Assembling device for filing shaft and toy gear

A technology for assembling devices and toys, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of low assembly efficiency and achieve high-precision assembly, high-precision and high-efficiency operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

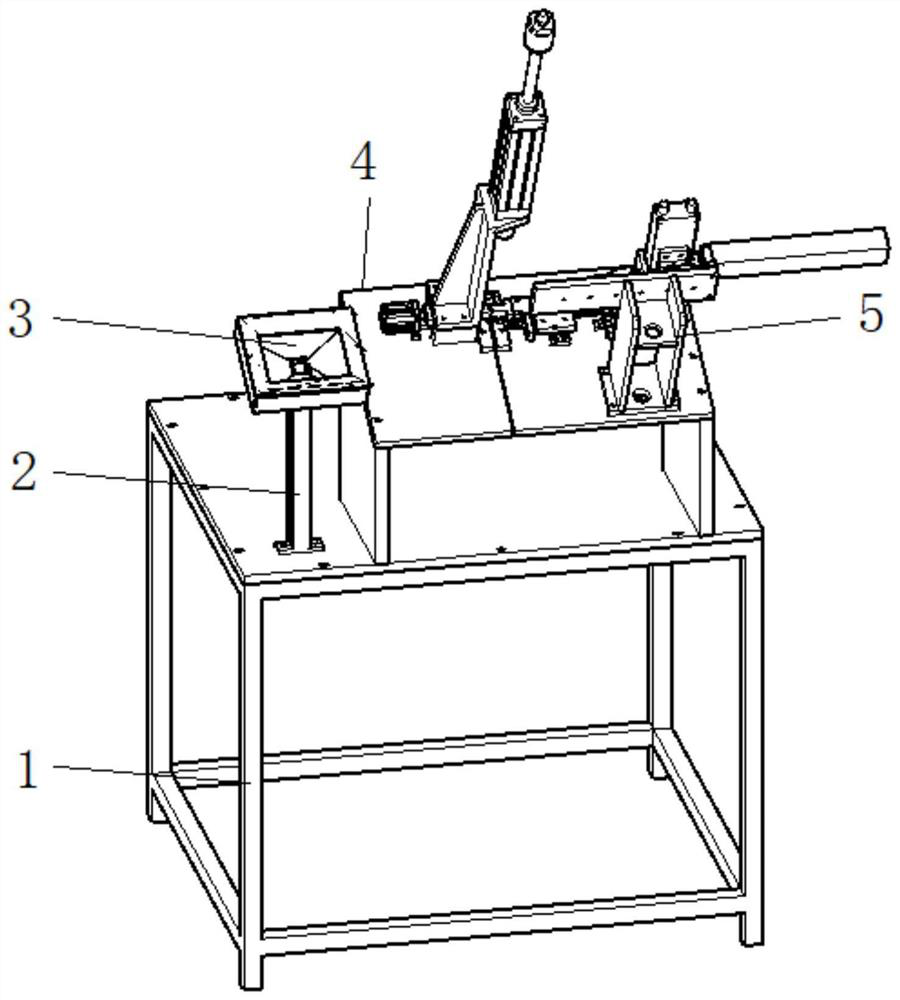

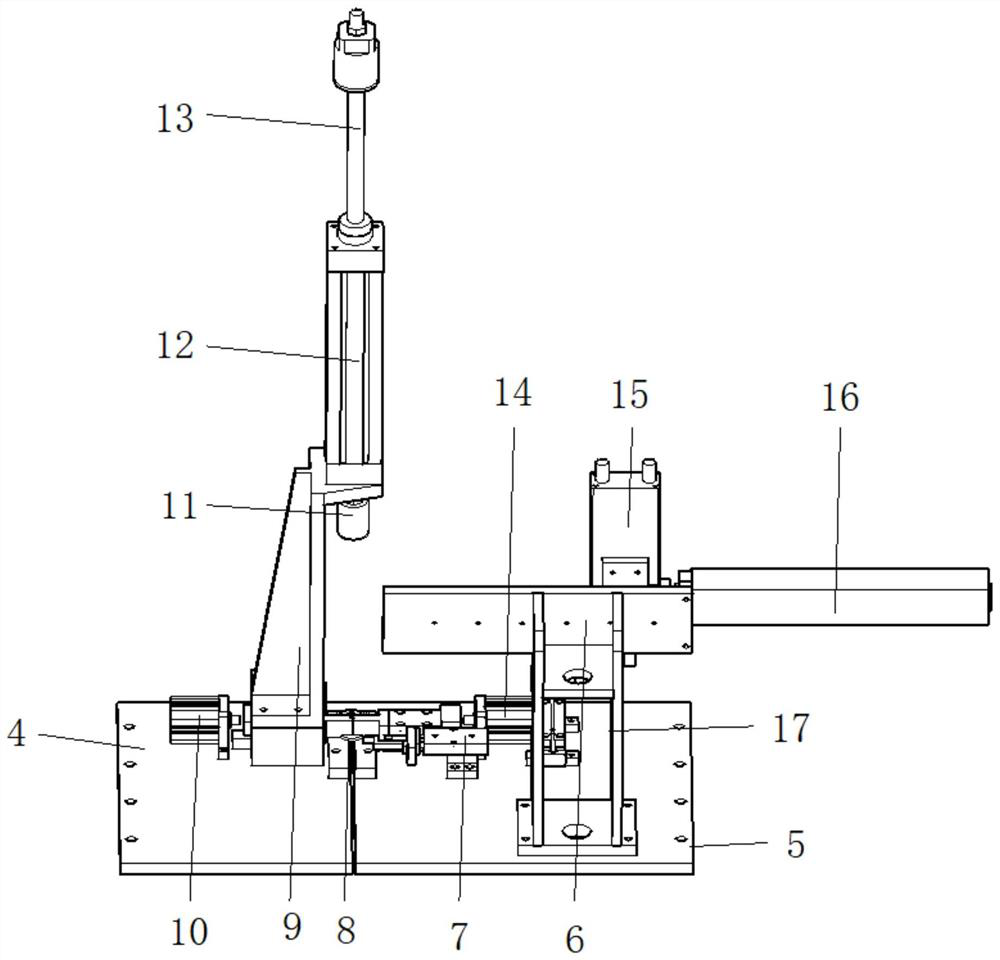

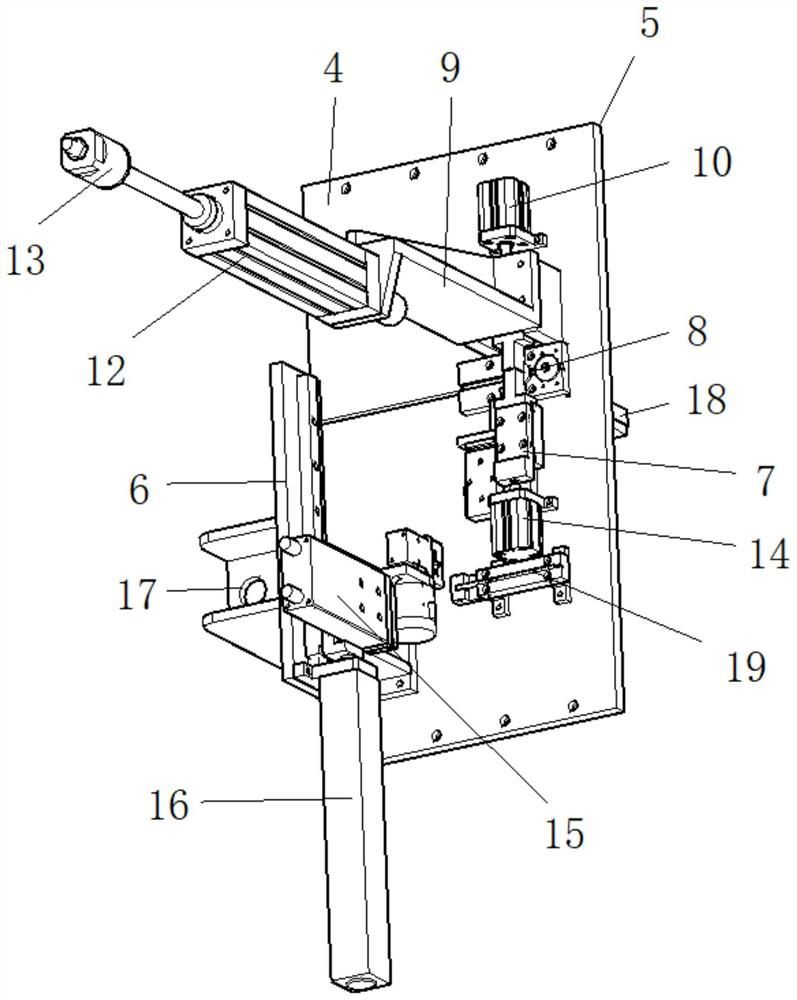

[0018] see Figure 1 to Figure 3 , the present invention provides a technical solution for an assembly device of a file shaft and a toy gear: a device for assembling a file shaft and a toy gear includes a machine 1 and an assembly mechanism 5, the assembly mechanism 5 is installed on the upper end surface of the machine 1, and the machine The upper end face bolt of platform 1 is fixed with support frame 2, and the top of support frame 2 is equipped with display screen 3, and display screen 3 is electrically connected with first motor 14, second motor 10, first cylinder 16 and second cylinder 12 respectively. Programming commands can be input through the display screen 3 , and the action control of the first motor 14 , the second motor 10 , the first cylinder 16 and the second cylinder 12 can be realized through the PLC controller built in the display screen 3 .

[0019] The assembly mechanism 5 includes a workbench 4, a second support 9 and a first support 17 are respectively ...

Embodiment 2

[0021] On the basis of Embodiment 1, the present invention further provides an embodiment of an assembly device for a file shaft and a toy gear: an assembly device for a file shaft and a toy gear, including a machine 1 and an assembly mechanism 5, and the assembly mechanism 5 is installed on The upper end surface of the machine platform 1, the upper end surface bolt of the machine platform 1 is fixed with a support frame 2, and the top of the support frame 2 is equipped with a display screen 3, and the display screen 3 is connected to the first motor 14, the second motor 10, and the first cylinder 16 respectively. It is electrically connected with the second cylinder 12. Programming commands can be input through the display screen 3 , and the action control of the first motor 14 , the second motor 10 , the first cylinder 16 and the second cylinder 12 can be realized through the PLC controller built in the display screen 3 .

[0022] The assembly mechanism 5 includes a workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com