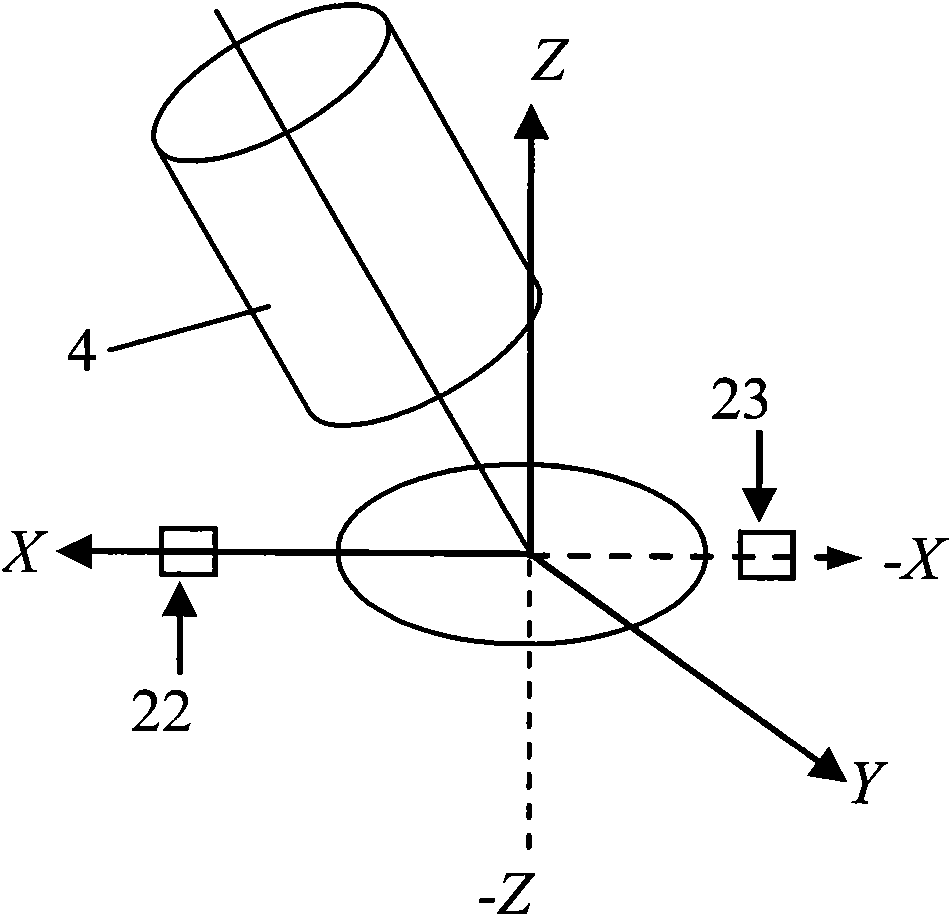

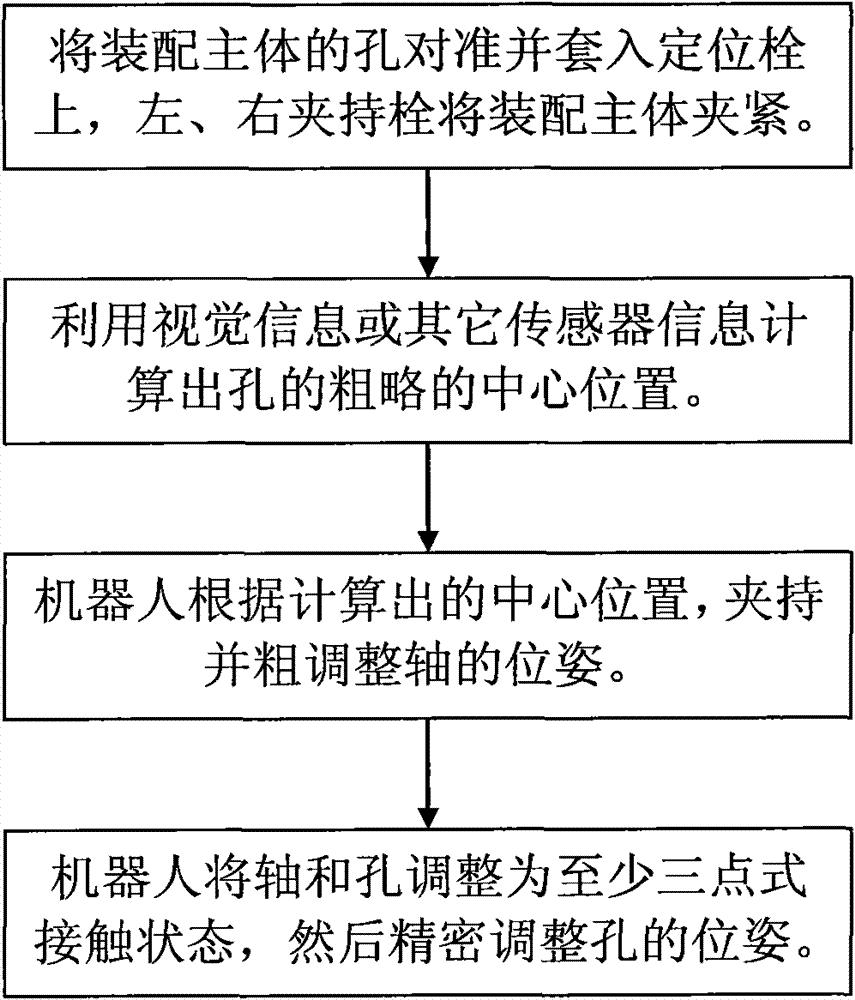

[0042] In order to make the purpose of the present invention, technical solutions and advantages clearer, now with the figure 1 The installation of the shaft 4 into the hole 51 on the cylindrical assembly body 5 shown in is a specific example, and the specific implementation manner of the present invention will be further described in detail.

[0043] Such as figure 1 As shown, at least two sets of clamping devices that can extend to the inside and retract to the outside are installed on the base 2, and the positioning bolt 21 is fixed on the position of the base 2 surrounded by all the clamping devices. Among all the clamping devices, The action points of at least one pair of clamping devices are on a straight line passing through and perpendicular to the center line of the positioning pin 21. Here, a pair of clamping devices satisfying this condition is defined as a pair of reference clamping devices, and the positioning pin 21 is defined as a pair of reference clamping devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com