Large aluminum profile straightening machine automatic lifting and feeding mechanism

A feeding mechanism and automatic lifting technology are applied in the field of automatic lifting and feeding mechanism of large-scale aluminum profile straightening machines, which can solve the problems of the length of the scrap head, the quality of the deformed material in the flexible zone, and the difficulty of clamping the front and rear jaws, and reduce the The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below.

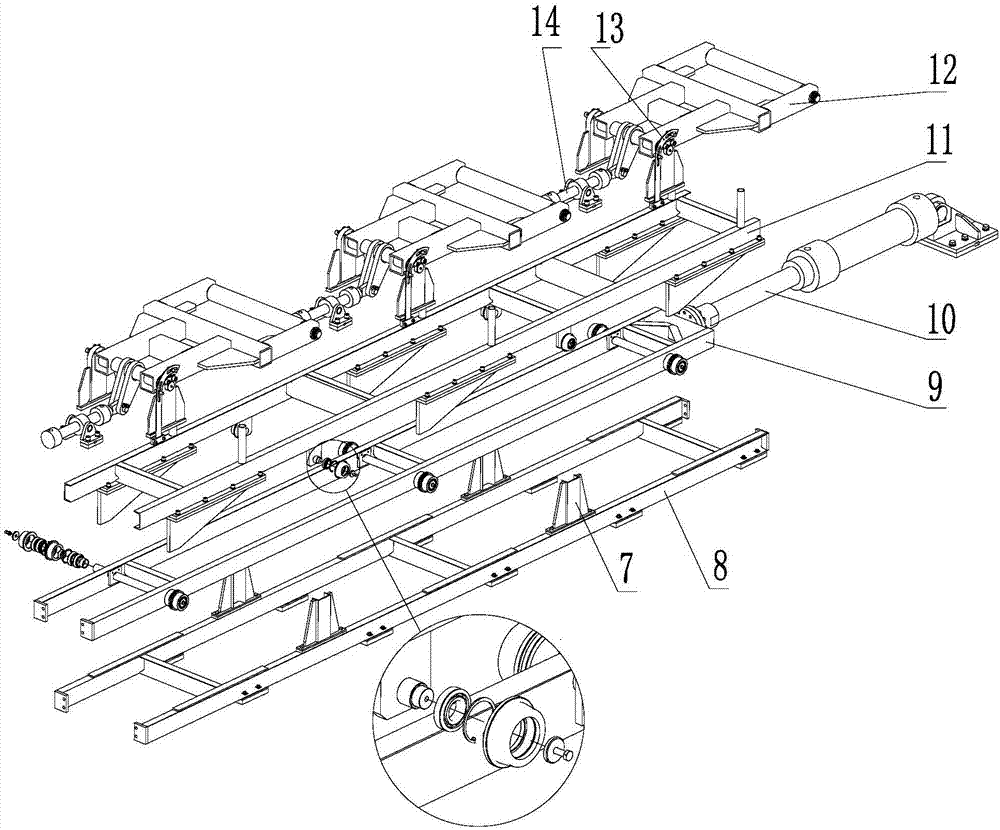

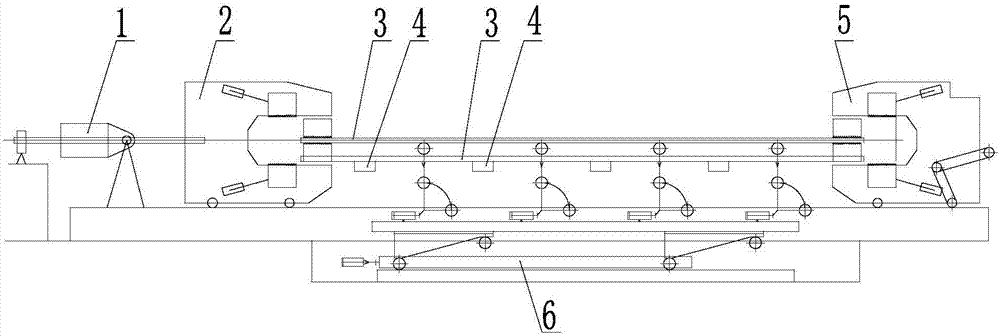

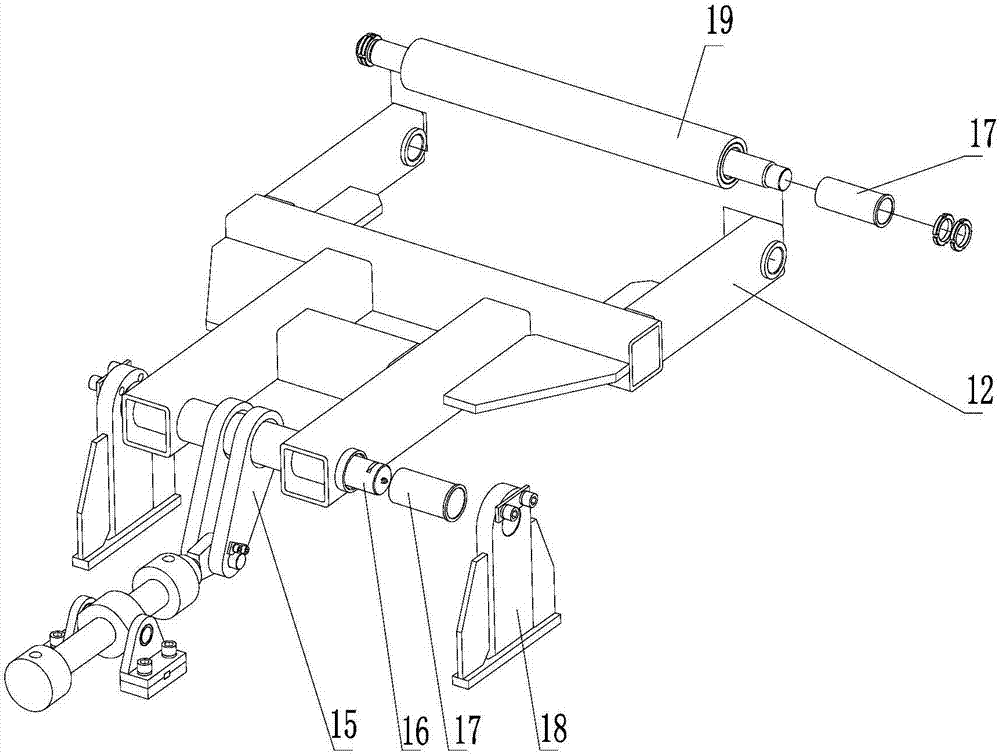

[0026] The reference signs in the drawings of the description include:

[0027] Main stretching cylinder 1, moving jaw 2, profile to be orthopedic 3, horizontal feeding conveyor belt 4, fixed jaw 5, lifting feeding mechanism 6, limit frame 7, bottom frame 8, middle frame 9, lifting cylinder assembly 10. Upper frame 11, swing frame 12, position detection switch 13, swing cylinder assembly 14, crank arm 15, rotating shaft 16, sliding bearing 17, support 18, support roller 19.

[0028] Such as figure 2 The automatic lifting and feeding mechanism of the aluminum profile straightening machine shown includes the profile to be corrected 3, the lifting and feeding mechanism 6, the movable end jaw 2 and the fixed end jaw 5 installed on both sides of the lifting and feeding mechanism 6 with opposite openings , the fixed end jaw 5 is fixedly installed on the frame outside the lifting and feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com