A pressing device of a standard garment pocket cloth folding and pressing machine

A pressing machine and clothing technology, which is applied in the direction of sewing tools, washing devices, stacking receiving devices, etc., can solve the problems of seam head ironing, waste of fabric, low work efficiency, etc., and achieve the smoothness of folding and pressing Straightforward, simple and convenient operation, and the effect of improving the accuracy of folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

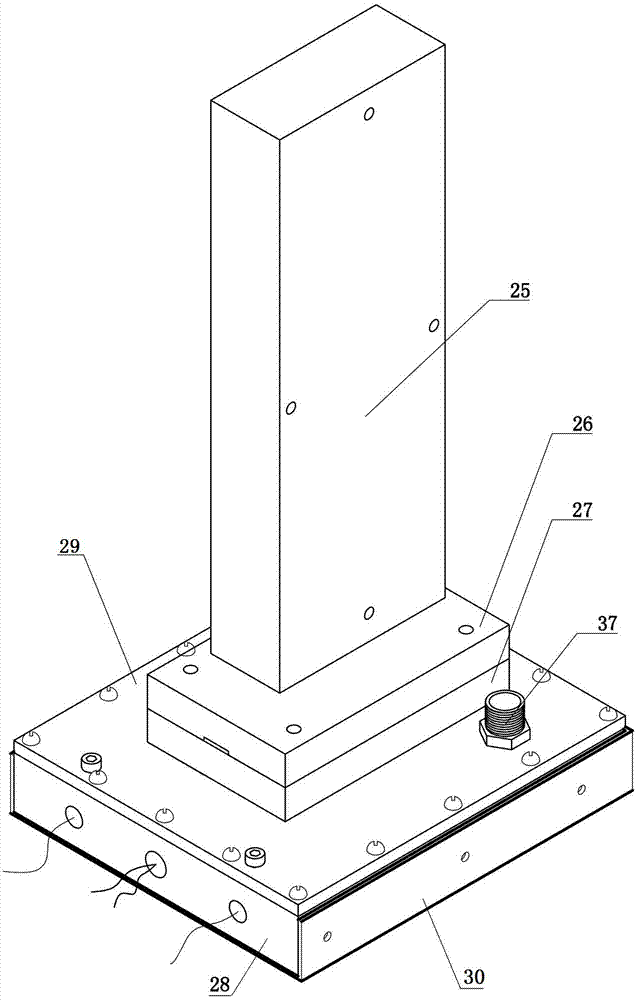

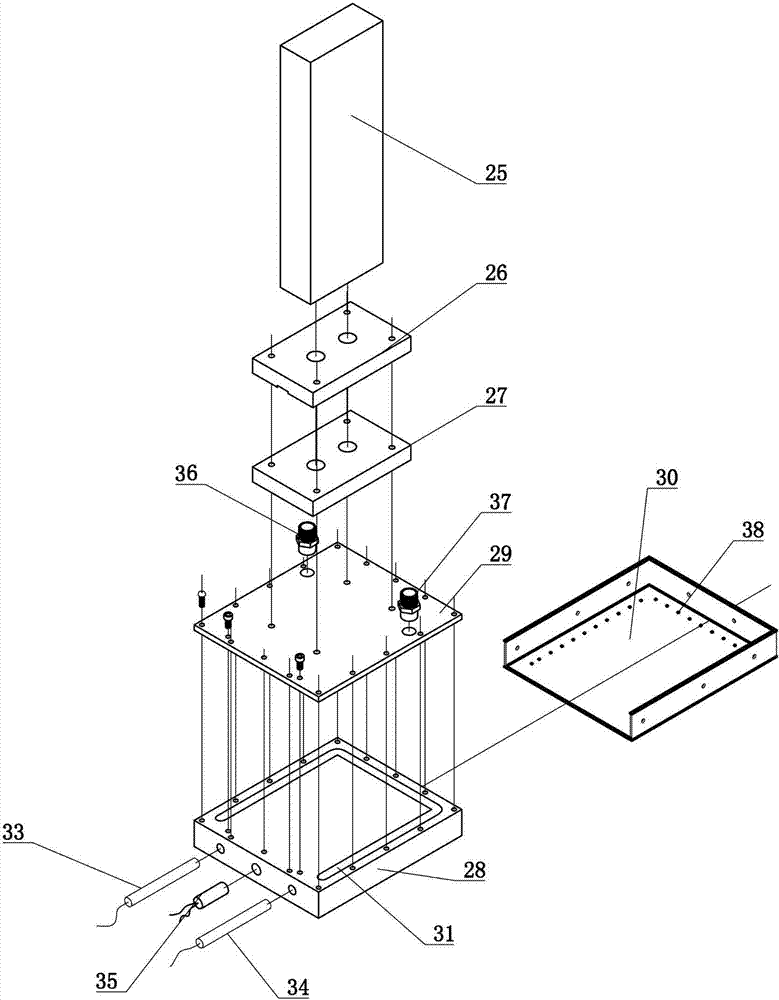

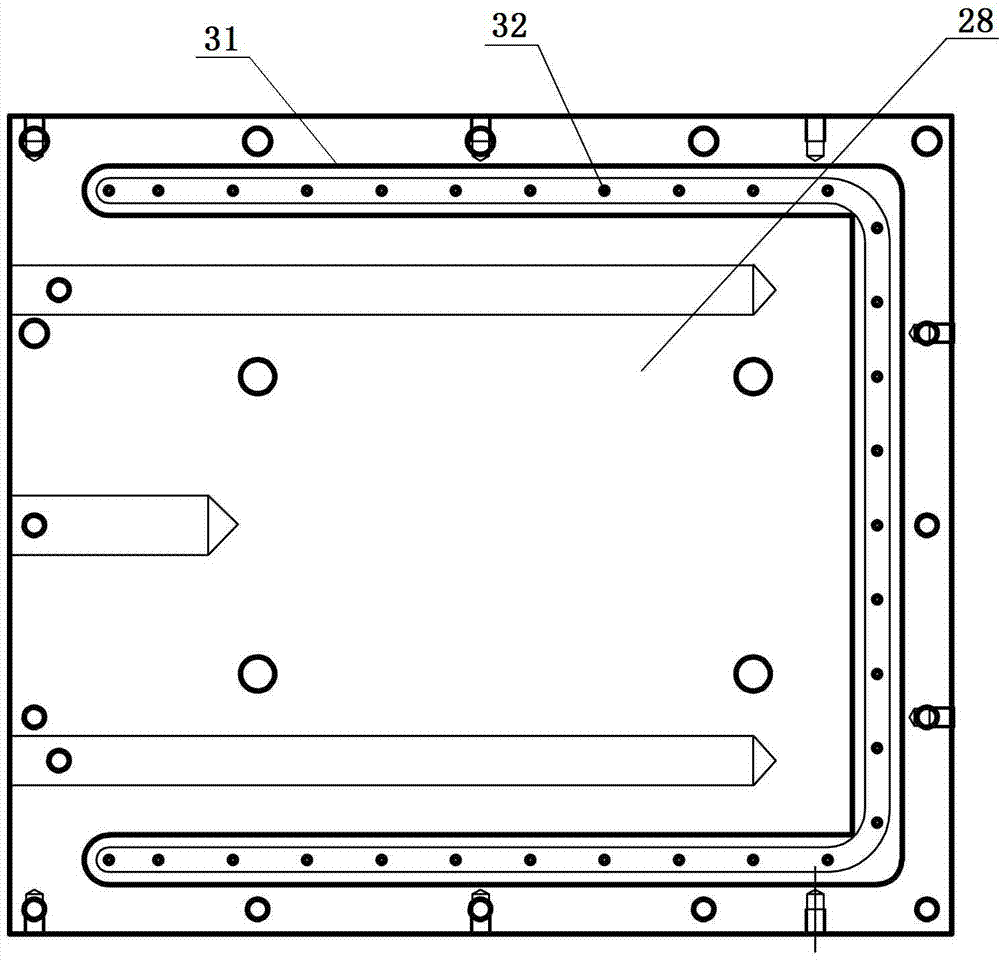

[0024] as attached figure 1 , 2 , 4, and 16, the pressing device of the present invention includes a soldering iron lifting cylinder 25 fixedly mounted on the top of the frame 1, a soldering iron connecting plate 26 fixedly mounted on the lower end of the soldering iron lifting cylinder 25 piston rod, and a soldering iron connecting plate 26 fixedly mounted on the lower end of the soldering iron connecting plate 26. The non-metallic heat shield 27 and the soldering iron device fixedly installed on the lower end of the non-metallic heat shield 27; the soldering iron lifting cylinder 25 is a double-axis cylinder TN32×200-S; the soldering iron device includes a soldering iron 28, fixedly installed on the soldering iron The soldering iron upper cover 29 on the soldering iron 28 and the soldering iron shoe 30 fixedly installed on the lower end of the soldering iron 28, the soldering iron 28 is set shaped steam groove 31, in Steam injection holes 32 are evenly arranged in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com