Hot-pressing machine of pocket cloth edgefolds of uniform clothes

A pressing machine and clothing technology, which is applied to sewing tools, washing devices, transportation and packaging, etc. It can solve the problems of seam head ironing, waste of fabric, and low work efficiency, and achieve hemming pressing and straightening. Smooth, improve the folding precision, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

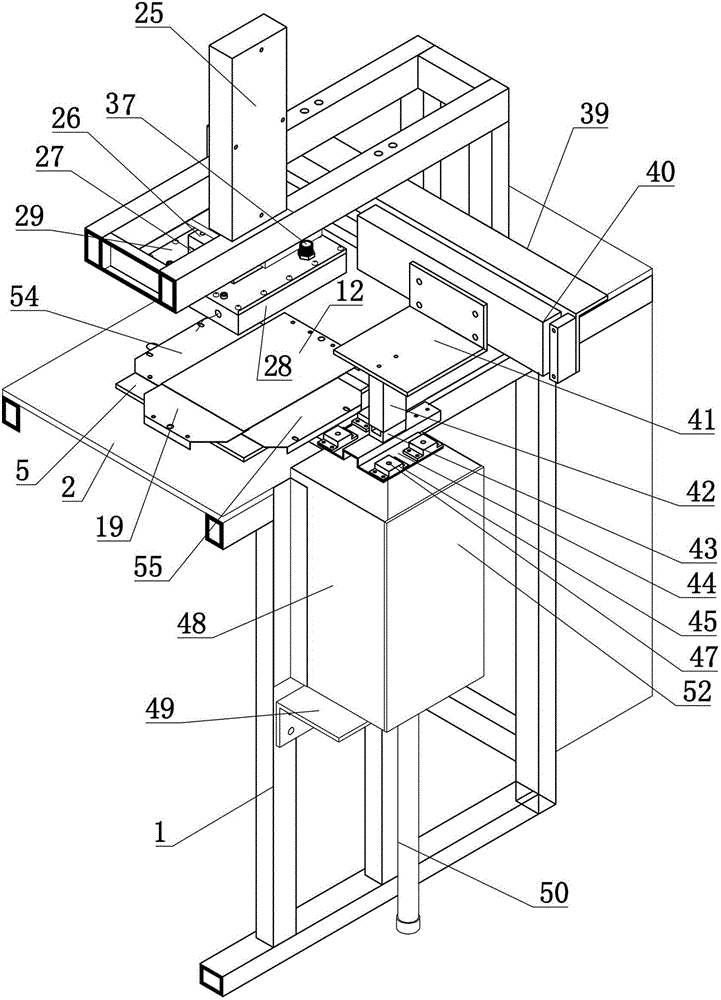

[0030] as attached figure 1 As shown, the present invention includes a frame 1, a working platform 2 fixedly installed in the middle of the frame 1, a folding and ironing device installed in the middle of the working table 2, a folding device installed above, below and on the left side of the folding and ironing device, and an installation On the top of the frame 1, there is a pressing device corresponding to the creasing device and a finished product stacking device installed on one side of the pressing device.

