Nozzle position correcting method for electronic device mounting apparatus

A technology of electronic devices and assembly devices, which is applied in the field of nozzle positioning correction, can solve problems such as direction changes, nozzle positioning errors, and photographic position errors are not close to each other, and achieve the effect of accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] (overall structure of the embodiment)

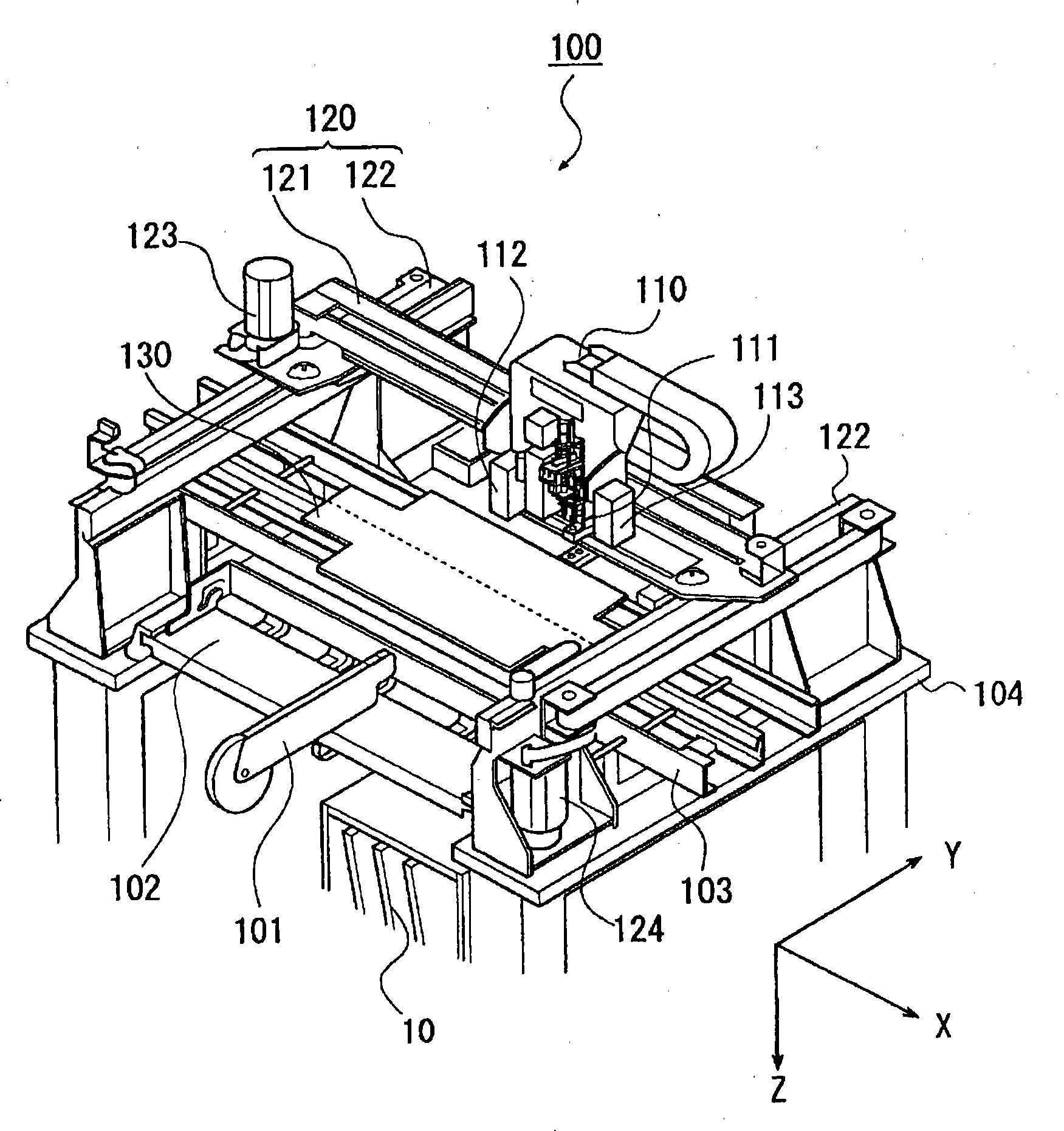

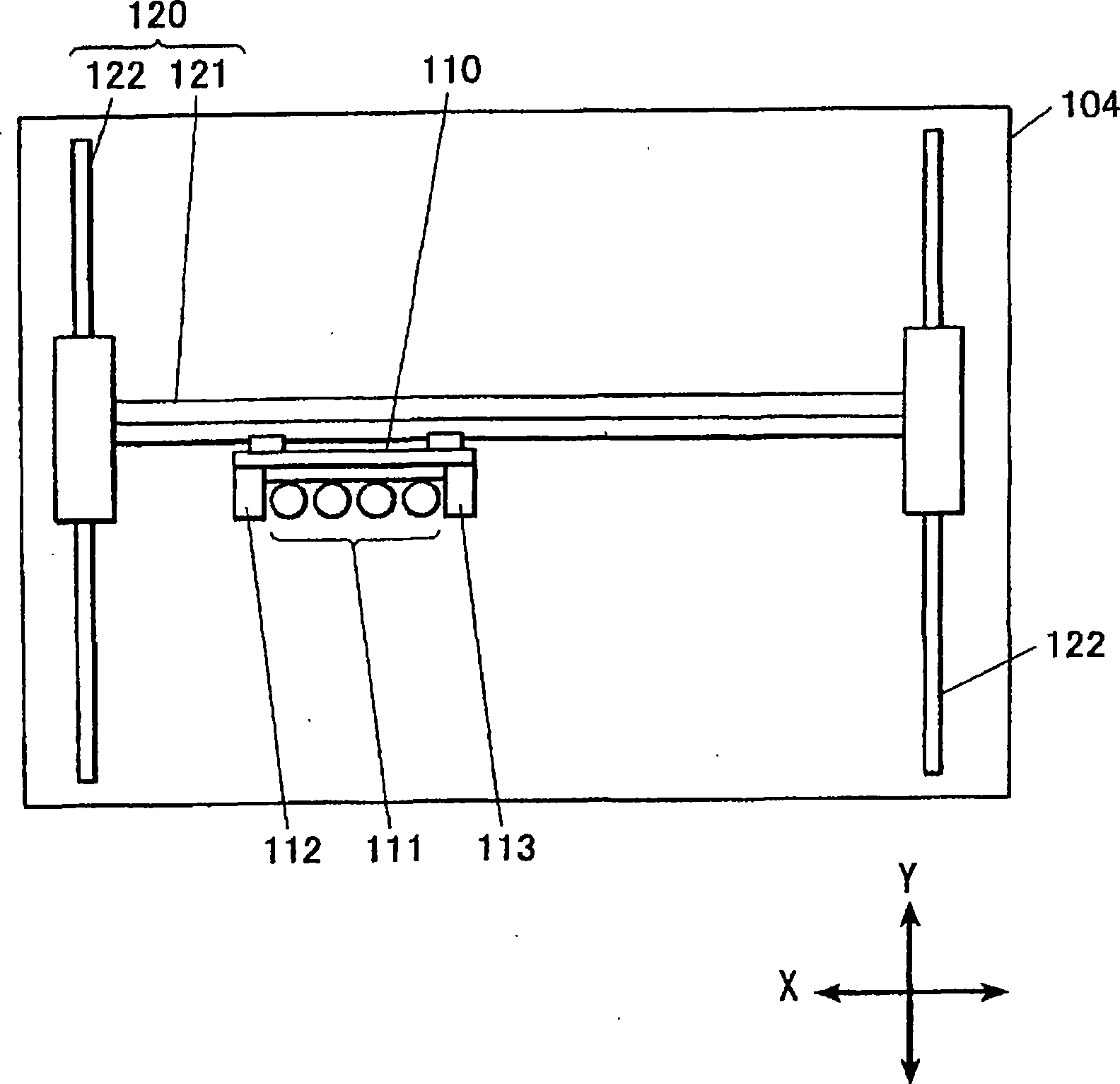

[0055] For the embodiment of the present invention, according to Figure 1 to Figure 14 Be explained. figure 1 It is a perspective view of the electronic component mounting apparatus 100 of this embodiment.

[0056] The electronic device mounting apparatus 100 is an apparatus for mounting various electronic devices on a substrate. Such as figure 1 As shown, there are: a base 104, which supports the various components described later; a plurality of electronic device feeders 101 (in figure 1 Only one is shown in the figure, in fact, there are multiple arranged along the X-axis direction described later), which supplies the electronic devices to be assembled; the feeder workbench (bank) 102, which is used to arrange and hold multiple Electronic device feeder 101; substrate conveying device 103, which conveys the substrate along a certain direction; on the way of the substrate conveying path of the substrate conveying device 103,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com