Object lens and optical pickup device

A technology of optical pickup device and objective lens, which is applied in the direction of optics, condenser lens, optical elements, etc., and can solve problems such as the inability to measure the inclination of the objective lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

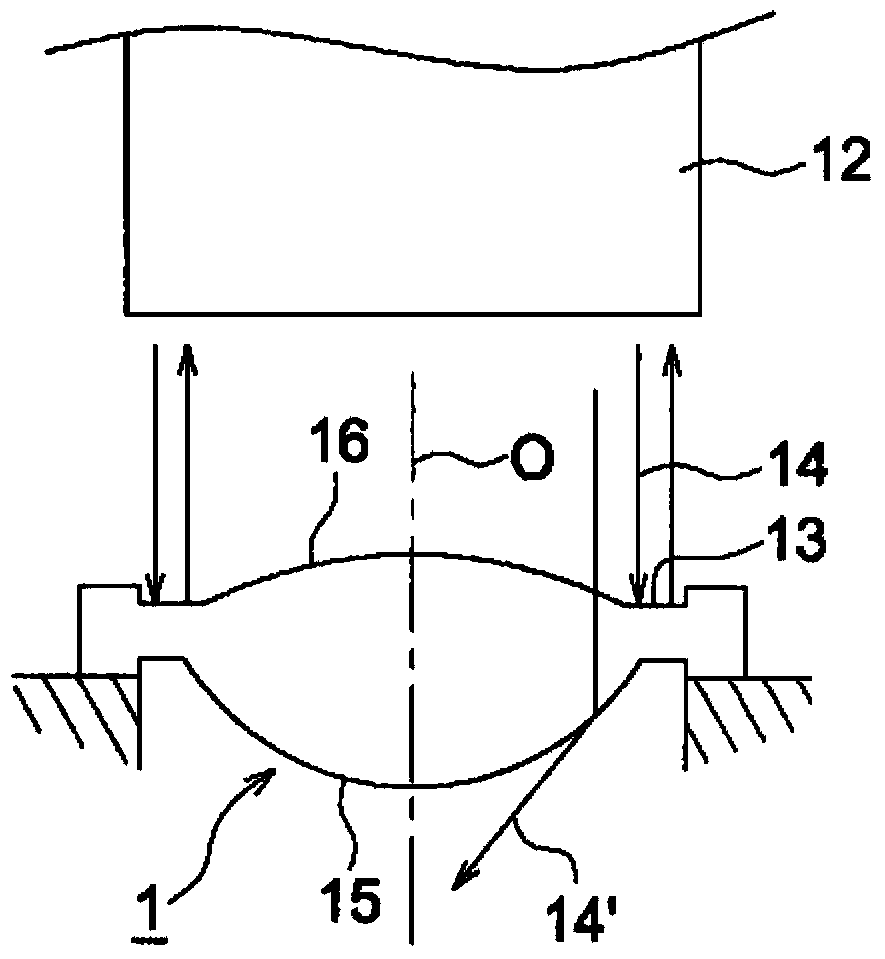

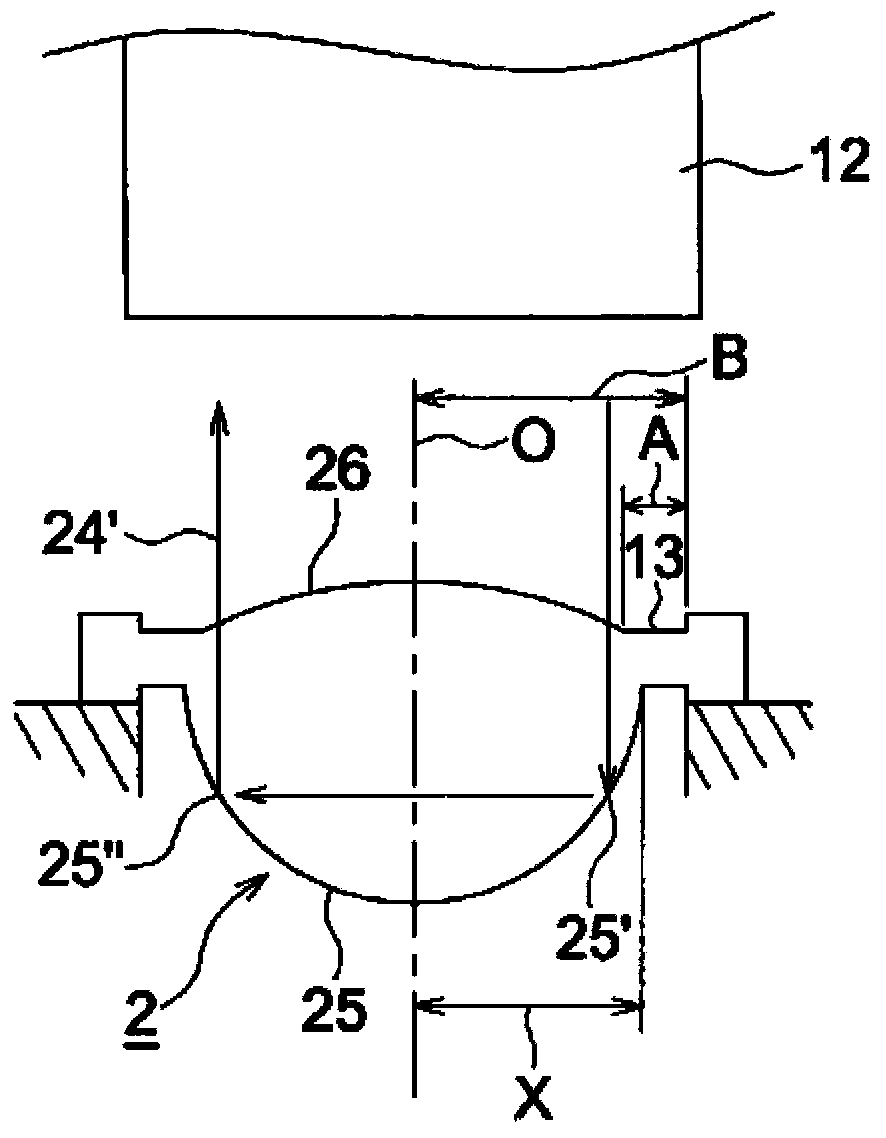

Embodiment 1

[0364] Figure 11 It is a sectional view of the objective lens 2a of Example 1. Figure 11 The objective lens 2a of the shown embodiment 1 is a plastic single-piece lens, which has a first optical surface 25 disposed facing the light source and a second optical surface 26 facing the first optical surface with a larger curvature than the first optical surface. An optical disc is arranged on the second optical surface 26 side.

[0365] Although not shown in figure, the optical path difference providing structure is formed in the 1st optical surface 25. As shown in FIG. The optical path difference imparting structure is a ring-shaped diffractive structure, and has a function of correcting spherical aberration caused by temperature change.