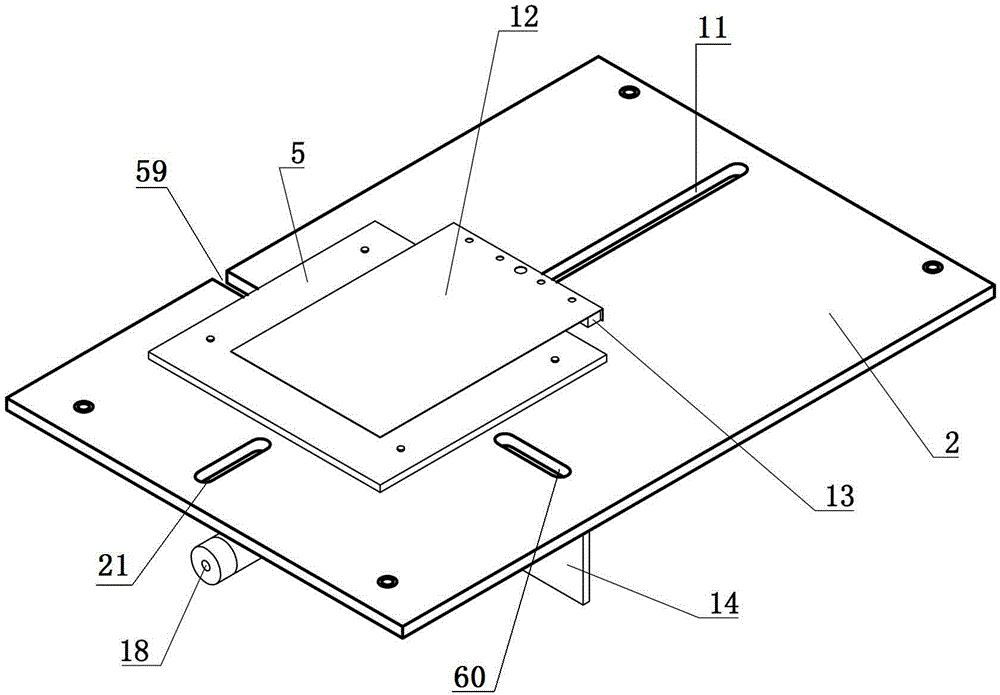

[0031] as attached figure 2 , 3 , 5 and 6, right slot 11, left slot 21, upper slot 59 and lower slot 60 are set on the working platform 2 of the present invention.

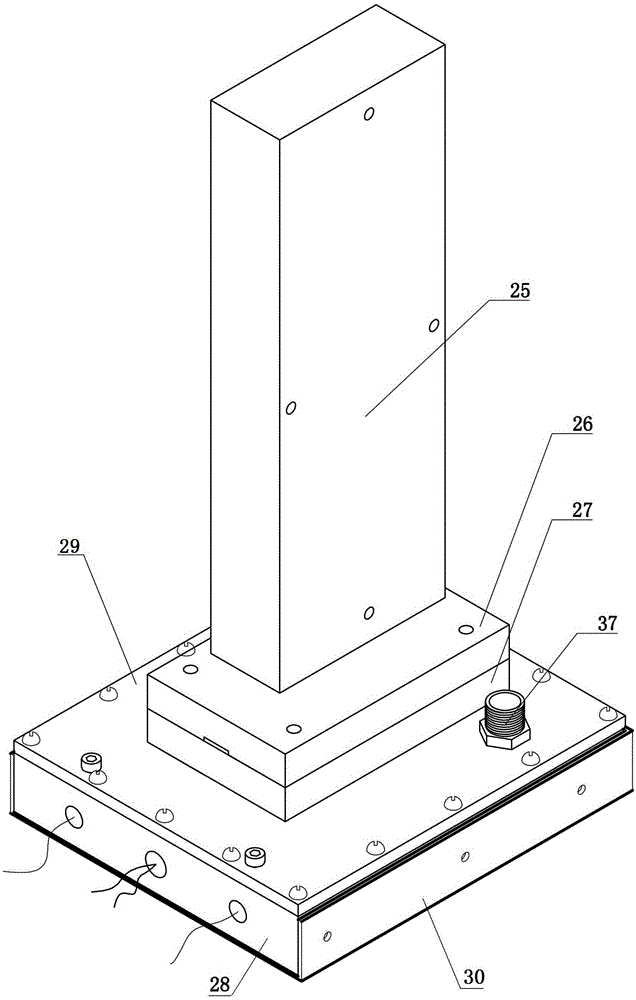

[0032] as attached figure 1 , 2 , 3, 4, and 16, the folding and ironing device of the present invention includes a folding and ironing mold installed on the working platform 2 and a driving device installed on the bottom surface of the working platform 2; the folding and ironing mold includes a bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com