Patents

Literature

34results about How to "Improve down filling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

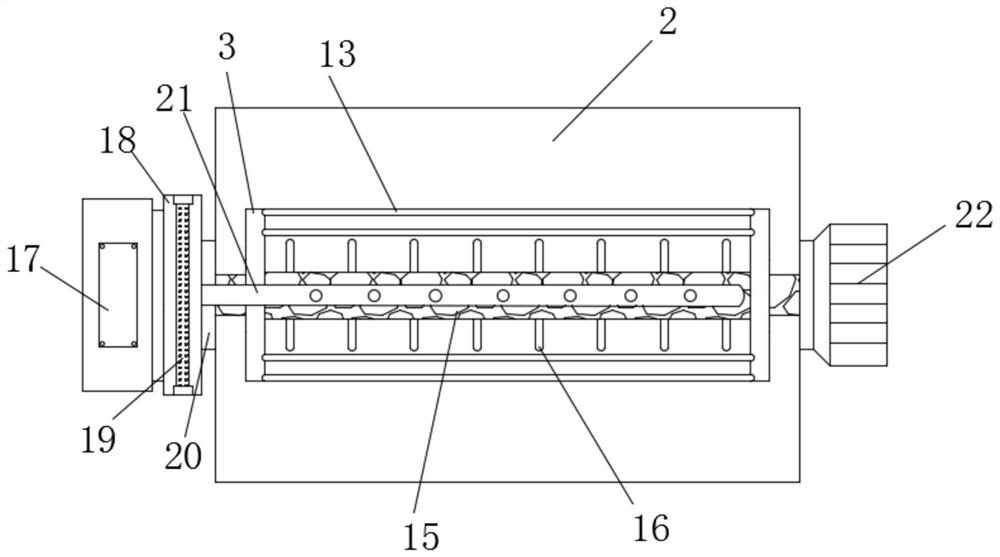

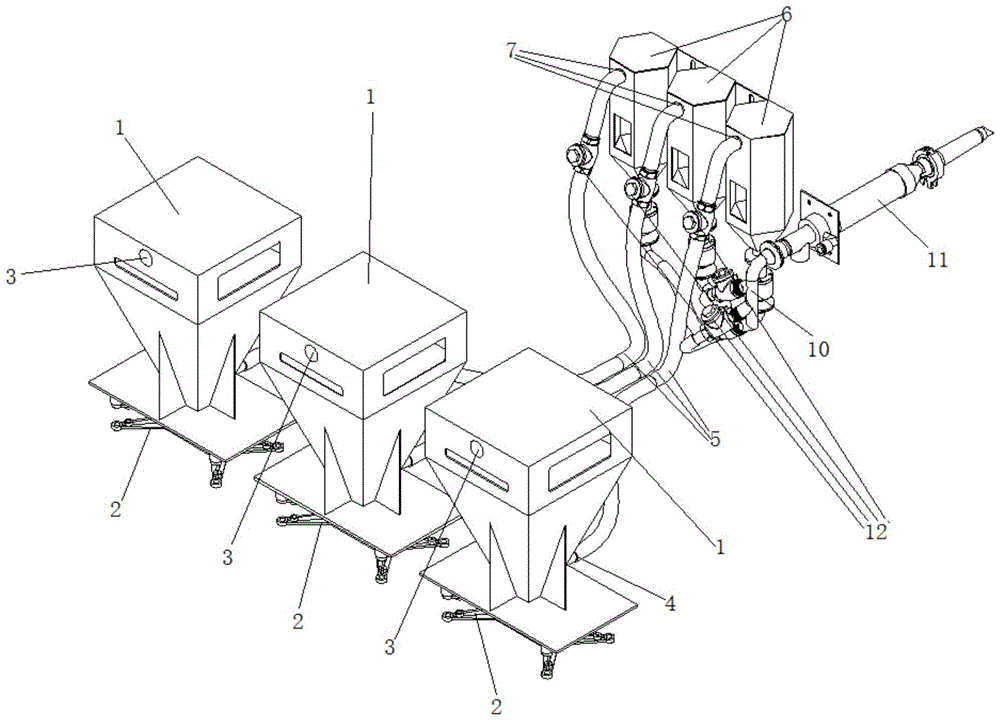

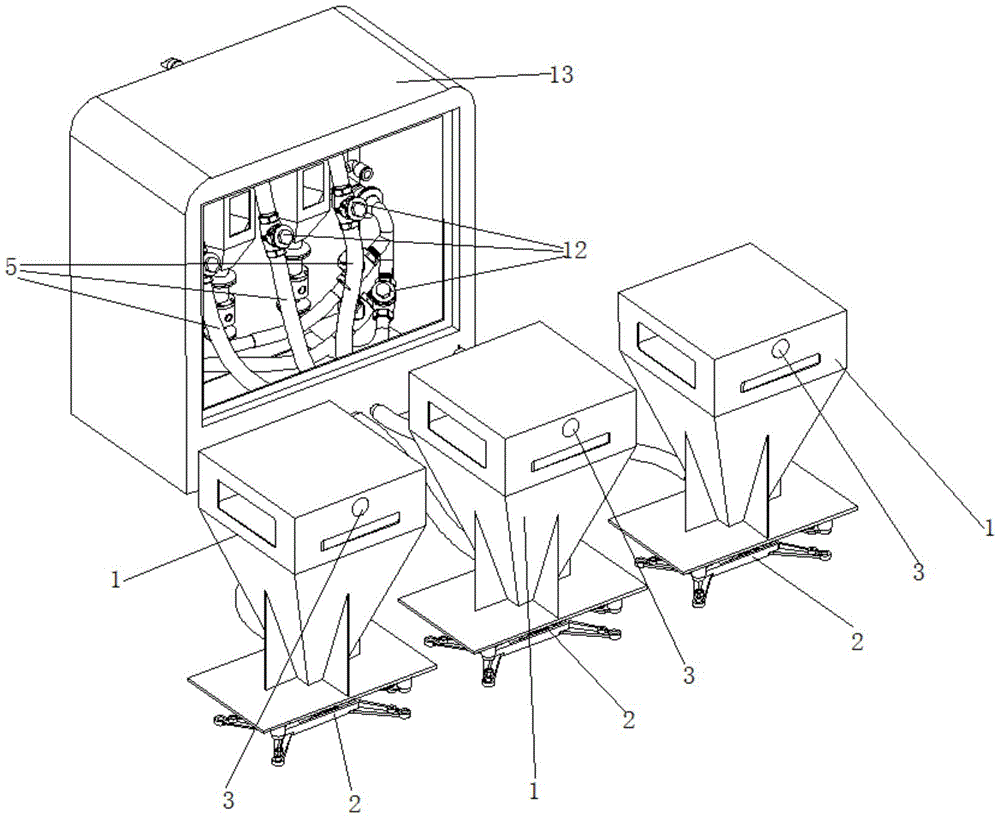

Down filling machine

ActiveCN102808245AStable outputHighly stable suedeUpholstery manufactureOakum treatmentEngineeringUltimate tensile strength

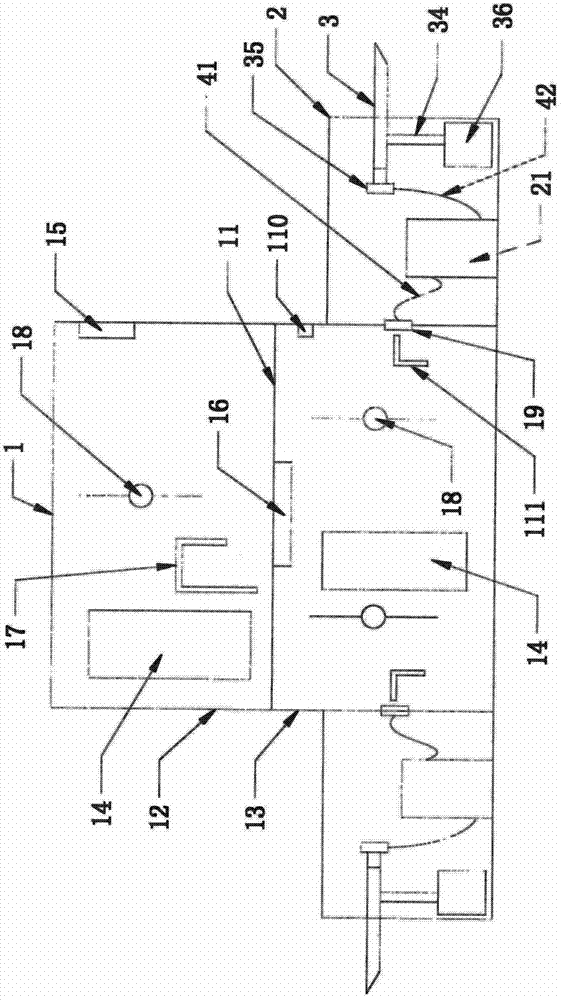

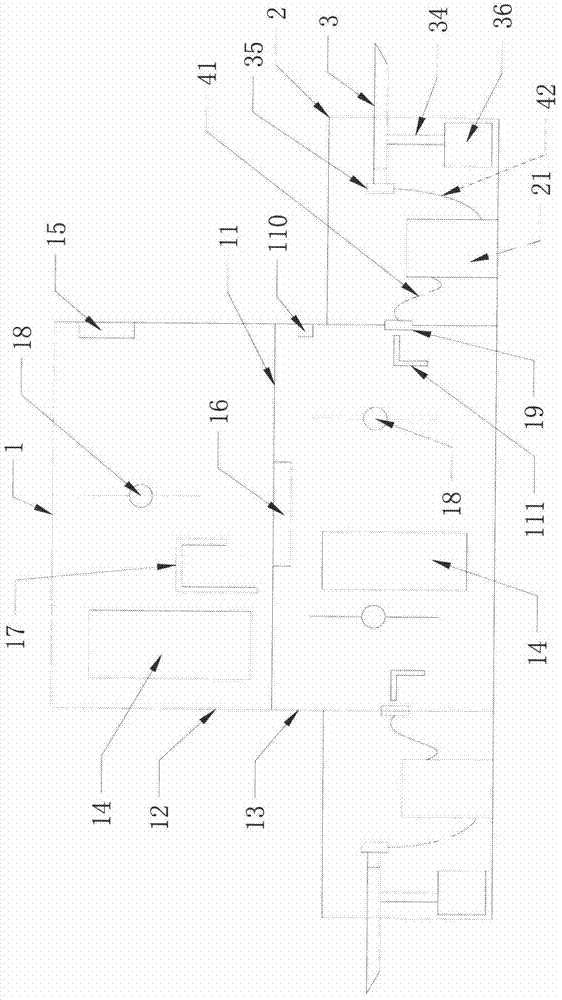

The invention discloses a down filling machine, which comprises a down storage box, weighing cabinets, down filling pipes and a programmable controller, wherein the down storage box is provided with at least two weighing cabinets; at least two weighing boxes are arranged in each weighing cabinet; the total number of the weighing boxes is equal to the total number of down outlets of the down storage box; each weighing cabinet is provided with at least one down filling pipe; the total number of the weighing boxes in each weighing cabinet is dual, and the number of the down filling pipes is a half of the total number of the weighing boxes. According to the down filling machine, the close full-automatic down filling can be carried out, the labor intensity is reduced, the production efficiency is improved, and the production cost is decreased. The down filling machine has the advantages of reasonable design, simple structure, low cost and good practicability. The down storage box of the down filling machine has stable down output, so that the down filling consistence and the down filling precision are ensured; a weighing process of the weighing boxes is independent, precise and effective; the down filling pipes cannot fill the down to airtight cutting pieces; working conditions of the multiple weighing boxes are alternatively changed and one down filling pipe is used for outputting, so that the down filling efficiency is further improved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

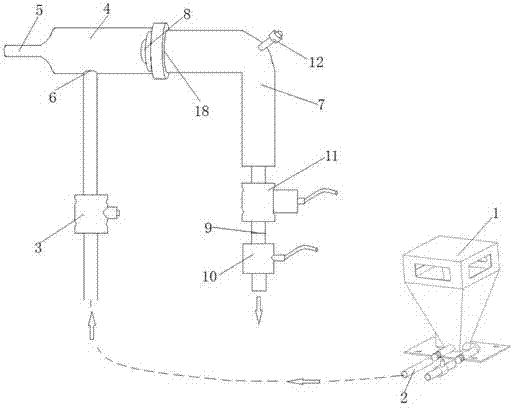

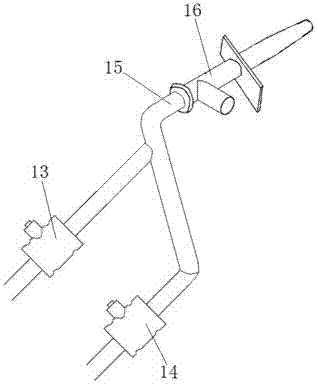

Automatic quantitative down-filling machine

InactiveCN101779837BImprove down filling efficiencyRealize quantitative weighingUpholstery manufactureClothes making applicancesAutomatic controlSolenoid valve

Owner:CHINA JILIANG UNIV

Automatic quantitative down-filling machine

InactiveCN101779837AImprove down filling efficiencyRealize quantitative weighingUpholstery manufactureClothes making applicancesAutomatic controlSolenoid valve

