Liquid material filling equipment

A technology for filling equipment and liquids, which is applied in the direction of liquid distribution, transportation or transfer devices, special distribution devices, packaging, etc., and can solve the problems of inability to flexibly use multiple sites, complex structure and functions, and heavy fillers, etc., to achieve Compact structure, convenient operation, and the effect of reducing pipeline leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

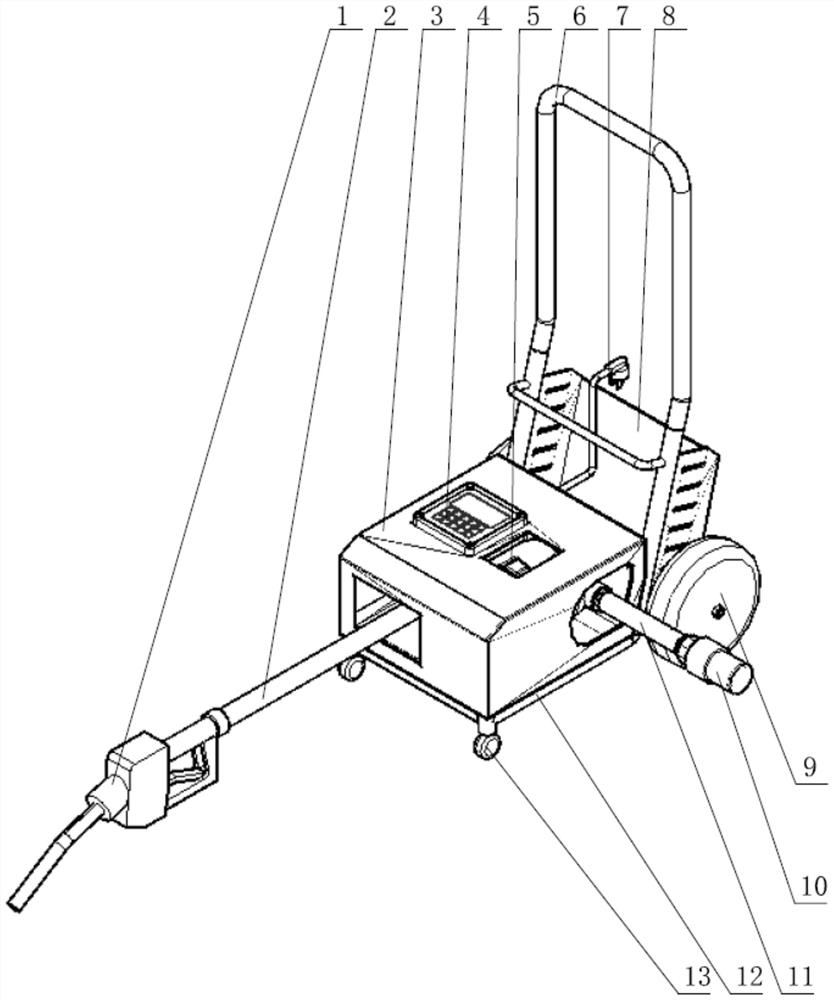

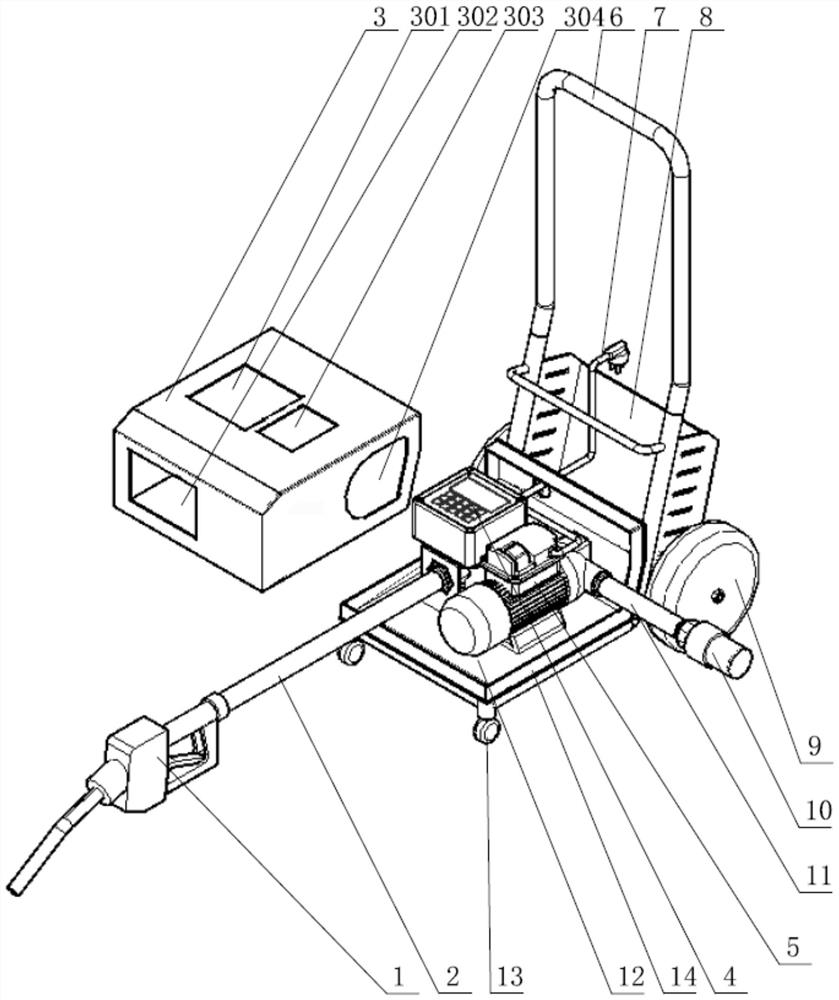

[0024] Such as figure 1 with figure 2 As shown, the portable liquid material filling device of the present embodiment includes a cart body 12, a pump 5 is fixedly installed on the base of the cart body 12, a liquid injection pipe 11 is installed at the input port of the pump 5, and the liquid injection pipe 11 The liquid input filter screen 10 is installed on the pipe head of the pump 5, and the liquid output pipe 2 is installed on the output port of the pump 5. The directional gear flowmeter 4 is installed on the liquid output pipe 2, and the hand-held liquid filling gun head 1 is installed on the pipe head of the liquid output pipe 2. ;

[0025] An outer edge 14 is arranged around the base of the cart body 12, and a filler housing 3 is installed at the outer edge 14, and the filler housing 3 covers the pump 5 and the directional gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com