clamping head

A clamping head and base technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to guarantee installation accuracy, easy to change, unfavorable high-precision assembly, etc., to prevent offset and strong adaptability The effect of high-precision, high-precision assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

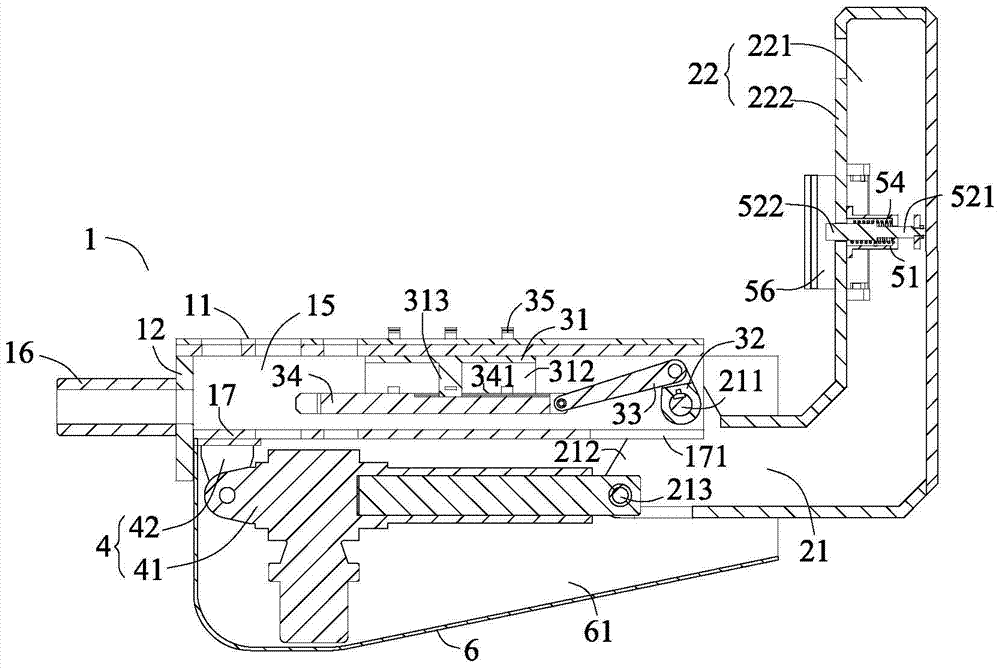

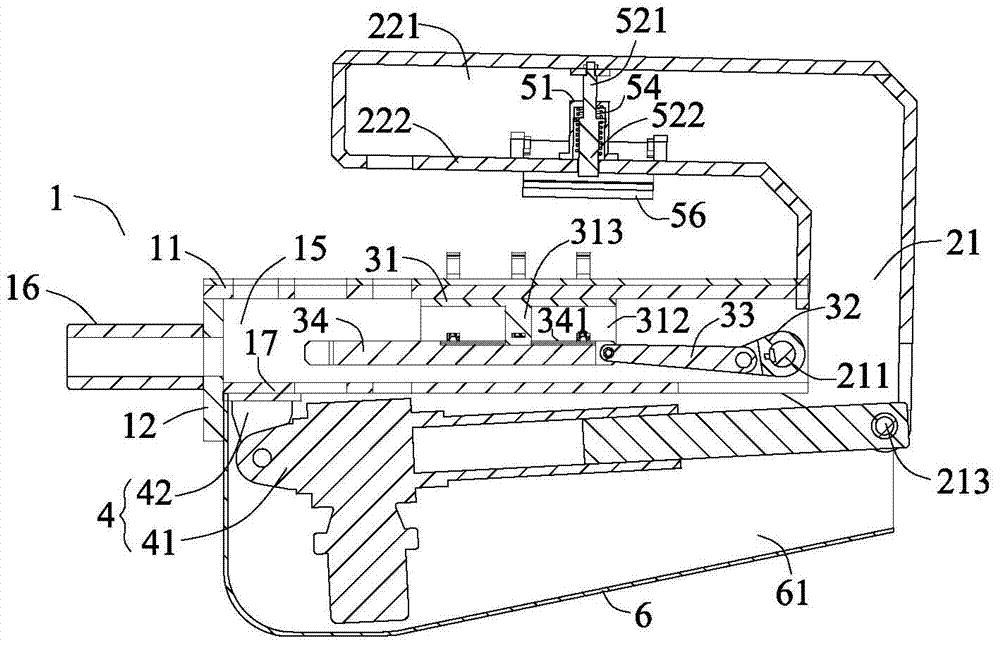

[0059] The clamping head of the present invention will be described in detail below with reference to the accompanying drawings.