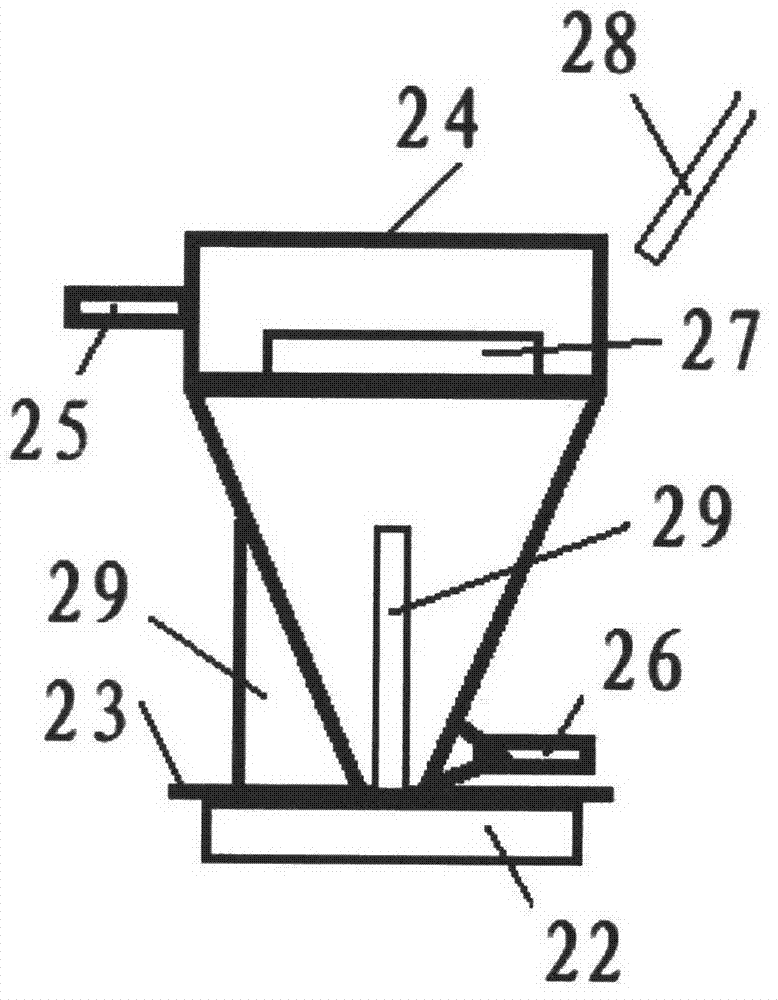

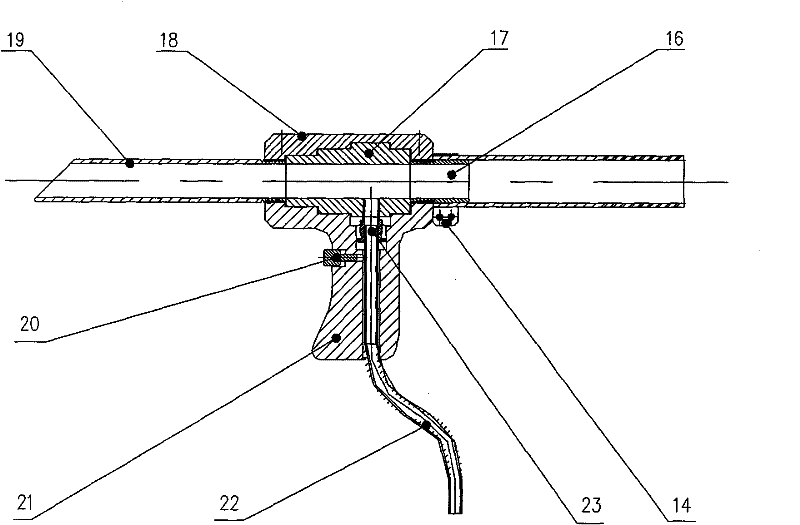

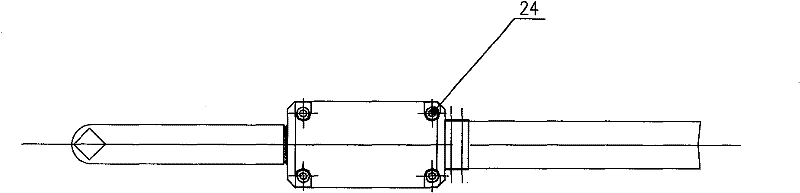

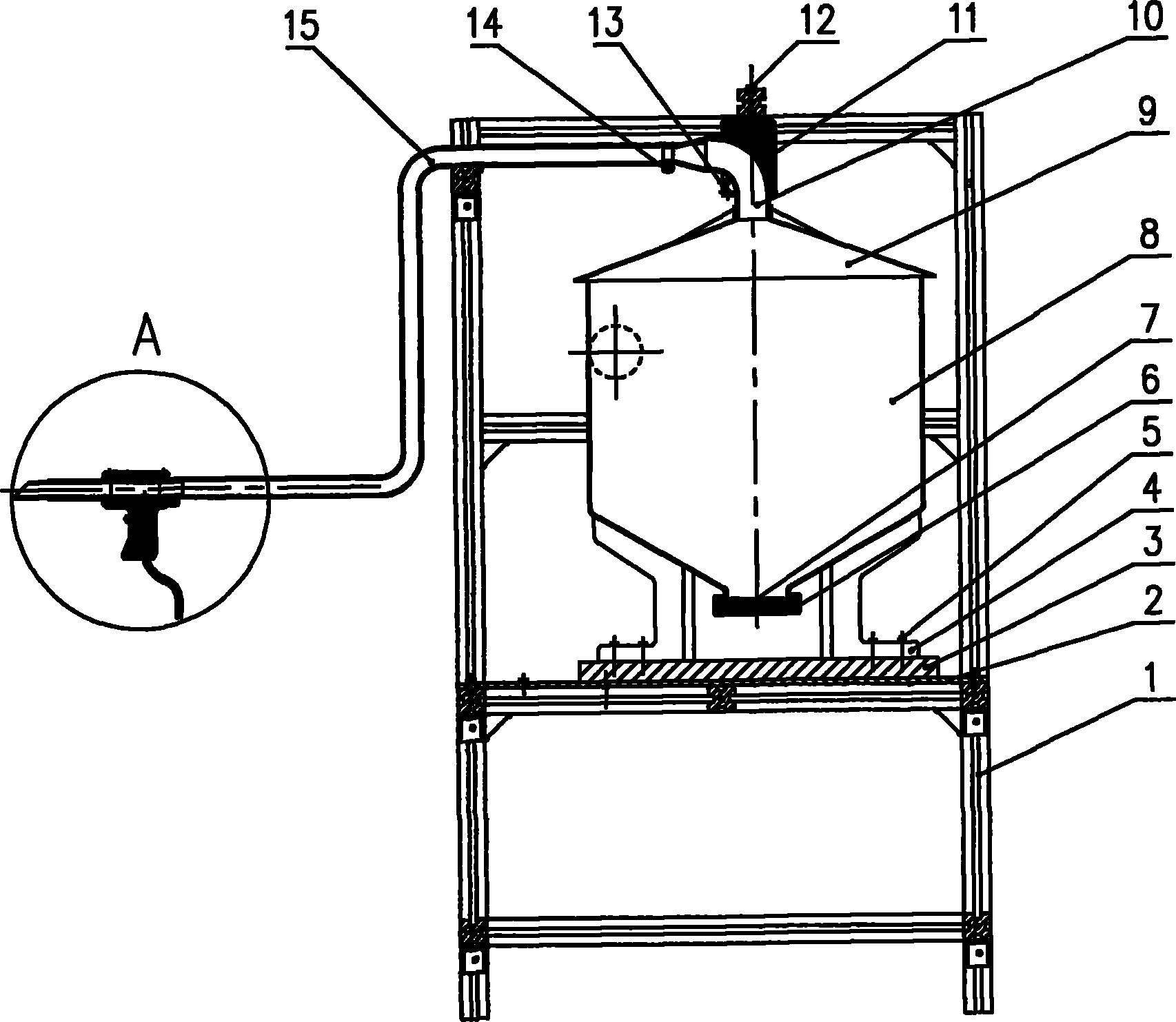

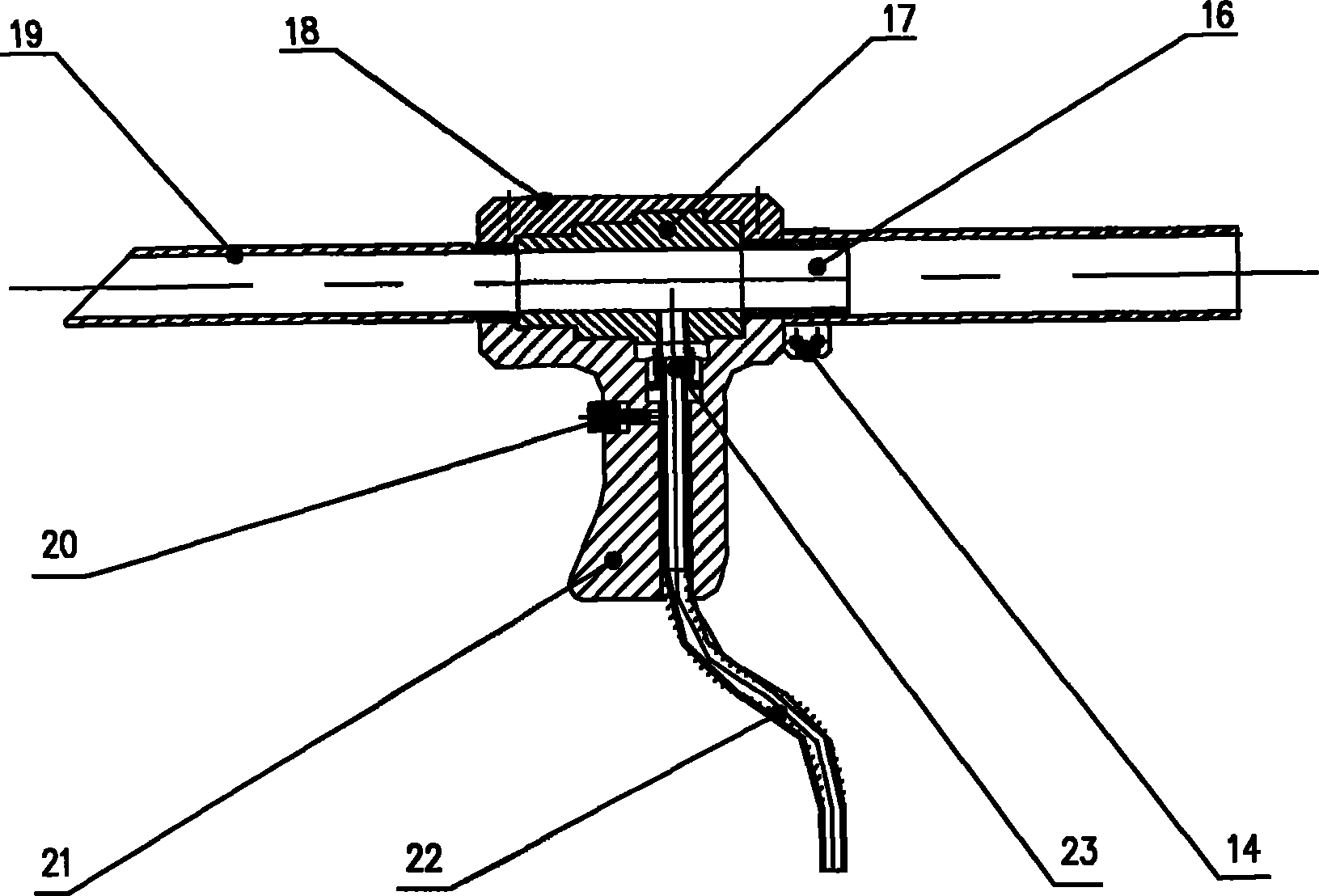

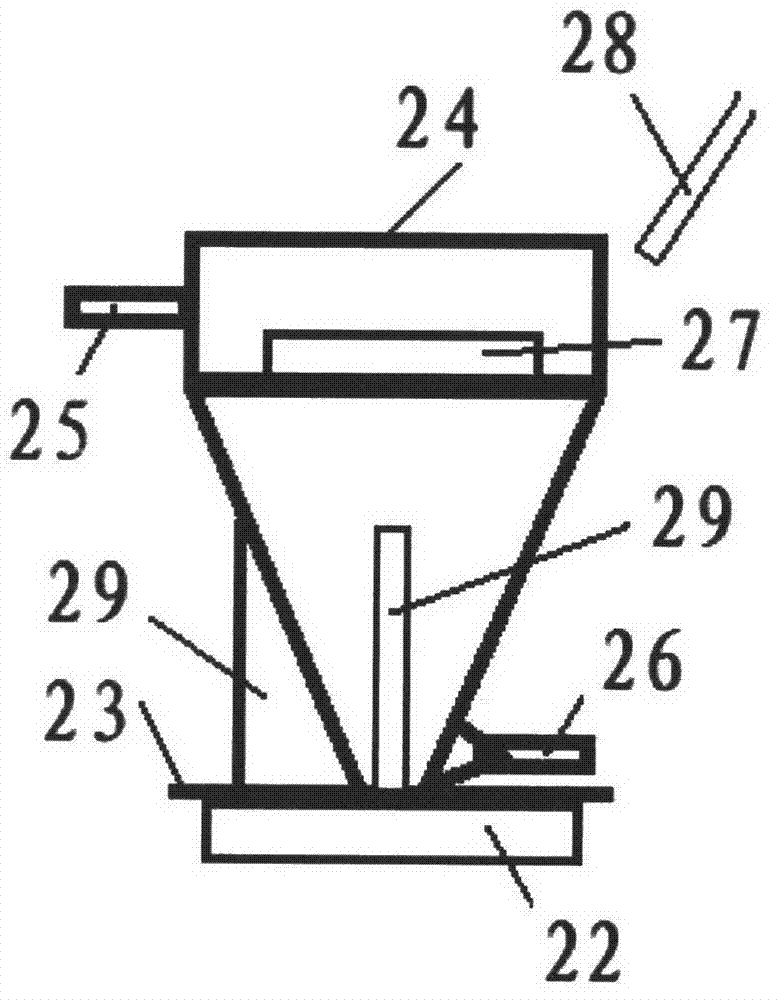

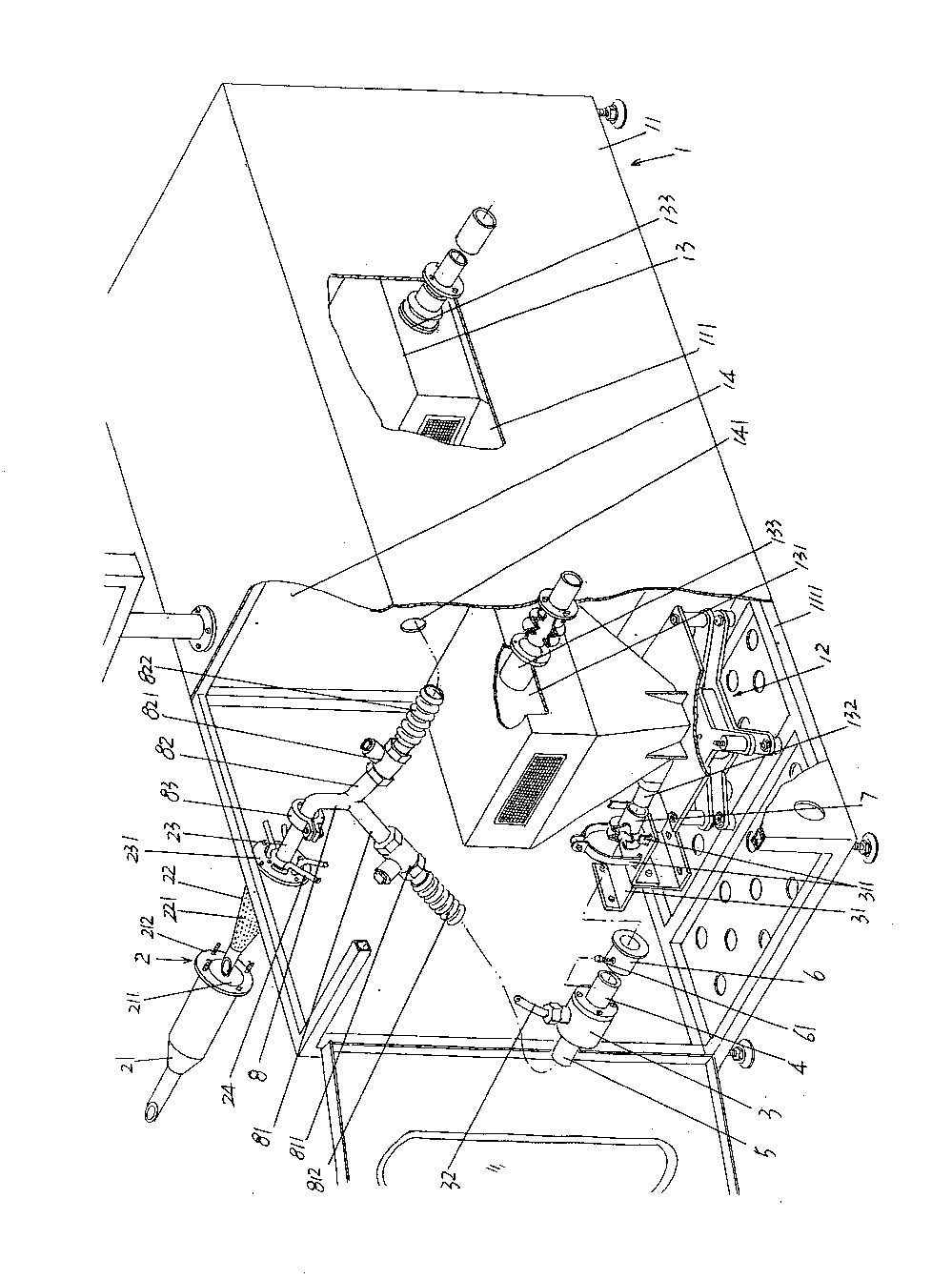

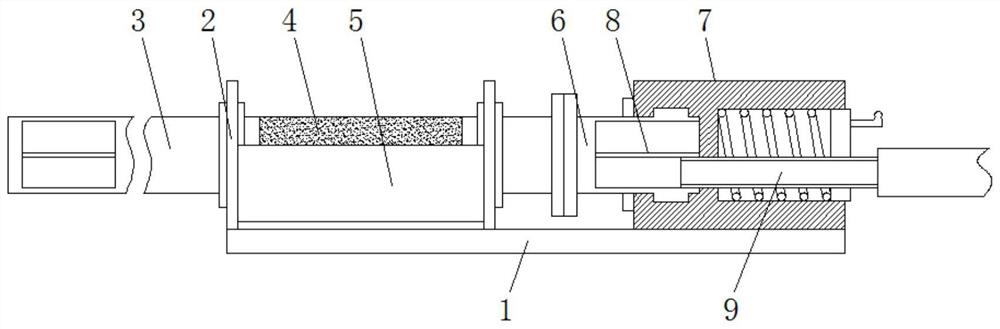

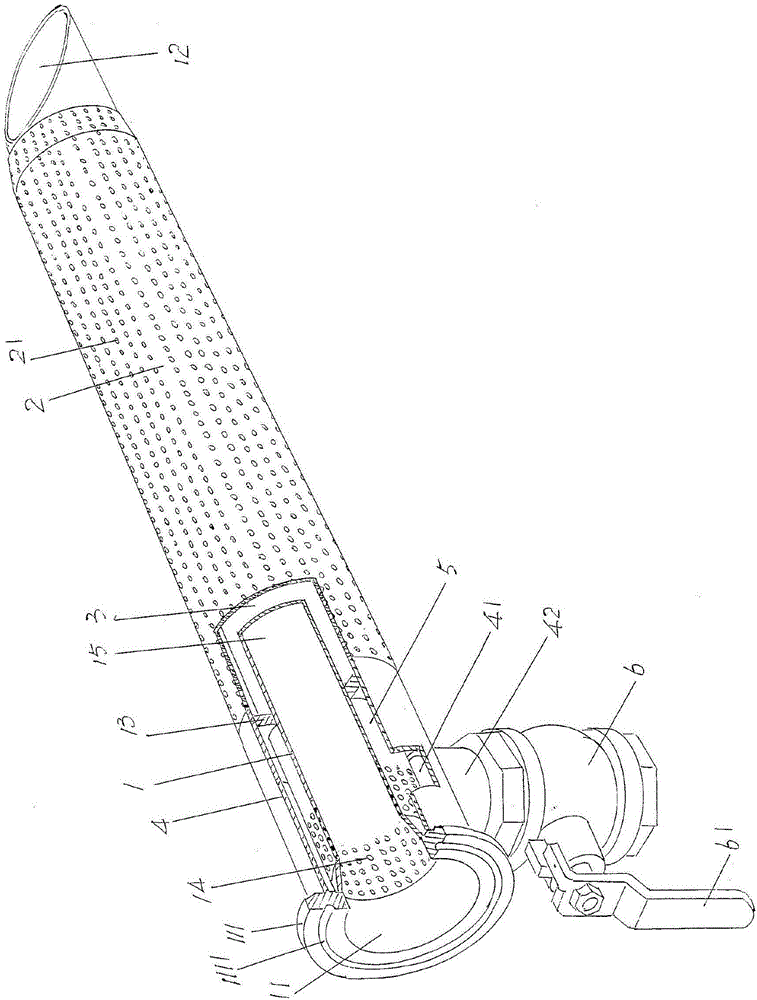

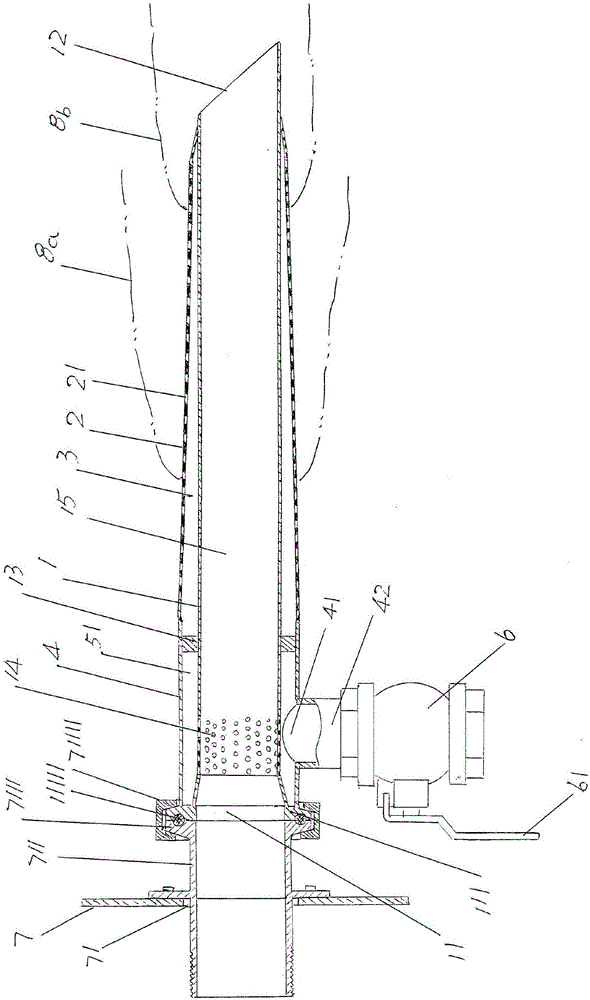

The invention relates to an automatic quantitative down-filling machine, which comprises a rack, a table surface, a balance, a down tube, a tube cover, an elbow, a hose, a down-filling gun and an automatic control device. The down-filling gun consists of a connecting pipe, an air amplifier, an air amplifier fixing cover, a down-filling pipe and a down-filling gun handle, the automatic control device comprises a down-filling switch, a weighing sensor, a single-chip microcomputer and a solenoid valve; the balance is arranged on the table surface, the down tube is supported on the balance by a bracket and is provided with a down-adding port, the hose is connected with the tube cover through the elbow, an elbow clamping block is fixed on a crossbeam, the down-filling gun is connected with the hose through the connecting pipe, the down-filling switch is arranged on the down-filling gun handle, an air intake pipe connector is connected with the air amplifier in the down-filling gun, and an air intake pipe penetrates through a hole on the down-filling gun handle and is connected with the air intake pipe connector. The invention has the advantages that the quantitative weighing and pneumatic filling of down are realized with the automatic control technology, the down-filing amount can be arbitrarily set, the filling efficiency is high, the working environment is good, and the down waste and damage can be reduced.

Owner:CHINA JILIANG UNIV

Down filling machine

InactiveCN103803476AAvoid the "white" problemReduce complexityUpholstery manufactureClothes making applicancesEngineeringCheck valve

The invention discloses a down filling machine. The down filling machine comprises a down storage box, a weighing box and a down discharge device, wherein down arranged in the down storage box is conveyed to the weighing box for weighing and output through a down outlet of the weighing box; the down discharge device comprises a down storage cavity, one end of the down storage cavity is a down outlet, an air pipe is arranged at the other end of the down storage cavity, a first port of the air pipe is connected with the down