[0366] The numerical aperture of this objective lens 2a is 0.85, and it is a dedicated objective lens for BD corresponding to the laser beam of wavelength 405nm.

[0367] As shown in Table 1, the A / B value of the objective lens 2a is 0.26, ...

Embodiment 2

[0380] Figure 12 It is a sectional view of the objective lens 2b of Example 2. Figure 12 The objective lens 2b shown is a plastic single-lens lens having an optical path difference imparting structure substantially the same in shape as in Example 1, and the A / B value is changed.

Embodiment 3

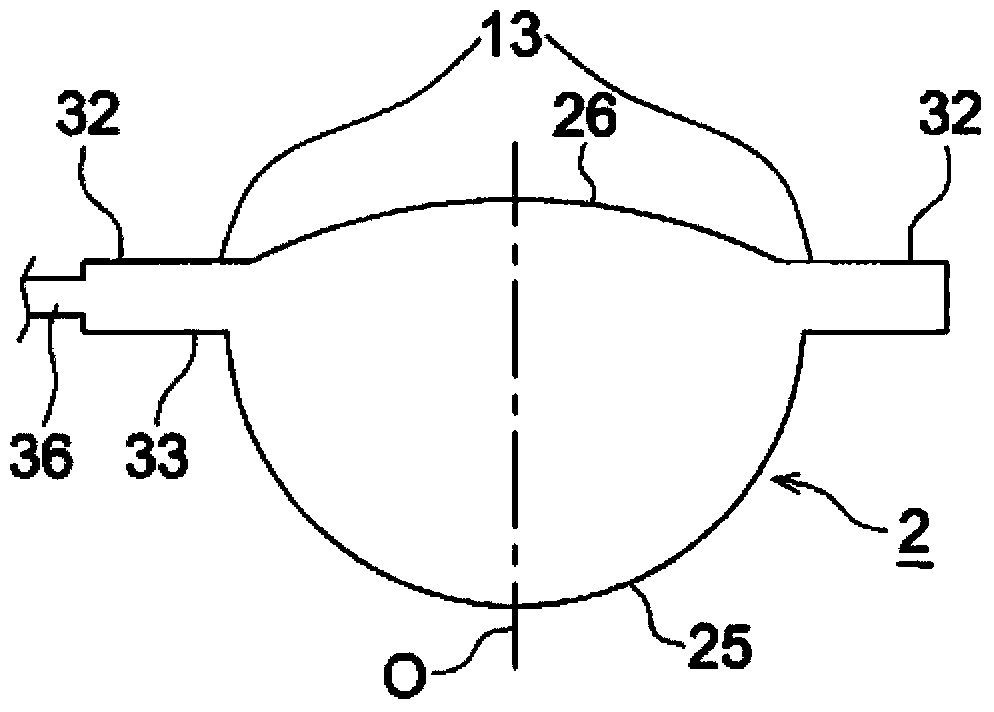

[0382] Figure 13 It is a sectional view of the objective lens 2c of Example 3. Figure 13 The objective lens of Example 3 shown is a plastic single-piece lens. The 1st optical surface 25 of the objective lens 2c of Example 3 is an aspherical shape which does not have an optical path difference providing structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com