A metal workpiece edge folding machine with three degrees of freedom

A technology of metal workpieces and degrees of freedom, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of affecting the rigidity and strength of the mold, poor flexibility, and easy interference with the workpiece, so as to avoid interference collision and edge folding The effect of high precision and large bending angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

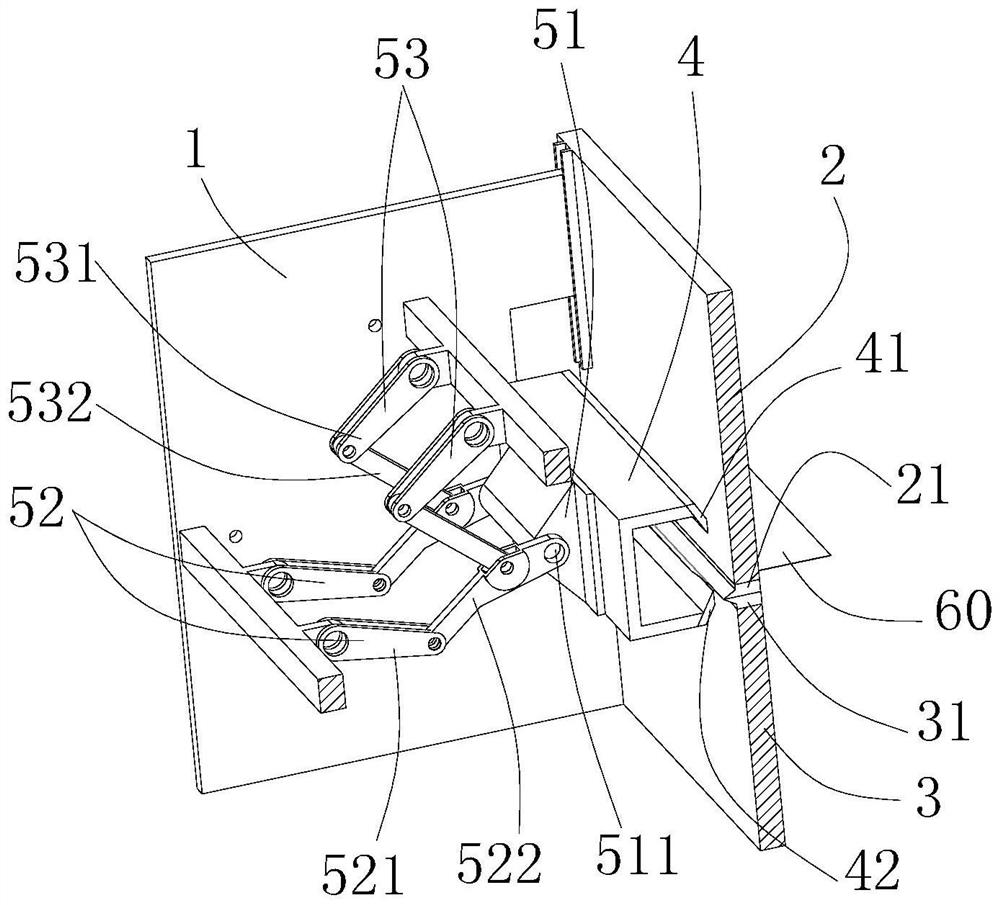

[0047] Such as figure 1 As shown, the slider is vertically slidably installed on the frame directly above the fixed block, and the upper die slides vertically up and down with the slider to achieve height adjustment.