storage cavity through a filter, an air suction device is arranged at a second port of the air pipe, a valve is arranged between the air suction device and the first port of the air pipe, and an air blowing port is arranged between the valve and the first port of the air pipe and connected with an air conveying device; a down inlet is also arranged on the down storage cavity and connected with the down outlet of the weighing box through a check valve; and after the weighed down is input in the down storage cavity through large air flows, and the down in the down storage cavity is blown into clothed pieces through small air flows blown by the air blowing port, so that the problem of 'down exposure' caused by the large air flows is solved.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Down filling machine

ActiveCN102808245BEasy inputHigh outputUpholstery manufactureOakum treatmentEngineeringMechanical engineering

Owner:CHANGSHU BEALEAD AUTO MACHINERY

Efficient down filling machine

ActiveCN109607466AAvoid cakingImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringAir blower

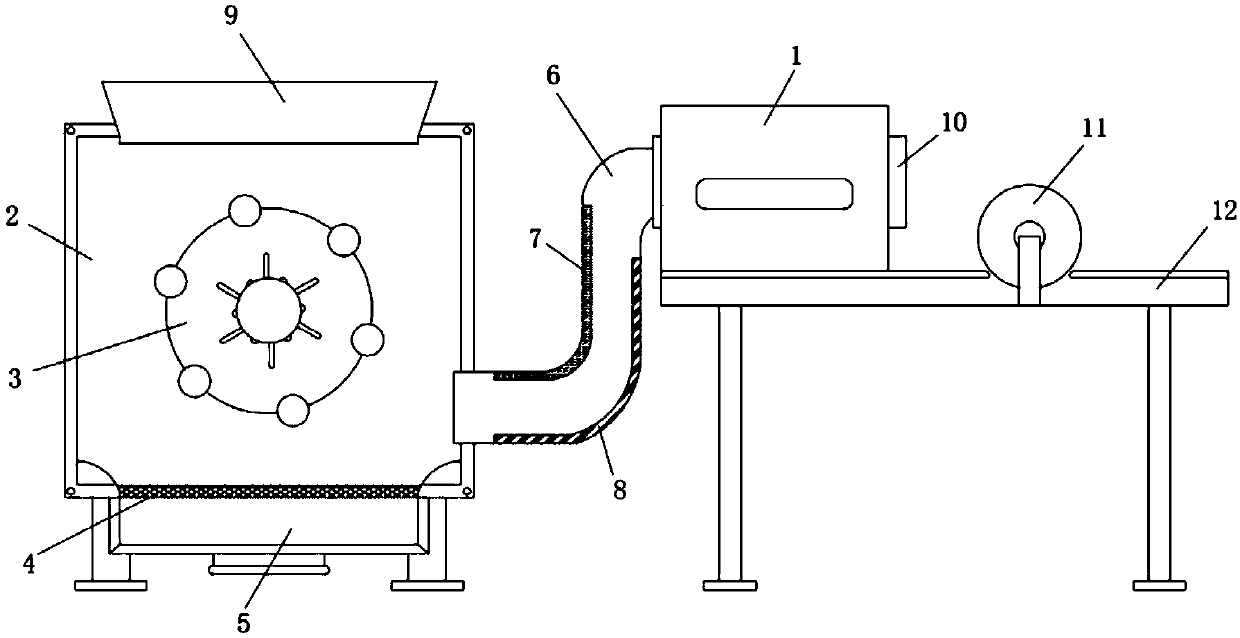

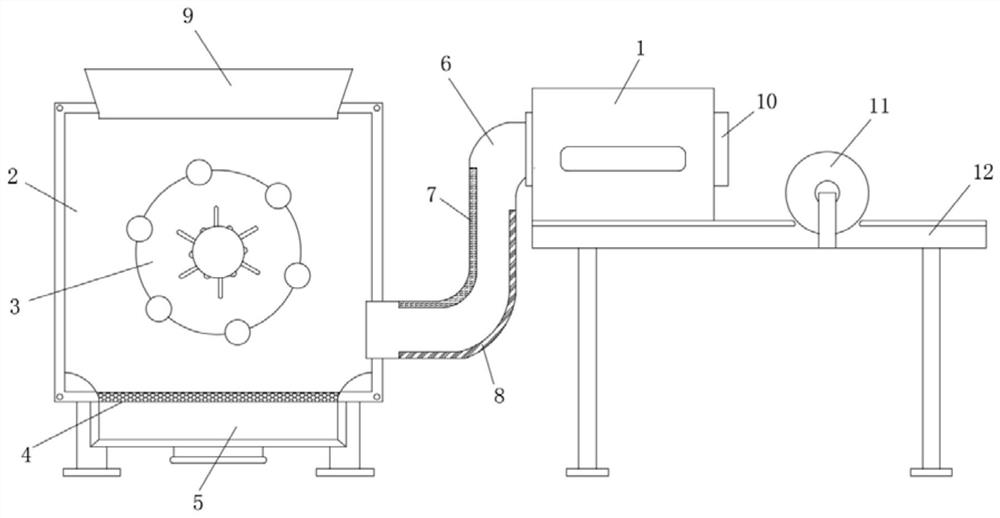

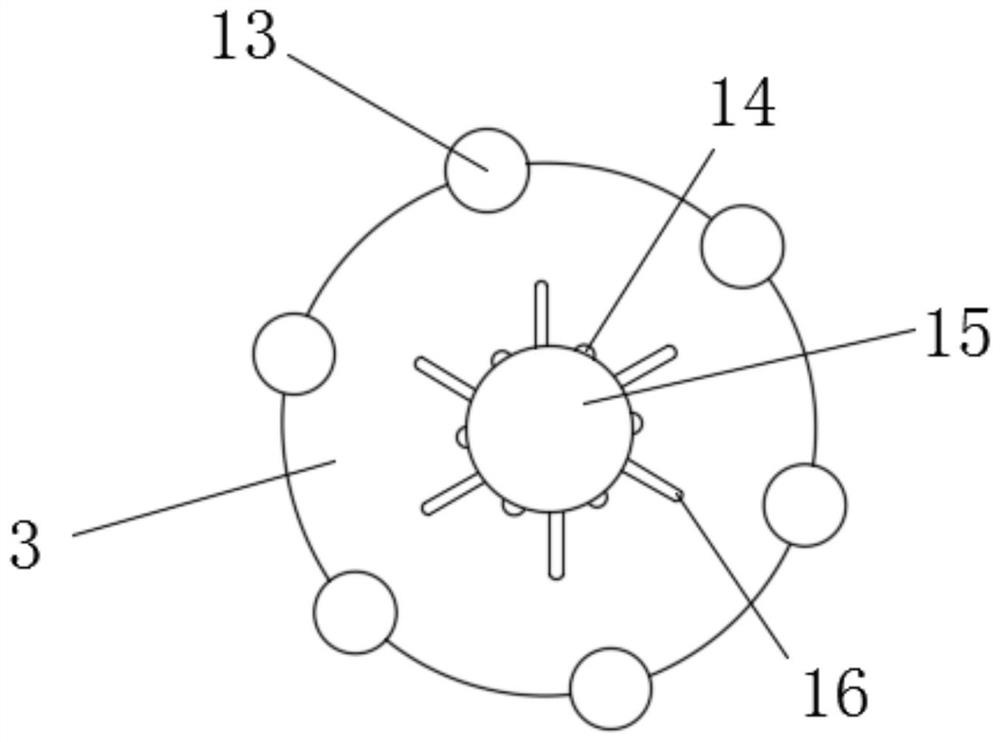

The invention discloses an efficient down filling machine which comprises a down filling machine main body, wherein a pipeline is mounted on one side of the down filling machine main body; a down filling port is formed in the other side of the down filling machine main body; a box body is mounted at one end of the pipeline; a down inlet is embedded into the upper part of the box body; a connectionround plate is arranged inside the box body; a rubber band is circumferentially arranged on the connection round plate; a connection pipe is embedded into the connection round plate. According to theefficient down filling machine, when the connection pipe rotates, the connection round plate is driven to rotate, so as to drive the rubber band and a short rod to rotate, and downs entering the boxbody can be flicked to avoid the hardening of the downs, scatter the downs and improve the down filling efficiency; when an air blower works, heat in a heating pipeline can be blown into the box bodythrough a through hole via an air blow pipe to play a very good air drying role and reduce moisture in the downs; an electric push rod controls a distance between a pressure plate and the down fillingport through a rotating shaft and a connection column so as to fix the down filling port and an object to be subjected to down filling.

