Supply conveying system for activated carbon manufacturing

A conveying system and activated carbon technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of increasing labor intensity of workers, waste of activated carbon materials, and falling of activated carbon raw materials, so as to reduce manual workload and reduce Effect of friction, enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

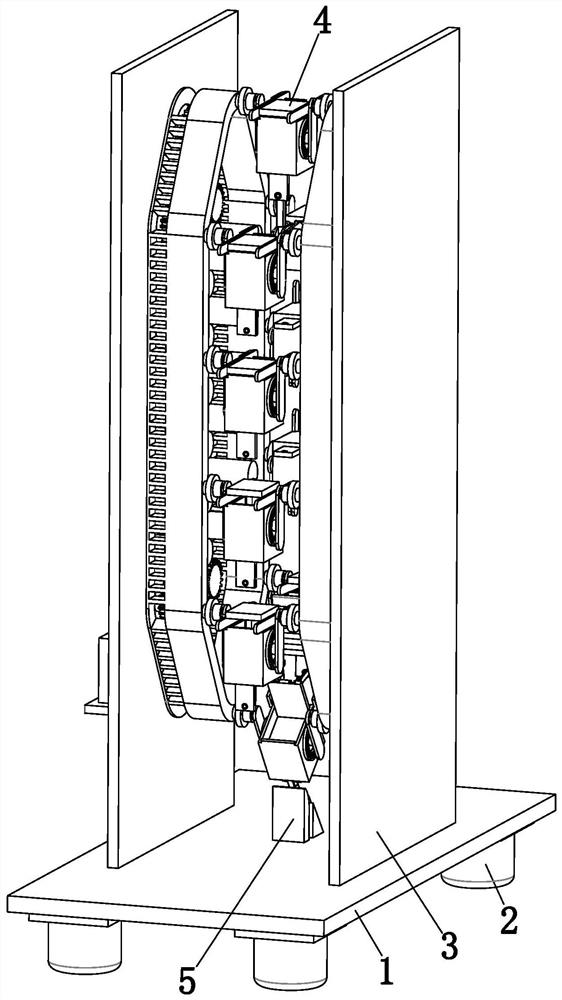

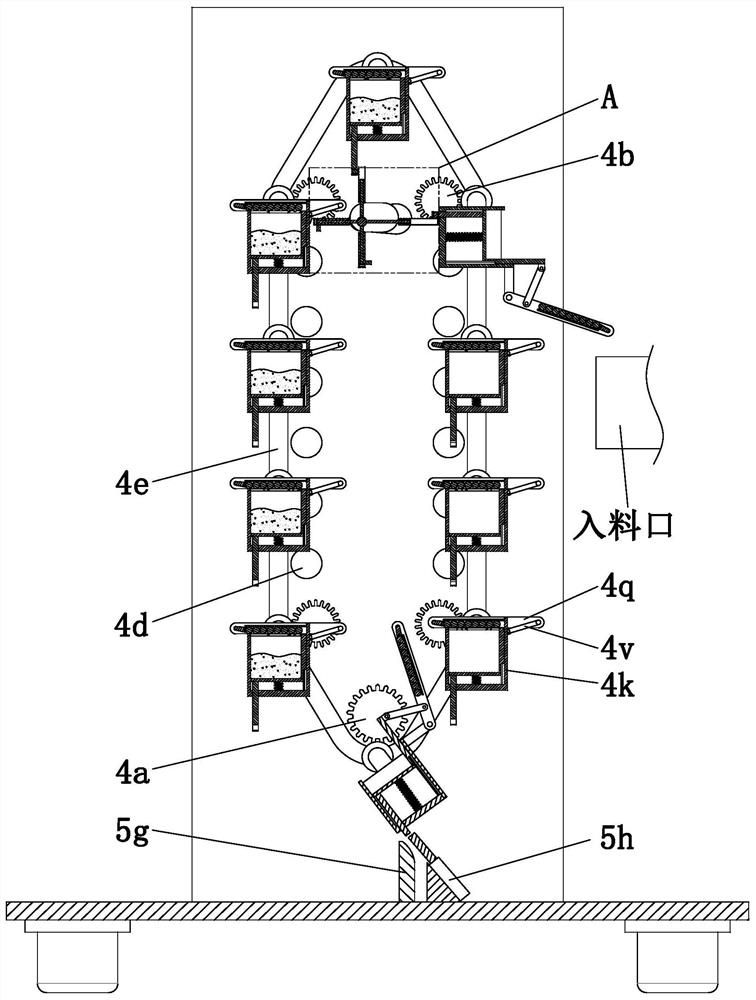

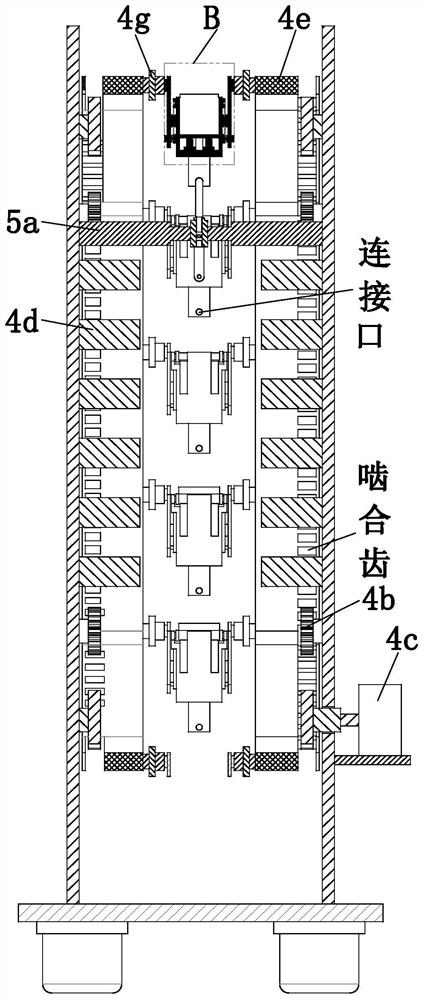

[0022] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 6 , to further elaborate the present invention.

[0023] A supply and conveying system for activated carbon production, comprising an installation base plate 1, a support foot 2, a frame 3, a conveying mechanism 4 and an overturning mechanism 5, the corners around the lower end of the installation base plate 1 are uniformly equipped with support feet 2, and the installation base plate The upper end of 1 is equipped with 匚-shaped frame 3, between the 3 inner walls of 匚-shaped frame 3, conveying mechanism 4 is installed by rotating, and in the 匚-shaped frame 3, turning mechanism 5 is installed by rotating and fitting, and turning mechanism 5 is positioned at conveying mechanism 4 inboards.

[0024]The conveying mechanism 4 includes a drive gear 4a, a limit gear 4b, a drive motor 4c, a support shaft 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com