[0048] Second embodiment

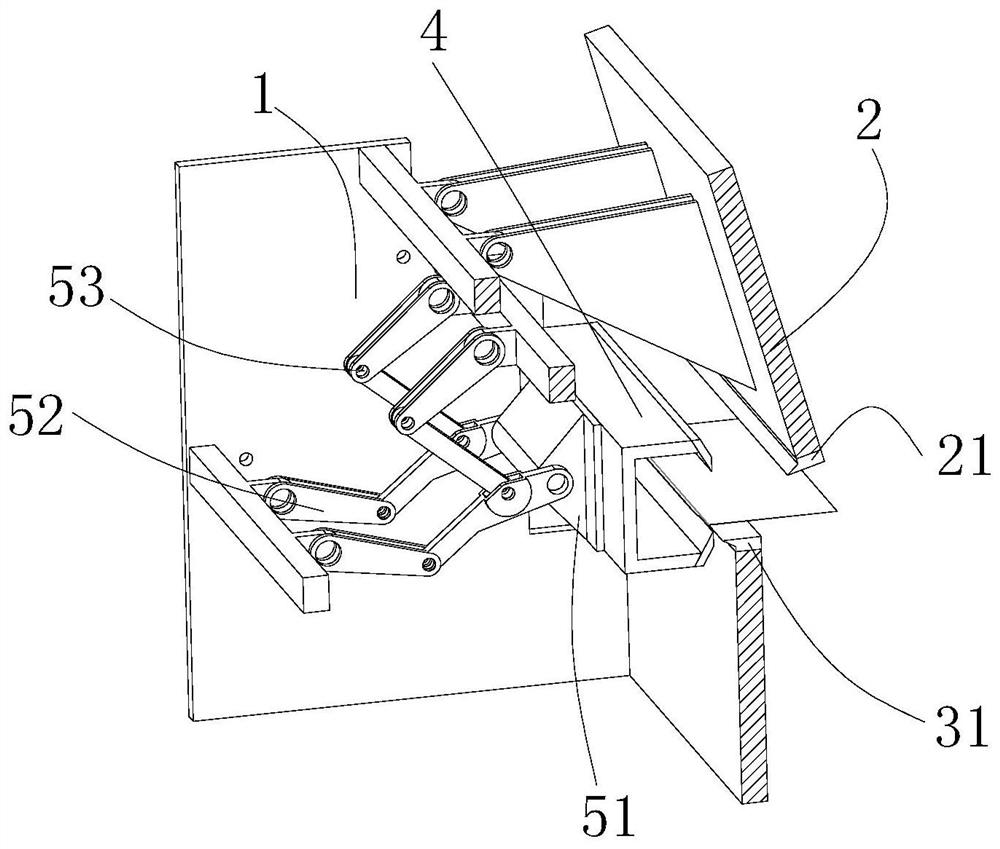

[0049] Such as figure 2 As shown, the slider is flipped and installed on the frame directly above the fixed block, and the upper die is flipped with the slider to achieve height adjustment.

[0050] A hemming die is installed on the hemming beam, and the hemming die is used for hemming the metal workpiece, including a hemming upper die 41 and a hemming lower die 42 . In this embodiment, the hemming beam is preferably C-shaped, and the hemming upper die 41 and the hemming lower die 42 are respectively arranged at the C-shaped opening of the hemming beam.

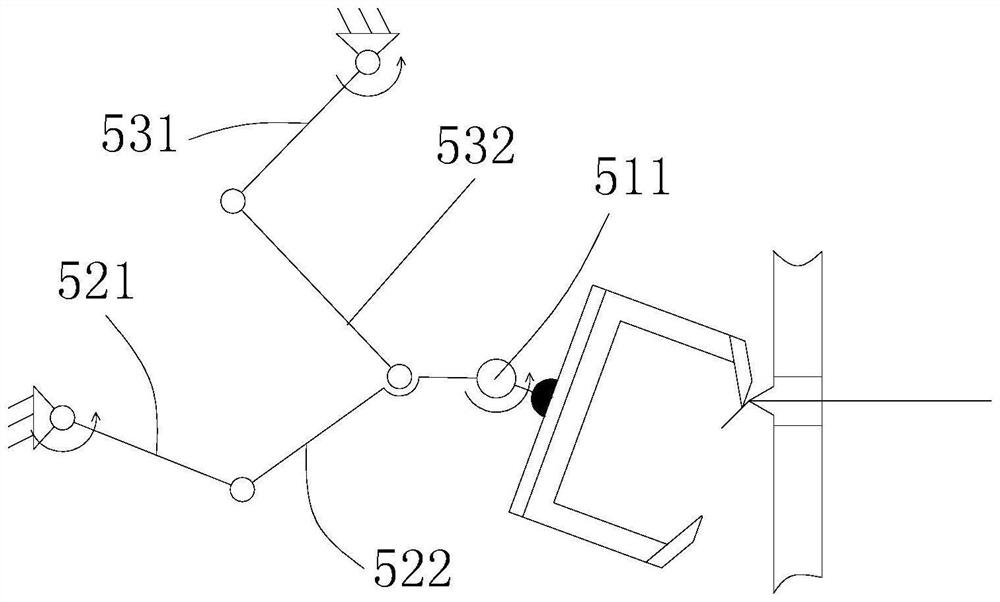

[0051] Under the action of the hemming transmission mechanism, the hemming beam can move in three degrees of freedom, horizontally, vertically and rotationally.

[0052] The hemm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com