Owner:颍上县祥盛建设管理有限公司

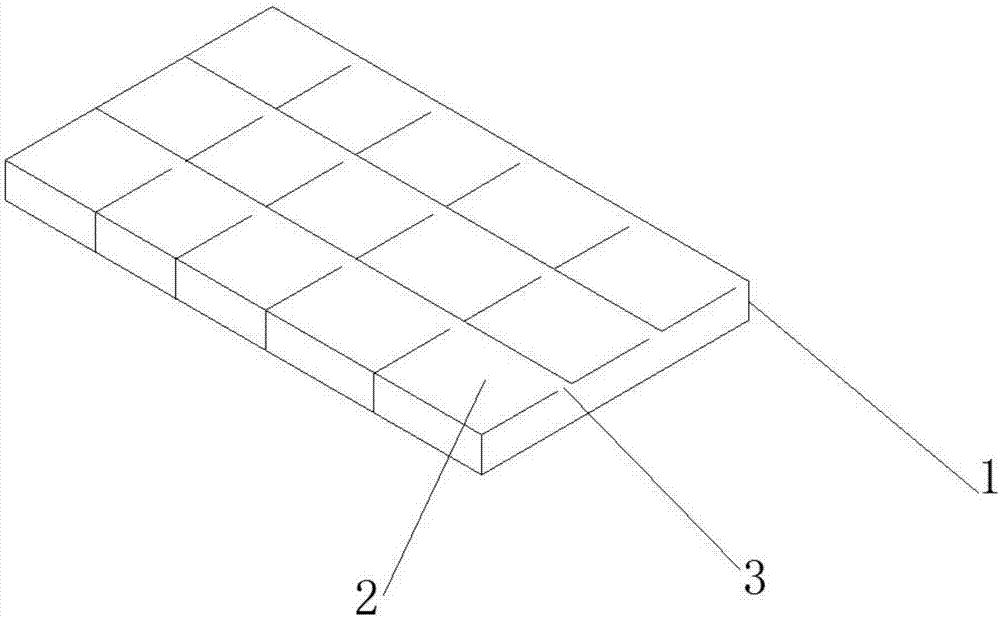

Duvet and down filling method thereof

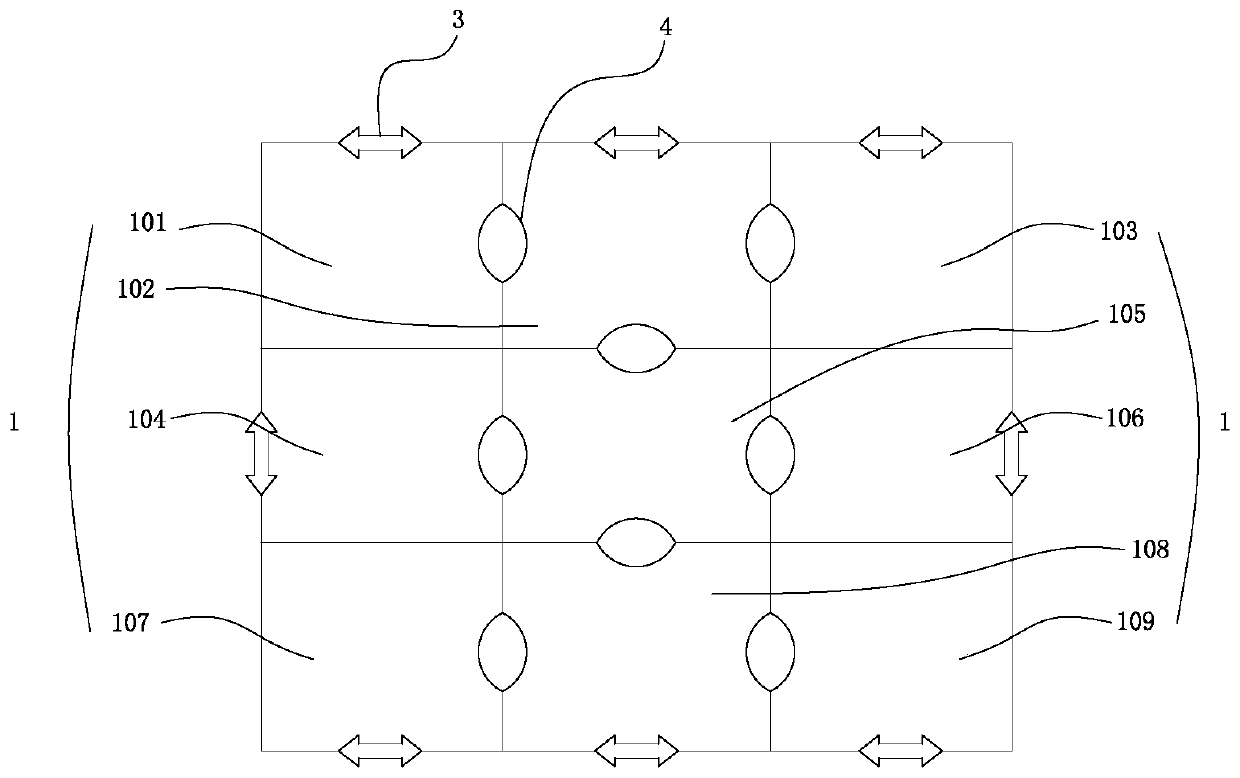

The invention provides a duvet including a quilt cover. After the quilt cover is symmetrically folded, the quilt cover is sewn together through needles and threads, the four sides of the upper surfaceof the quilt cover and the four sides of the lower surface of the quilt cover are sewn together through needles and threads, and a cavity is formed internally. The cavity is penetrated by needles andthreads from the upper surface of the quilt cover to the lower surface to form a plurality of square compartments, the end sides of the square compartments are provided with down filling ports, and the square compartments are longitudinally communicated through the down filling ports. By arrangement of a double-layer fabric, the down leakage caused by scratching can be effectively avoided, and the service life of the duvet is prolonged. Through the novel down filling method, the down filling can be more uniform, and the down filling efficiency of the duvet is greatly improved.

Owner:ANHUI LION GOOSE PROD

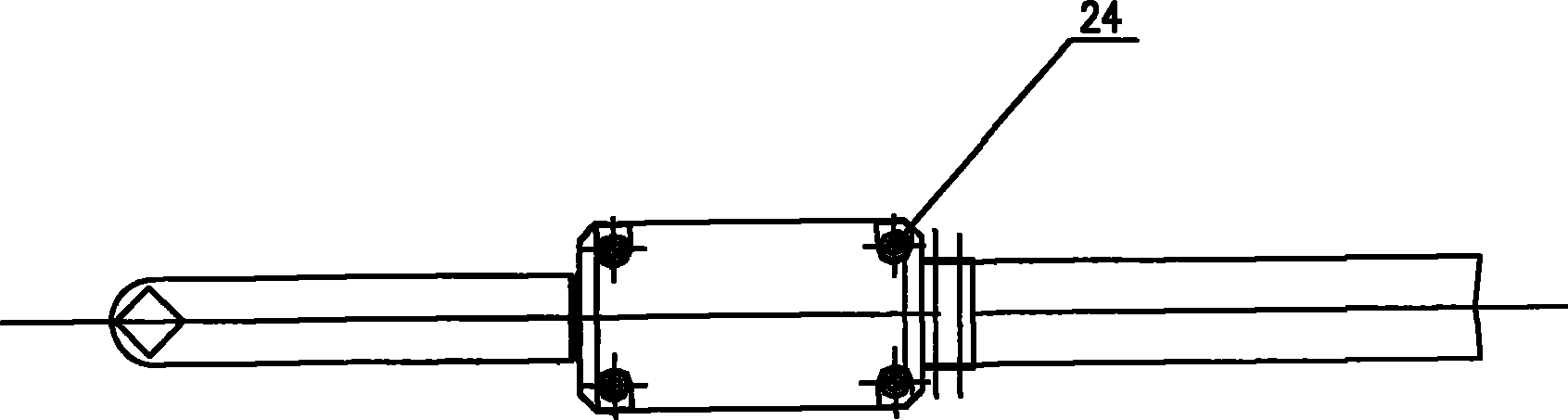

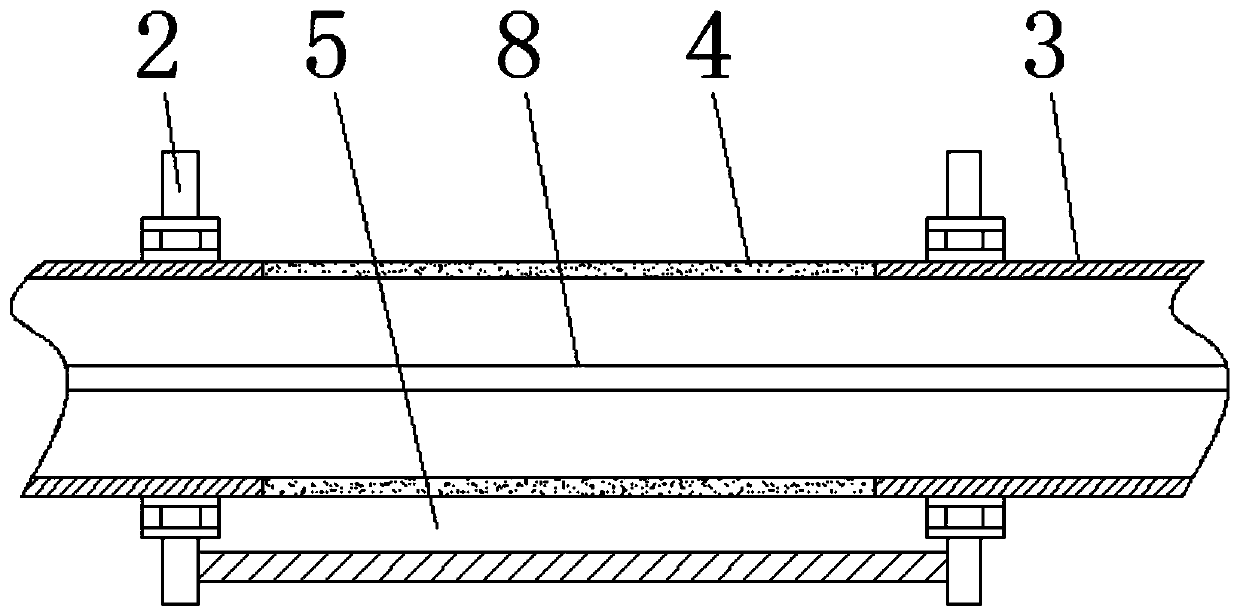

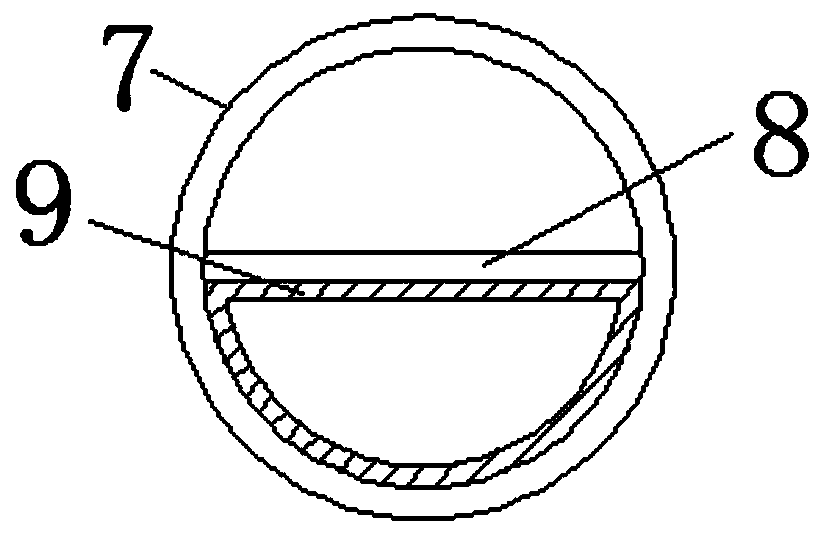

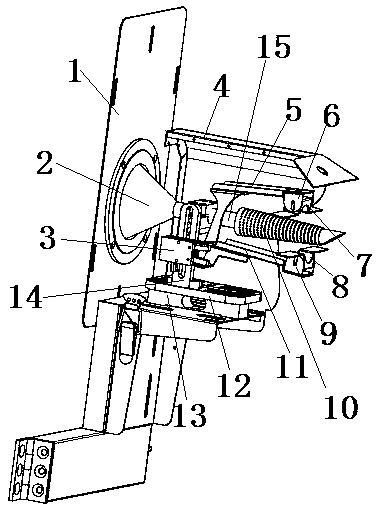

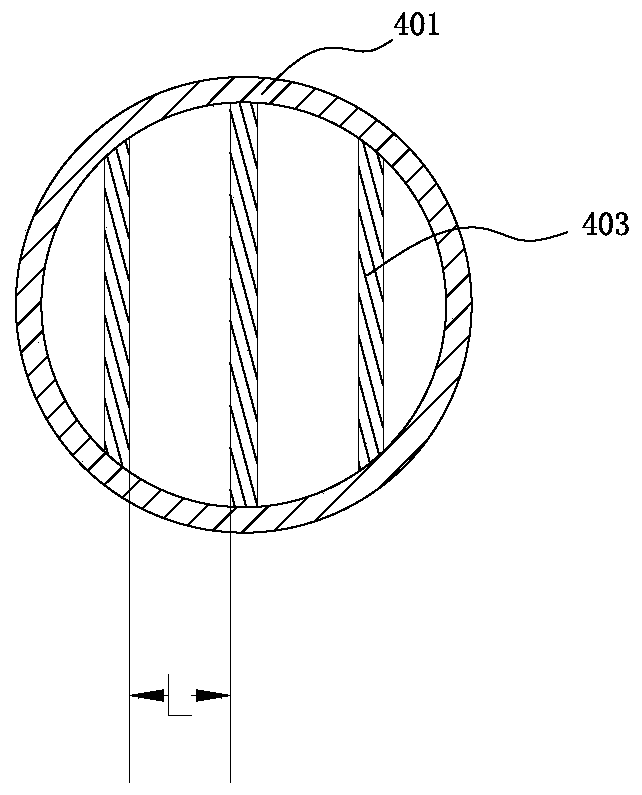

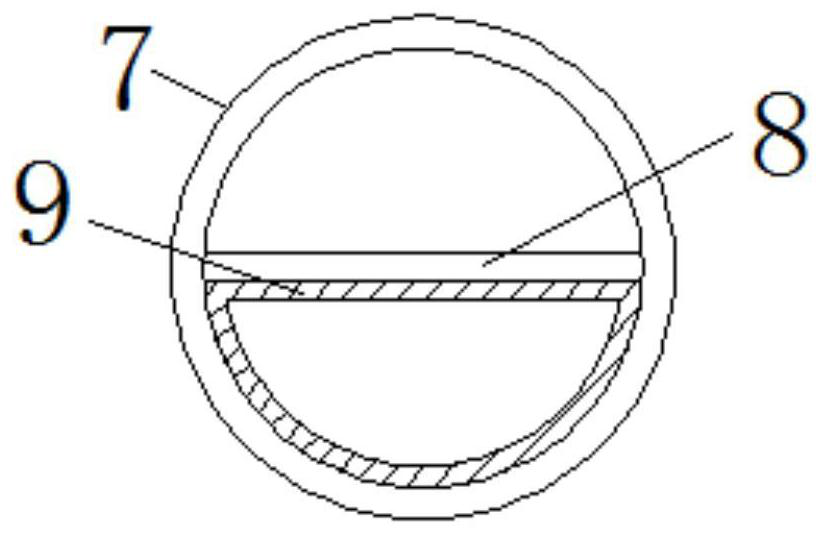

Down filling pipe assembly of down filling machine for down product production

ActiveCN110775935AImprove outflow efficiencyImprove down filling efficiencyUpholstery manufactureDispersed particle filtrationManufacturing engineeringMechanical engineering

The invention relates to the field of down product production and processing equipment, and discloses a down filling pipe assembly of a down filling machine for down product production. The down filling pipe assembly comprises a pipe base; one side of the top of the pipe base is fixedly connected with two limiting plates between which a rotatable down filling pipe is movably mounted in a sleeved manner; and the down filling pipe is provided with a full circle of filtering net located between the two limiting plates. According to the down filling pipe assembly of the down filling machine for down product production, the limiting plates, the down filling pipe, the filtering net, a packing sleeve, a linkage pipe, a control seat and a packing plate are arranged; in the down filling stage, downis injected from the lower space of the down filling pipe, air in a down product is discharged from the filtering net on one side of an upper half inner cavity of the down filling pipe, the filteringnet filters out the down mixed in the air, and the down is blown to the rightmost position of an upper half inner cavity of the linkage pipe under the effect of outflow of the air in the inner cavityof the down filling pipe, so that the down does not block the filtering net, the outflow efficiency of the air is improved, and the down filling efficiency is correspondingly improved.