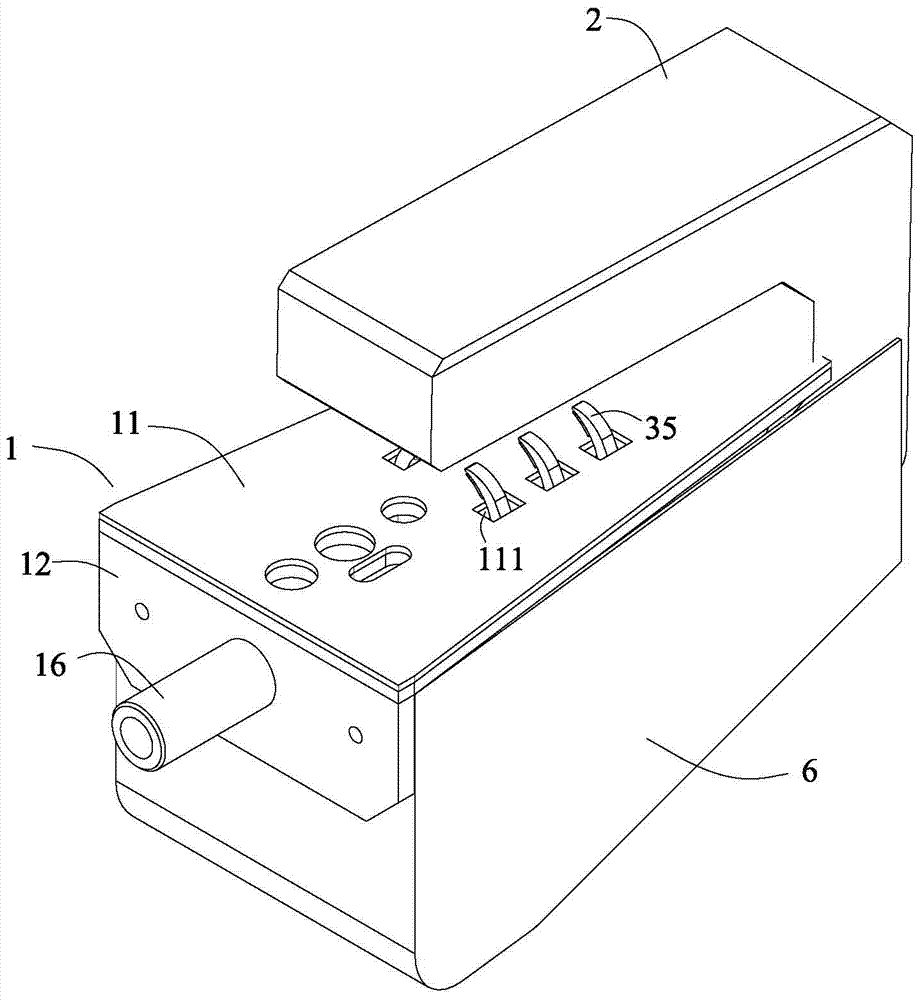

[0060] refer to Figure 1 to Figure 10 , The clamping head according to the present invention includes a base 1 , an overturn frame 2 , a finger fixing mechanism 3 , a driving mechanism 4 and a pressing block fixing mechanism 5 .

[0061] The base 1 is mounted on an external driving mechanism (not shown), and has: a top plate 11, provided with a plurality of first openings 111, arranged in two rows along the length direction; an end plate 12, connected to the front end of the top plate 11; and a left side plate 13 and the right side plate 14 are arranged on both sides of the end plate 12 and form a first cavity 15 with the top plate 11 and the end plate 12 .

[0062]The turning frame 2 has a connecting portion 21 and a turning portion 22 . The connecting part 21 has: a first rotating shaft 211, the two ends of which are pivotally connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com