Automatic sand-gravel aggregate bagging and conveying device

A technology of conveying device and sand and gravel material, which is used in automatic control of packaging, packaging, packaging machines, etc., can solve the problems of manual control of bagging quantity, poor bagging efficiency, vertical falling, etc., to achieve smooth discharge and accurate measurement. , The effect of preventing material blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

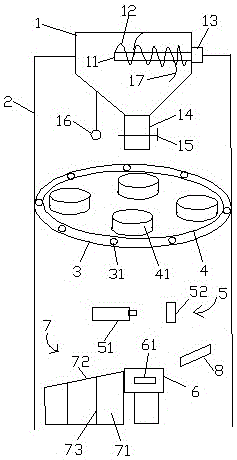

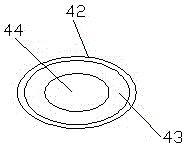

[0028] Such as figure 1 and figure 2 As shown, an automatic bagging and conveying device for sand and gravel materials, which has a hopper 1, a stirring rod 11, a propeller blade 12, a motor 13, a discharge port 14, a solenoid valve 15, a vibrating pendulum 16, a claw 17, a fixed Frame 2, turntable fixing seat 3, bearing 31, turntable 4, woven bag fixing seat 41, electromagnet 42, metal pressing block 43, through hole 44, sealing machine 5, sealing head 51, nail plate 52, jacking platform 6. Main technical features such as load cell 61, splicing transmission line 7, splicing frame 71, smooth plate 72, lifting legs 73 and telescopic push rod 8.

[0029] An automatic sand and gravel material bagging and conveying device includes a hopper, a fixed frame, a turntable fixed seat, a turntable, a binding machine, a jacking pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com