Owner:济宁晨阳制衣股份有限公司

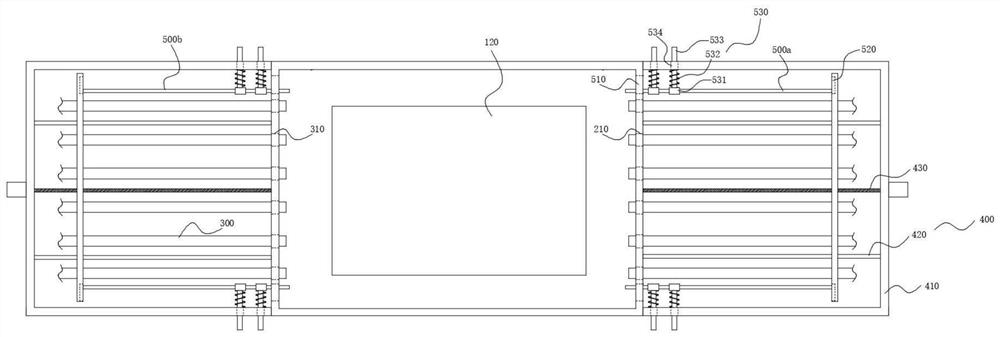

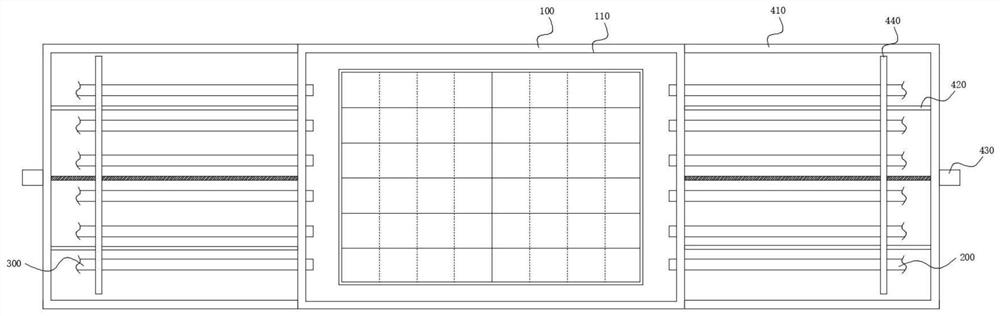

Working method of down filling machine

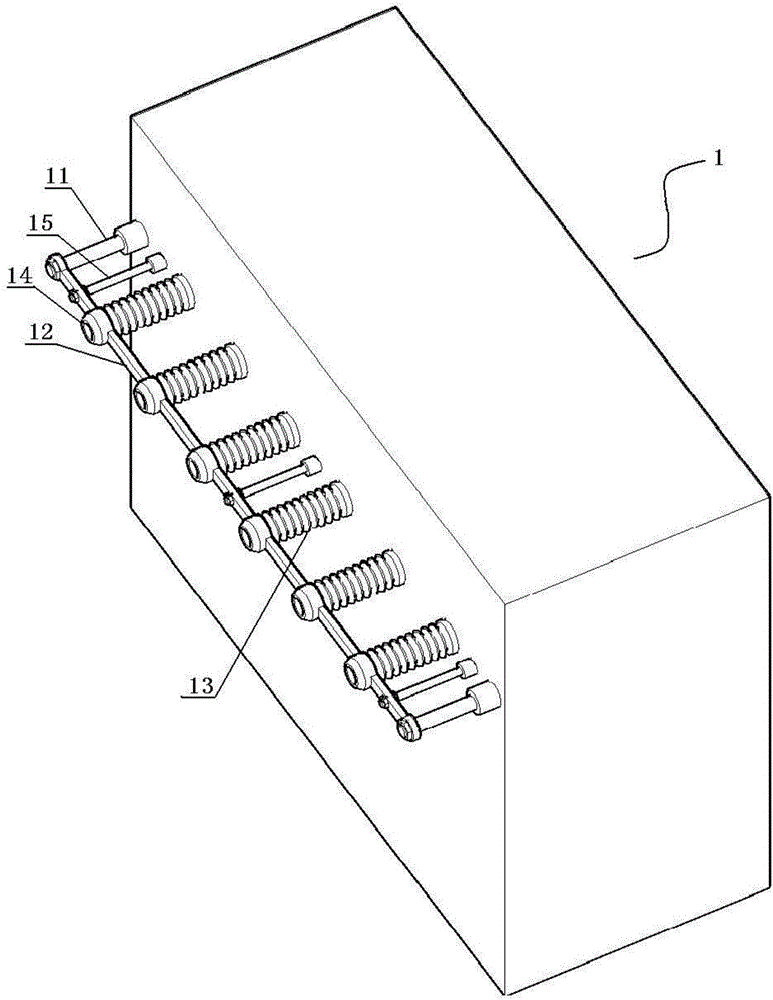

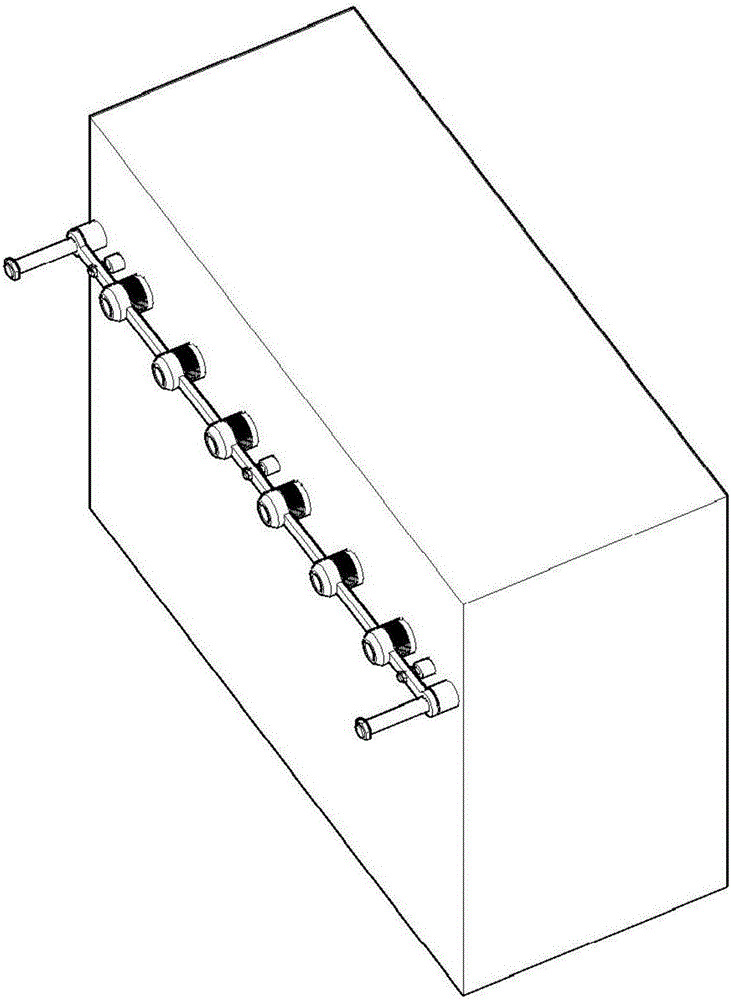

ActiveCN105936494AEven distribution of downImprove down filling efficiencyUpholstery manufactureThreaded pipeEngineering

Provided is a working method of a down filling machine. The two sides of one wall surface of a machine body are each provided with one guide rod. A supporting frame is arranged between the guide rods. Under the effect of external force, the supporting frame can axially move along the guide rods. A plurality of telescopic threaded pipes are arranged on the down filling machine. Each telescopic threaded pipe corresponds to one down filling pipe. A transverse or longitudinal row of cells can be filled with down at the same time, down filling efficiency and down filling speed are higher, and down of a down quilt can be easily and more uniformly distributed.

Owner:临沂高新物业管理有限公司

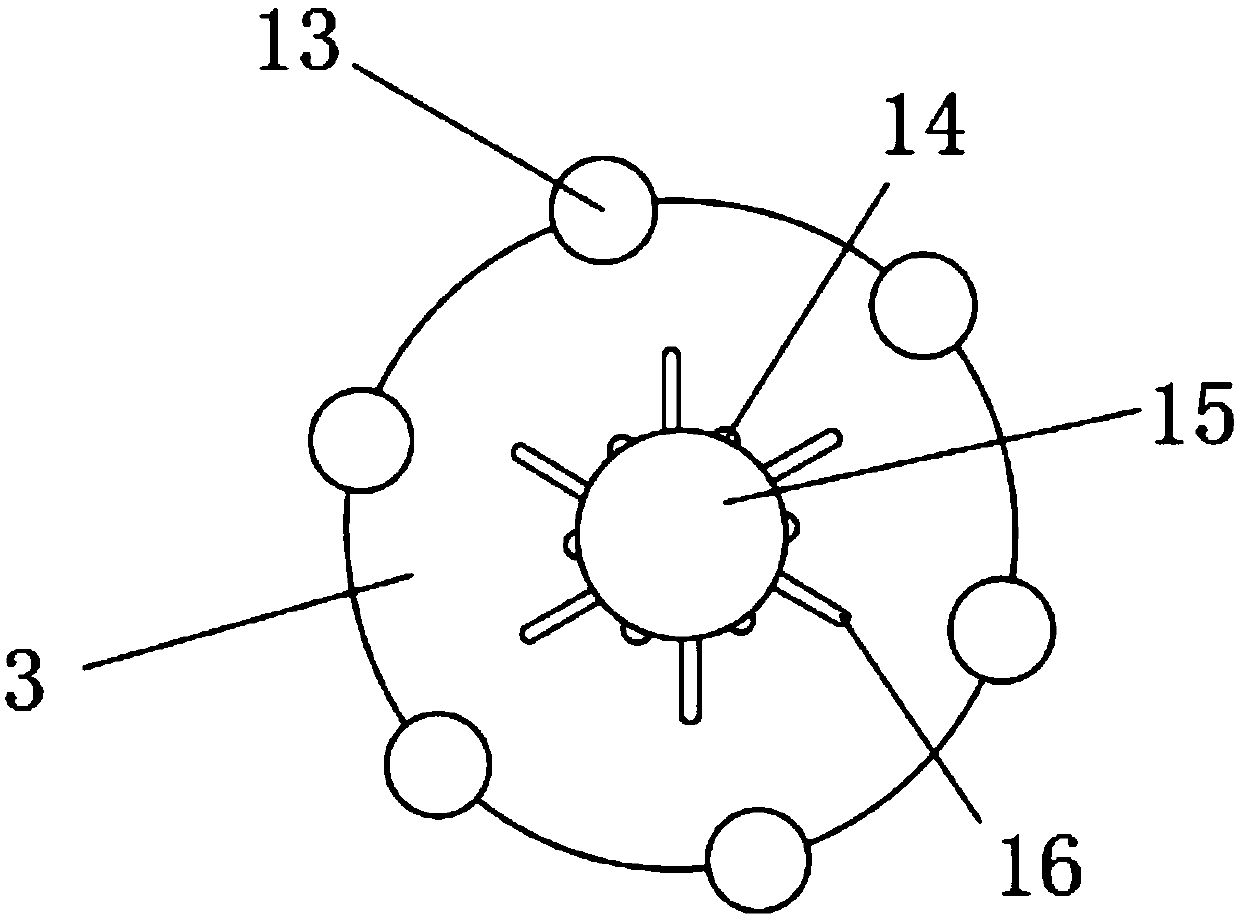

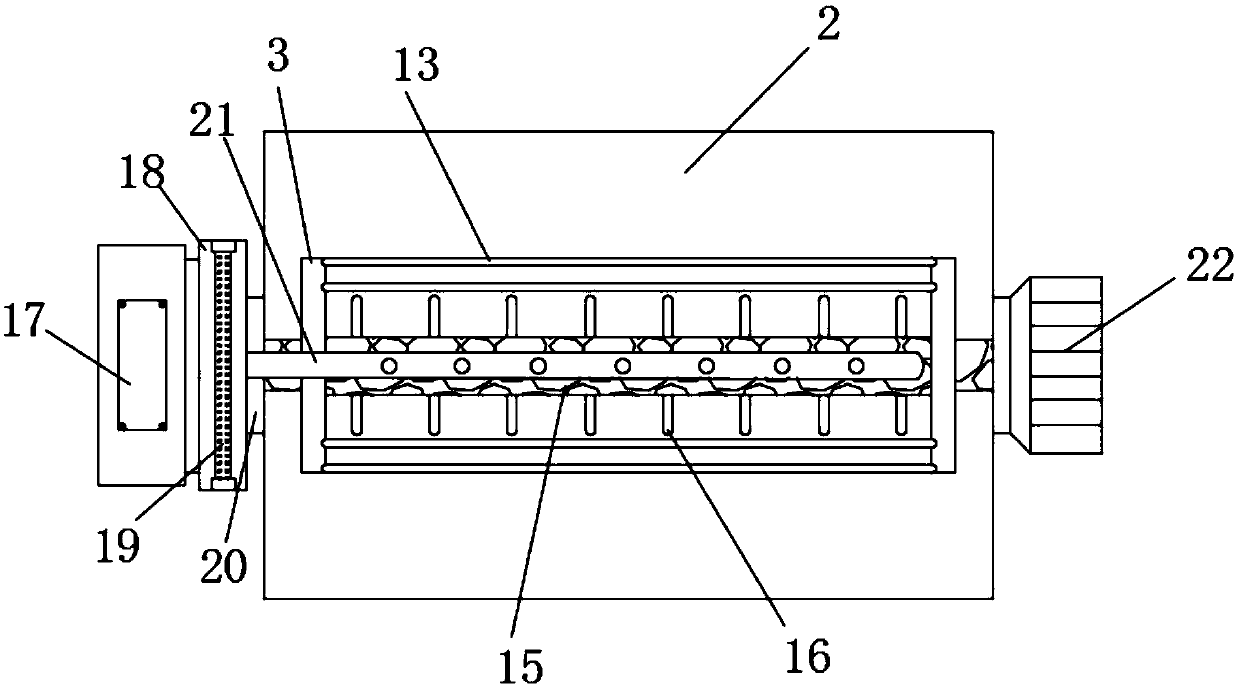

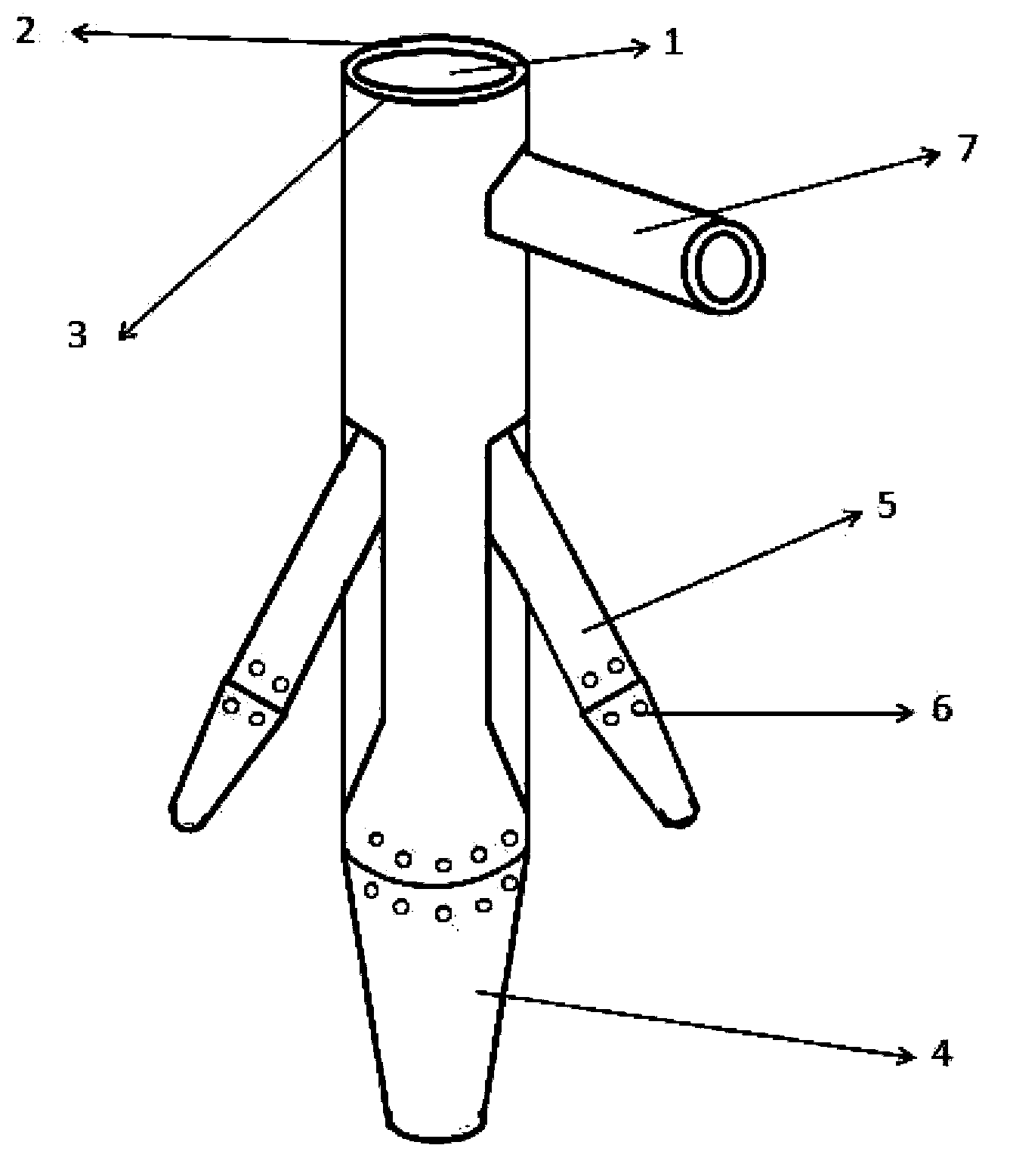

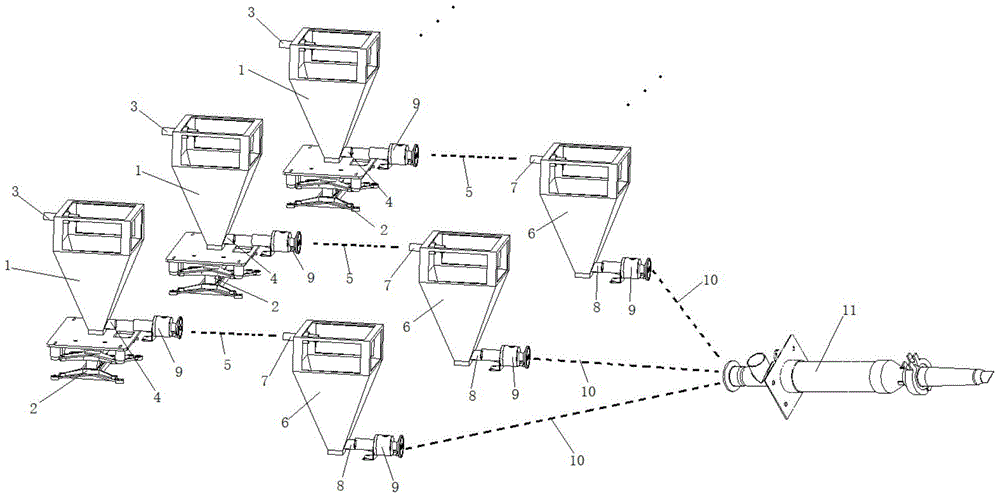

Down output mechanism of automatically quantitative down filling mechanism

ActiveCN103101874AMeet the down output requirementsImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringHigh pressure

The invention discloses a down output mechanism of an automatically quantitative down filling mechanism, and belongs to stowage equipment for down and feather filled products. The down output mechanism of the automatically quantitative down filling mechanism comprises a weighing counting mechanism, a down filling mechanism, a down inlet connector, a down outlet port and a down lead-out pipe. The weighing counting mechanism comprises a weighing box body, a weighing device and a weighing hopper. The down filling mechanism is characterized by comprising a pneumatic transmission device, the pneumatic transmission device is connected with one end of a high pressure air pipe of the pneumatic transmission device in a matched mode, and the other end of the high pressure air pipe of the pneumatic transmission device is connected with a pipeline of a high pressure air generator. The down inlet port is connected with one side of a down inlet of the pneumatic transmission device in a matched mode, and the down outlet port is connected with one side of a down outlet of the pneumatic transmission device in a matched mode. One end of a pipe sleeve is fixed on the down inlet port, the other end of the pipe sleeve is elicited out of the down inlet port, and a flexible suction plate sleeve is placed on a down outlet pipe of the weighing hopper in a sleeved mode. One end of the down lead-out pipe is connected with the down filling mechanism, a first branch pipe and a second branch pipe are formed by the other end of the down lead-out pipe, a first one-way valve, a second one-way valve, a first down through pipe and a second through pipe are placed on the first branch pipe and the second branch pipe. The down output mechanism of the automatically quantitative down filling mechanism has the advantages of meeting demands for down outputting of two weighing hoppers and being high in down filling efficiency.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Down/cotton filling machine

PendingCN108545690AImprove down filling efficiencyGuaranteed accuracyUpholstery manufactureClothes making applicancesSmall footprintLoad cell

The invention discloses a down / cotton filling machine. The down / cotton filling machine comprises a weighing assembly arranged on the outer wall of a machine body; the weighing assembly comprises a weighing sensor, a bearing plate is installed on the weighing sensor, and the weighing sensor is used for sensing the sum of mass of the bearing plate and objects on the bearing plate; a filling head isinstalled on the bearing plate through a support and used for receiving airflow carrying down / cotton jetted out of a lower bin body of the machine body; an electromagnetic valve is arranged on the filling head, a PLC control mechanism is connected to the electromagnetic valve and connected with the weighing sensor, and a clamping mechanism for clamping a to-be-filled part and the filling head is arranged on the filling head. The down / cotton filling machine has the advantages of being capable of guaranteeing the precision of mass of filling down / cotton, and high in down / cotton filling efficiency; moreover, the down / cotton filling machine is simple in structure, convenient to maintain, small in occupied space and low in price.

Owner:常熟市荣康电子科技有限公司

Folding down filling pipe used on full-automatic down filling machine

InactiveCN103896202AReduce wasteImprove uniformityUpholstery manufactureClothes making applicancesMechanical engineering

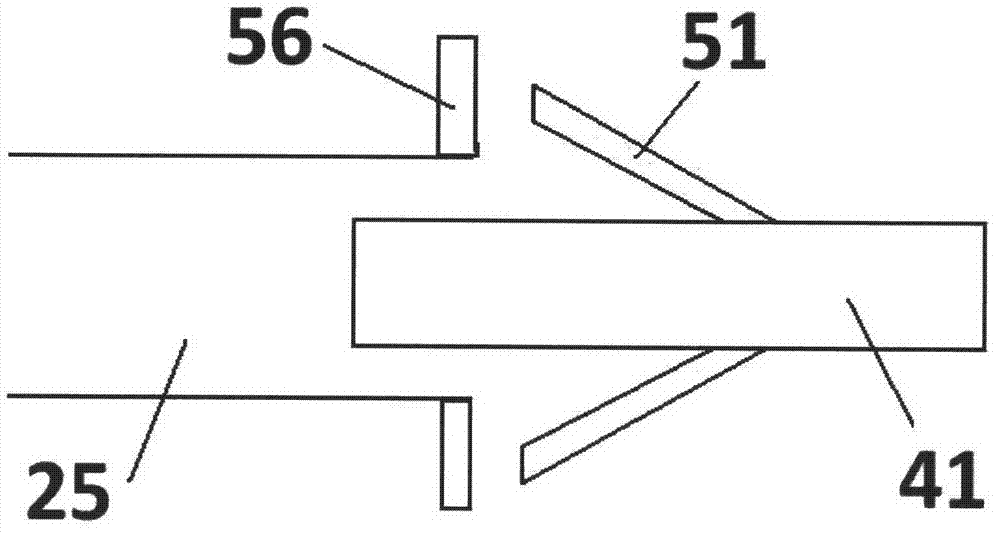

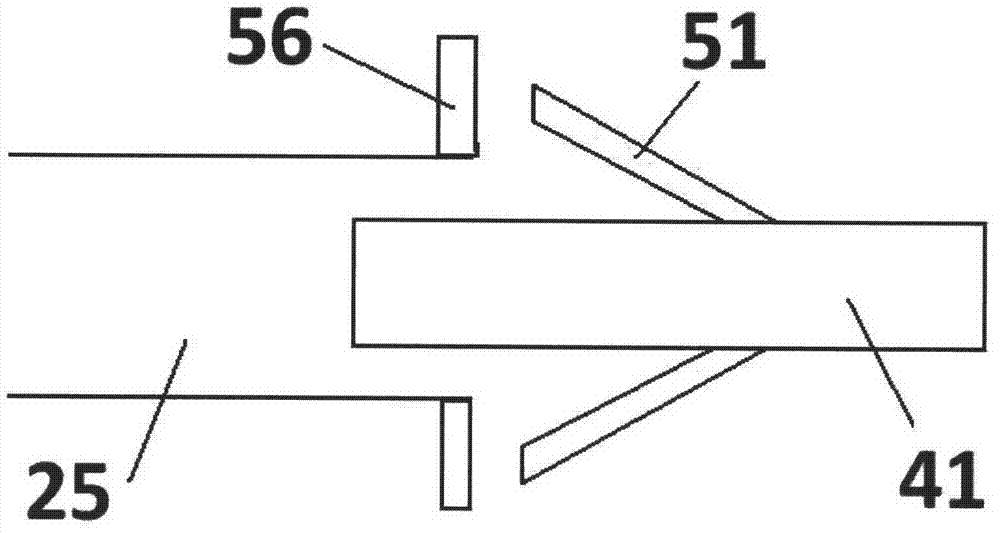

The invention provides a folding down filling pipe used on a full-automatic down filling machine. The folding down filling pipe is characterized by comprising a main down filling pipe body, auxiliary down filling pipe bodies and a collecting branch pipe, the two auxiliary down filling pipe bodies are located on the two sides of the main down filling pipe body respectively, the roots of the auxiliary down filling pipe bodies and the main down filling pipe body are fixed through shafts, and the collecting branch pipe is located at the rear end of the main down filling pipe body. The folding down filling pipe used on the full-automatic down filling machine has the advantages of being simple in structure, convenient to install and use and high in working efficiency.

Owner:TIANJIN SUNSHINE ERIC CONTROL EQUIP

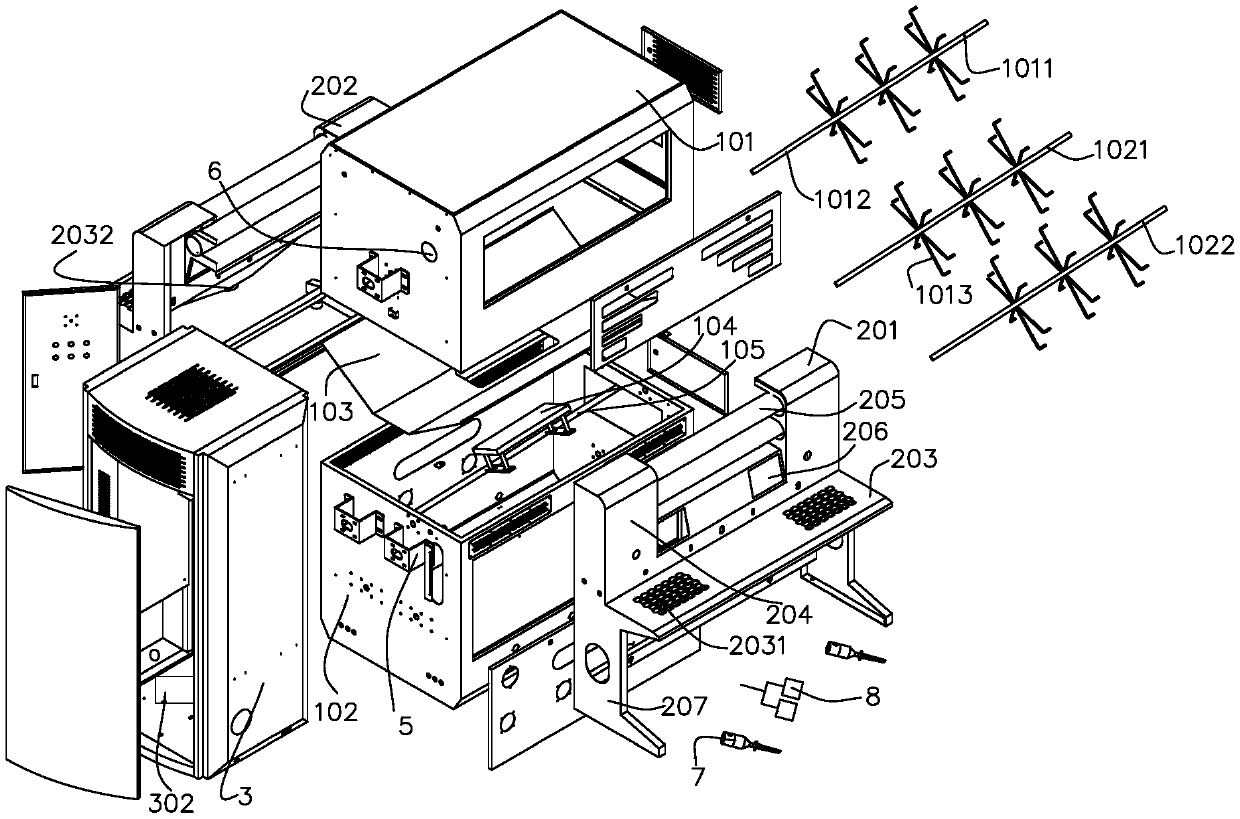

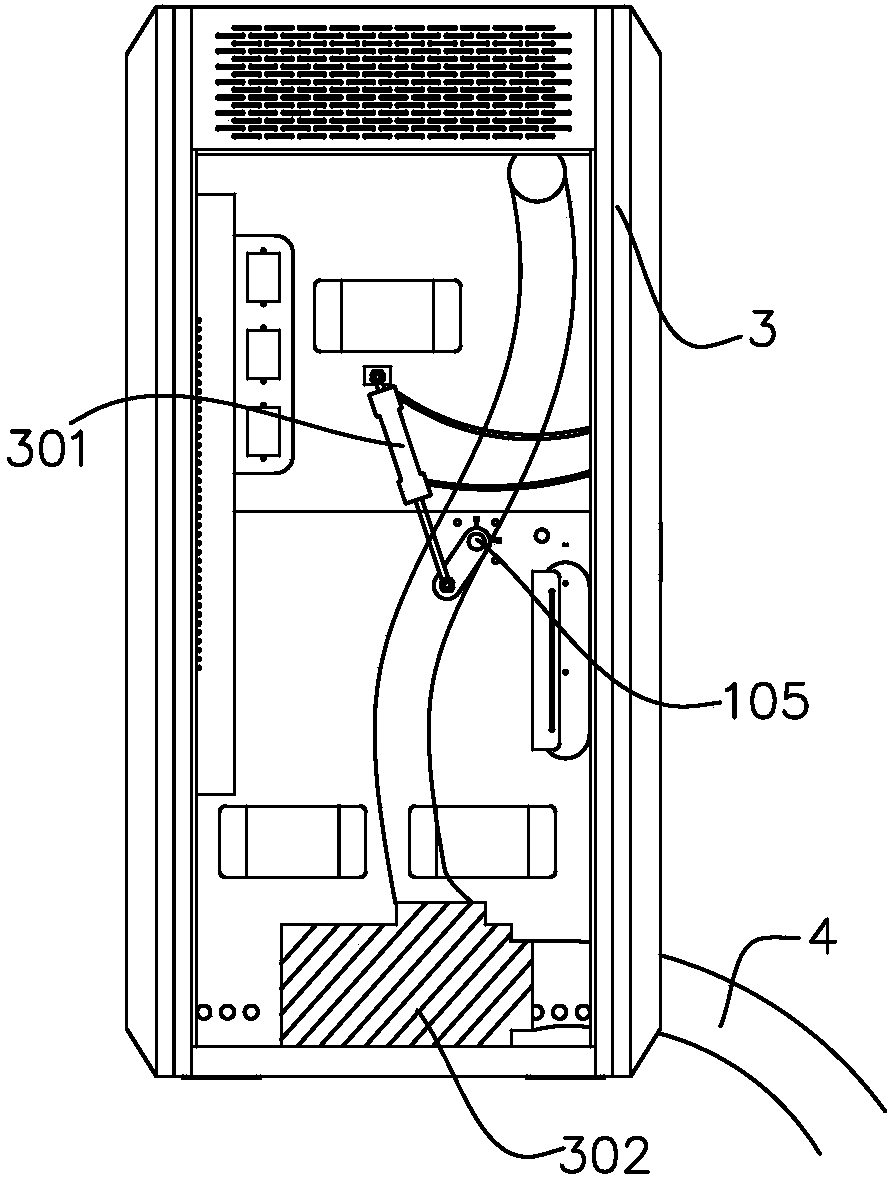

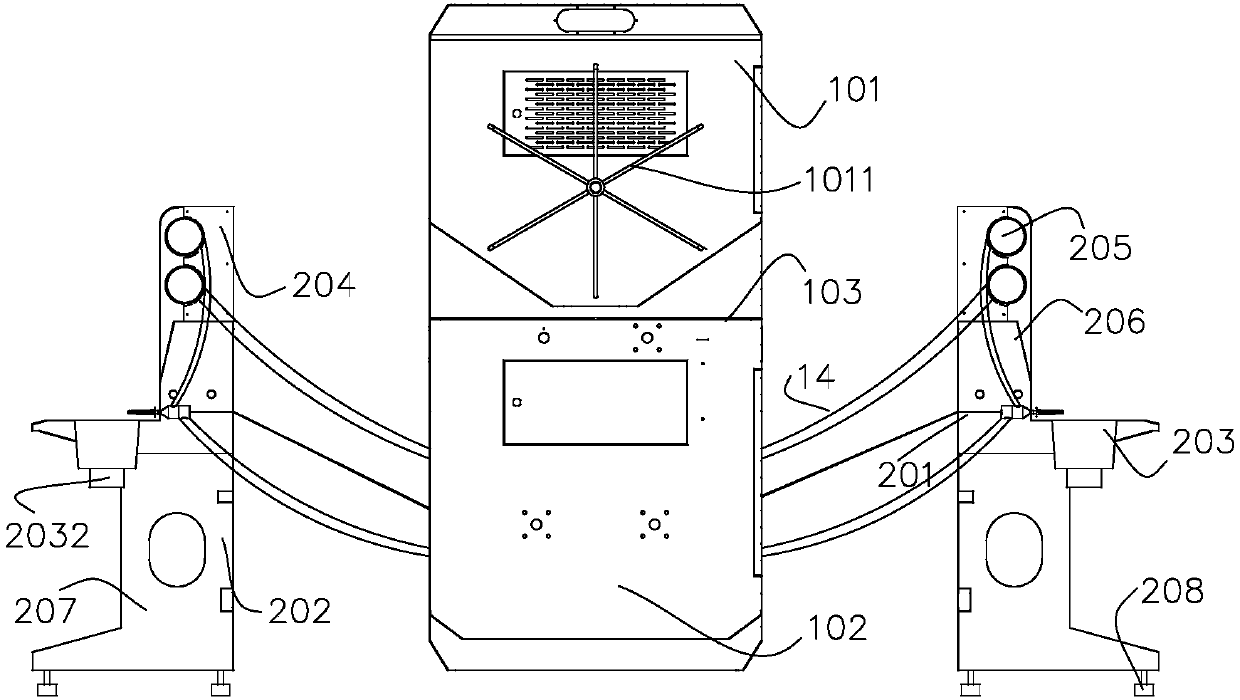

Down filling machine

PendingCN107758602AImprove down filling efficiencyEasy to observe statusUpholstery manufactureSolenoid valveDisplay device

The invention provides a down filling machine. The down filling machine comprises a main box body and two down filling platforms, wherein the two down filling platforms comprises a main down filling platform and a vice down filling platform, and the two down filling platforms are symmetrically arranged on the two sides of the main box body; the main box body of the down filling machine is dividedinto an upper box body and a lower box body, and the upper box body and the lower box body are respectively provided with a stirrer which is driven by a drive motor and thoroughly stirs down feather;the down filling platform comprises a rectangle operating platform, a down filling support is arranged on the upper side of the operating platform, an organic glass pipe and a display are installed onthe down filling support, one end of the organic glass pipe is communicated with a down filling gun, and the other end of the organic glass pipe is communicated with the lower box body through a downtransmitting soft pipe; in cooperation with the down filling gun, an air pipe and an electromagnetic valve, the organic glass pipe is controlled by a PLC, down filling efficiency is improved, and costs are reduced. The down filling machine is capable of reducing labor strength, improving production efficiency, and reducing costs. The down filling machine is simple in structure, reasonable in design, and strong in practicability.

Owner:上海推罗智能设备科技有限公司

Down quilt with good down locking effect and down filling method thereof

PendingCN110192749AImprove uniformityQuality improvementUpholstery manufactureBlanketEngineeringHot-melt adhesive

The invention provides a down quilt with a good down locking effect. An inner cavity is formed in an upper quilt cover and a lower quilt cover. The inner cavity is penetrated by needles and threads from the upper quilt surface to the lower quilt surface to form a plurality of first compartments. A first down filling opening is formed in the end side of each first compartment. The first compartments are communicated with one another through a down filling bag. The down filling bag comprises upper supporting cloth and lower supporting cloth. The upper supporting cloth and the lower supporting cloth are bonded to the inner wall of the inner cavity through a hot melt adhesive. The upper supporting cloth and the lower supporting cloth are both hard U-shaped cloth. The two sides of the upper supporting cloth and the two sides of the lower supporting cloth are bonded through the hot melt adhesive. A down filling channel is defined by the upper supporting cloth and the lower supporting cloth.A plurality of pieces of swingable blocking cloth are bonded to the inner upper wall of the down filling channel through the hot melt adhesive. The invention further provides a down filling method ofthe down quilt with the good down locking effect. According to the invention, the down locking effect of the down quilt can be effectively improved. The down in the down quilt is prevented from movingdisorderly. The down in the down quilt is evenly distributed. The down filling efficiency and the down filling quality are effectively improved.

Owner:杭州华隆羽绒制品有限公司

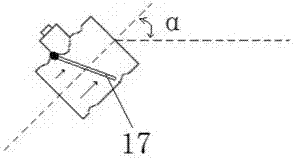

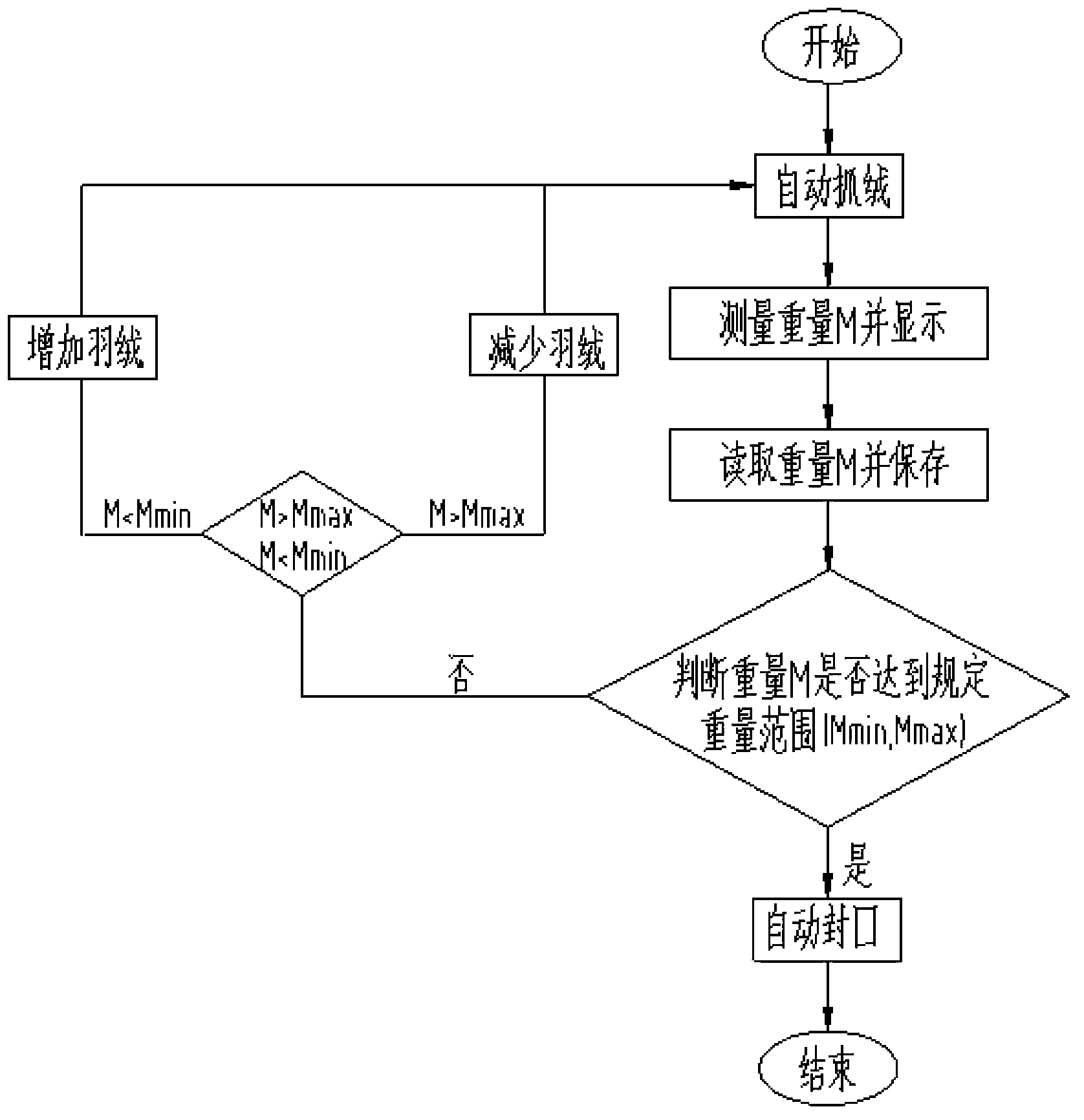

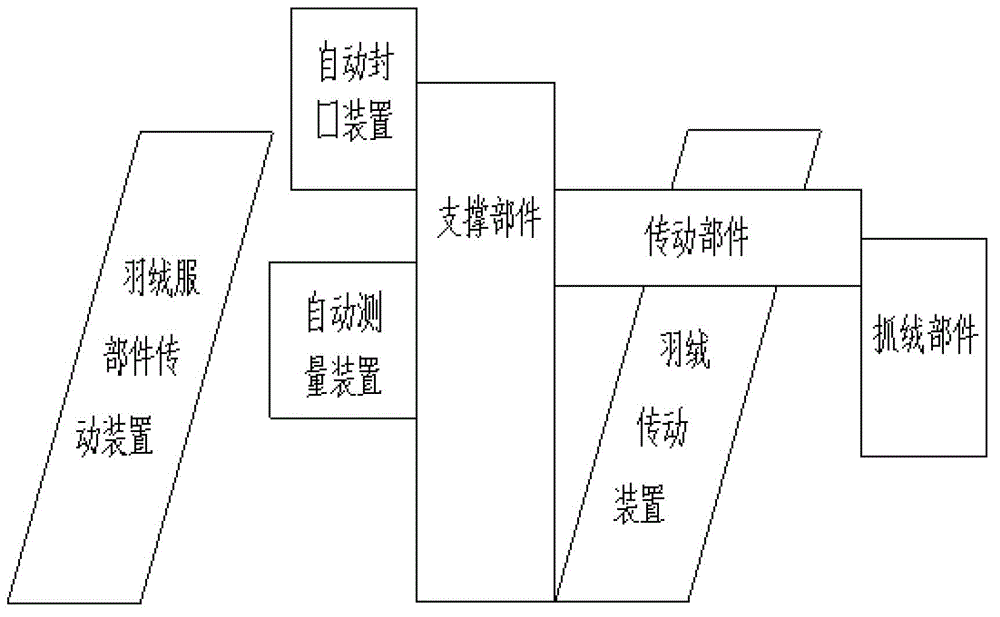

Automatic down filling method and automatic down filling equipment

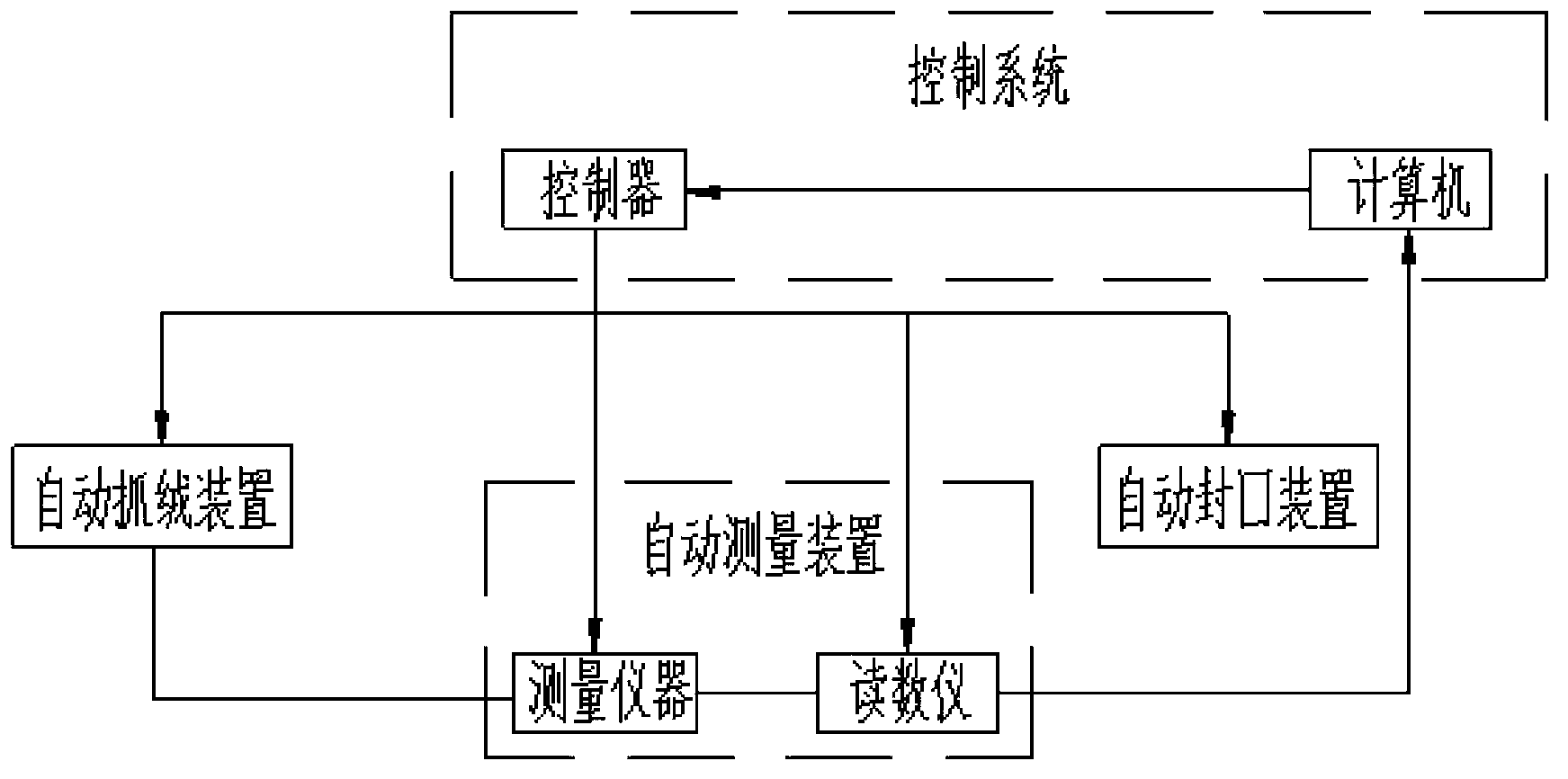

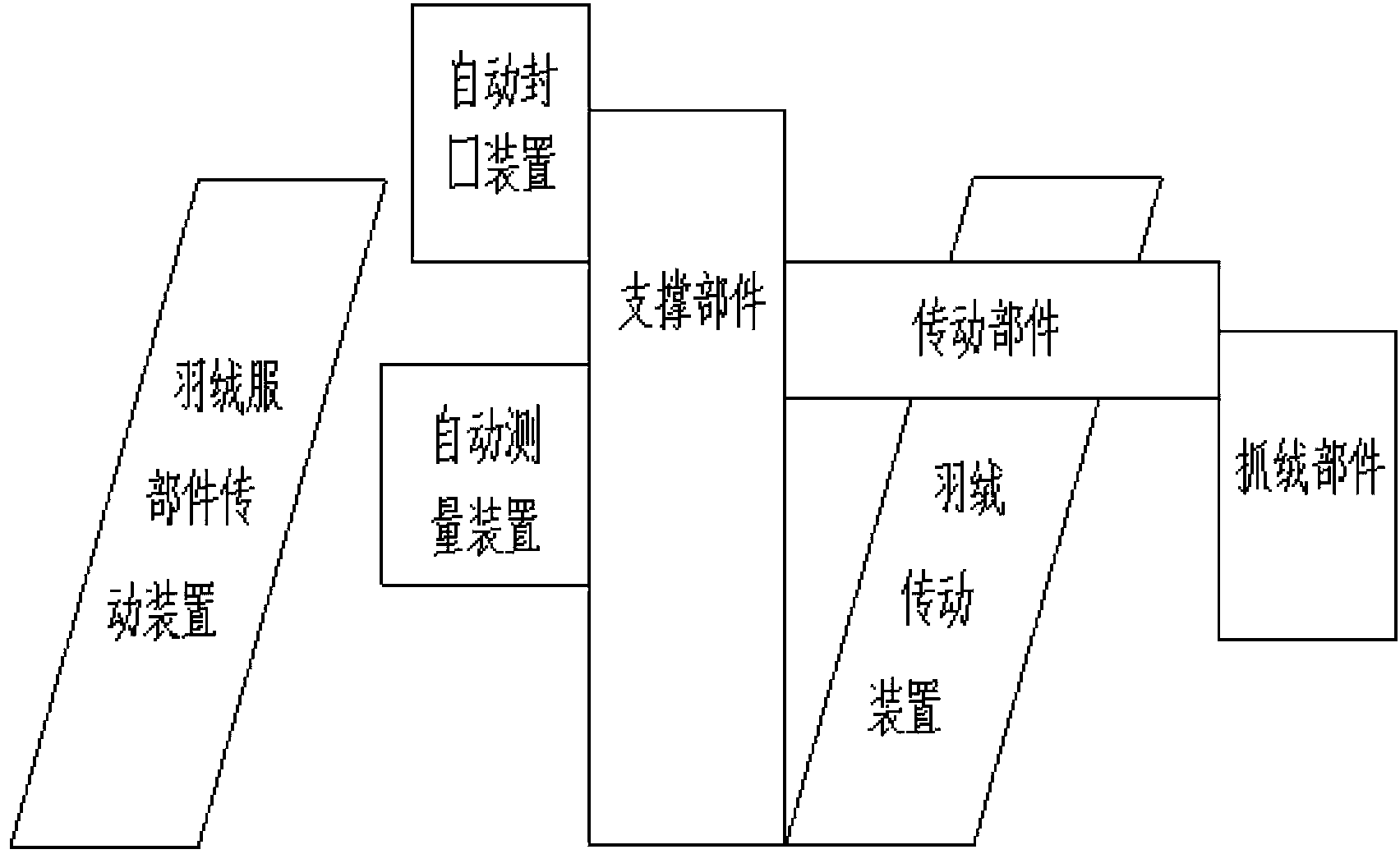

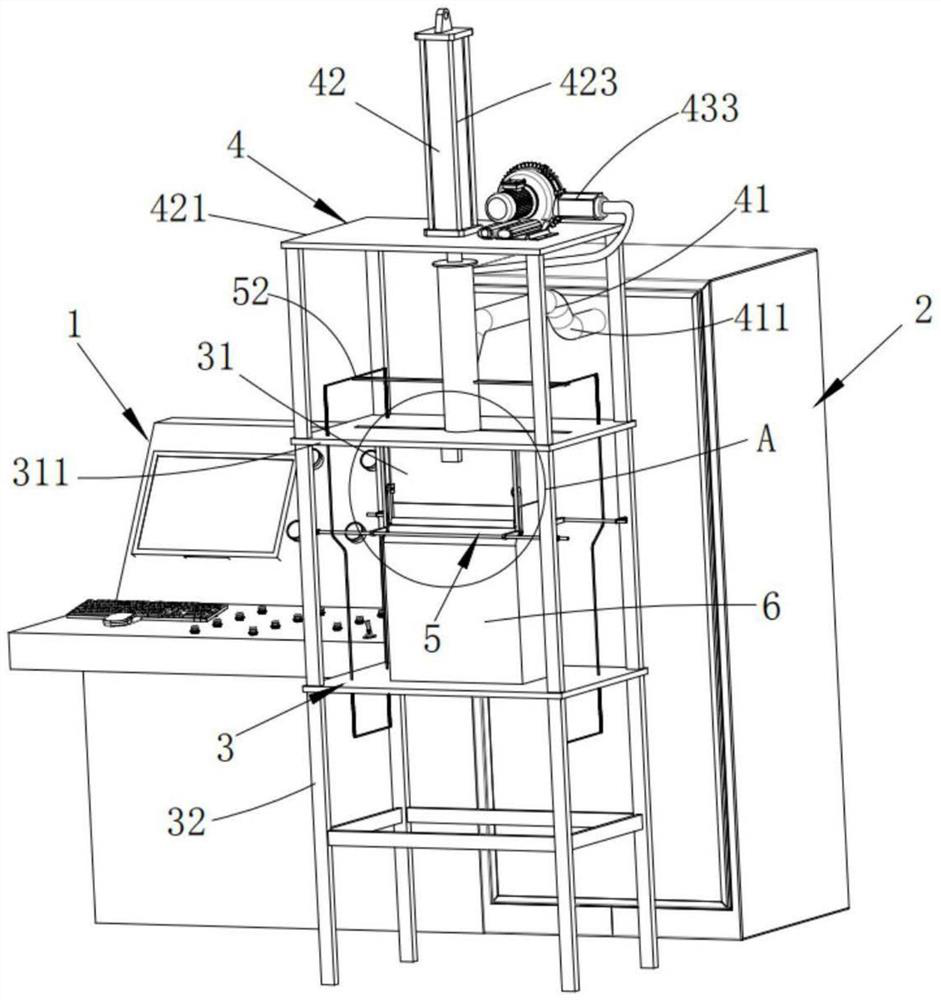

InactiveCN103844423AReduce labor intensityReduce the chance of diseaseClothes making applicancesMeasurement deviceControl system

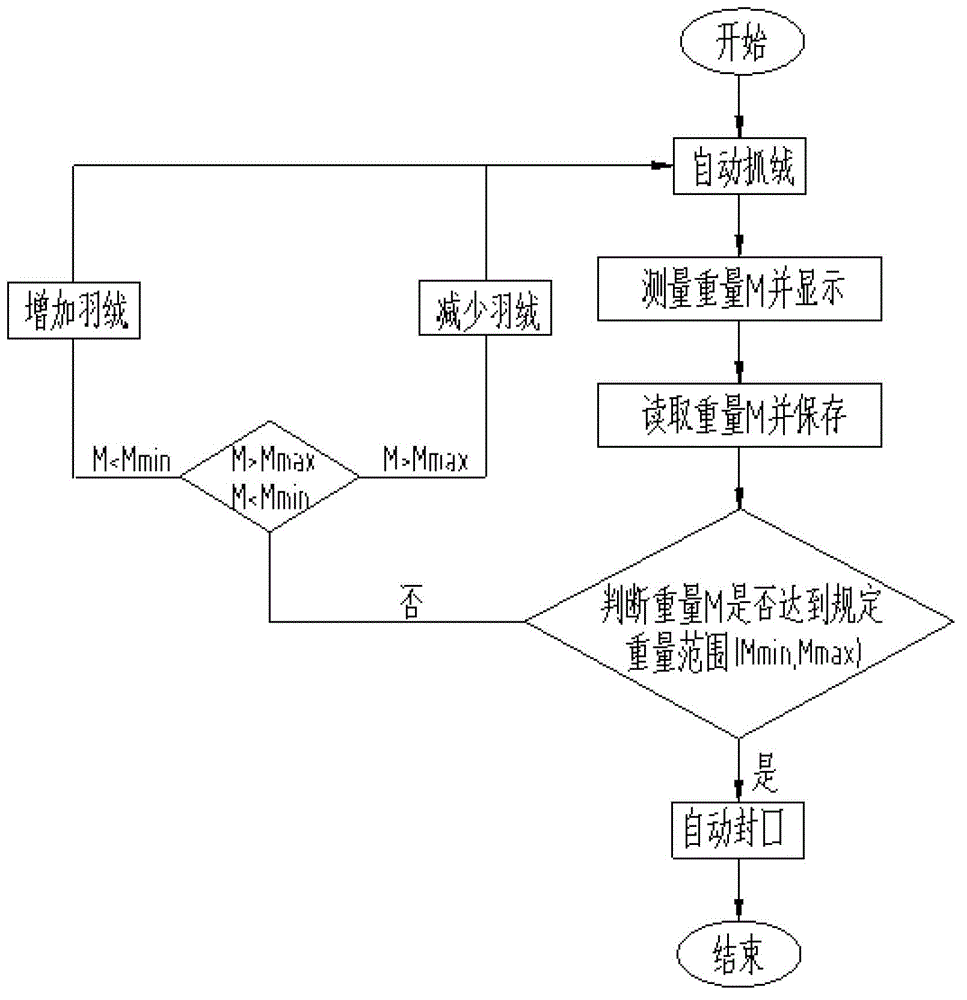

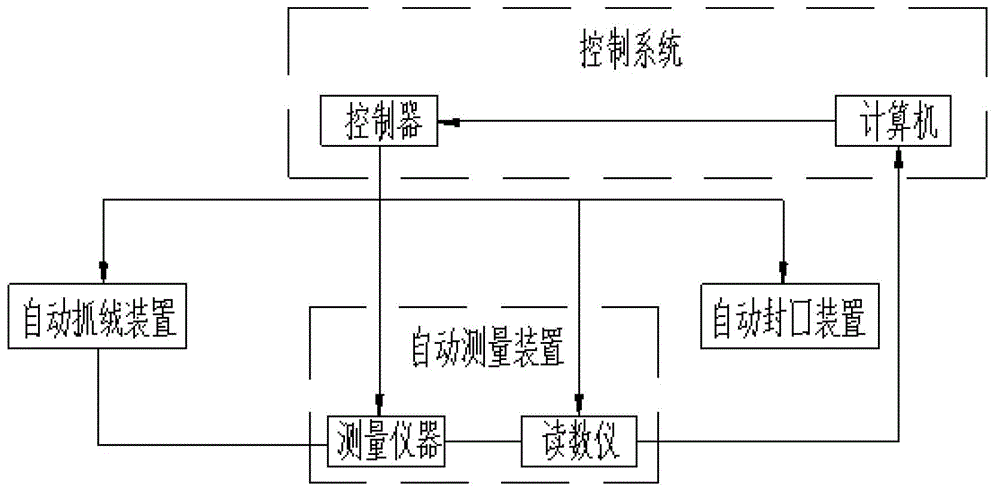

The invention discloses an automatic down filling method which comprises the following steps that a control system controls an automatic down grabbing device to grab down into a down coat part; an automatic measurement device measures and stores the weight of the down coat part filled with the down; the control system reads the weight from the automatic measurement device, judges whether the weight reaches a regulated weight range, and controls the automatic down grabbing device to carry out down increasing and decreasing operation according to a judgment result so as to enable the weight of the down coat part to reach the regulated weight range; and when the weight of the down coat part reaches the regulated weight range, an automatic sealing device carries out sealing on the down coat part. The automatic down filling method disclosed by the invention adopts a manipulator structure to carry out filling of the down, so that a worker is liberated from the heavy and dull down filling work which damages the body and the mind and when the worker is liberated, down filling efficiency is improved and labor cost of an enterprise is saved. Moreover, the invention also provides automatic down filling equipment suitable for the automatic down filling method.

Owner:福建汇达时装有限公司

A cashmere filling machine

ActiveCN109607466BAvoid cakingImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringAir blower

The invention discloses an efficient down filling machine which comprises a down filling machine main body, wherein a pipeline is mounted on one side of the down filling machine main body; a down filling port is formed in the other side of the down filling machine main body; a box body is mounted at one end of the pipeline; a down inlet is embedded into the upper part of the box body; a connectionround plate is arranged inside the box body; a rubber band is circumferentially arranged on the connection round plate; a connection pipe is embedded into the connection round plate. According to theefficient down filling machine, when the connection pipe rotates, the connection round plate is driven to rotate, so as to drive the rubber band and a short rod to rotate, and downs entering the boxbody can be flicked to avoid the hardening of the downs, scatter the downs and improve the down filling efficiency; when an air blower works, heat in a heating pipeline can be blown into the box bodythrough a through hole via an air blow pipe to play a very good air drying role and reduce moisture in the downs; an electric push rod controls a distance between a pressure plate and the down fillingport through a rotating shaft and a connection column so as to fix the down filling port and an object to be subjected to down filling.

Owner:颍上县祥盛建设管理有限公司

Feather filling method for anti-static down feather products

InactiveCN109998206AAvoid damageEffective release of frictional static electricityClothes making applicancesMaterials preparationSingle process

The invention discloses a feather filling method for anti-static down feather products. The method includes the following steps: step 1, material preparation and inspection, preparation of pre-loadedproducts, anti-static down feathers, sealing clips and a grounding wire, and inspection and cleaning of a feather filling machine, a feather filling tube, a product fixing frame, a pressure mounting platform and a sewing platform; step 2, the feather filling tube is grounded, one end of the grounding wire is connected to the ground, and one end of the grounding wire is connected onto an outer wallof the feather filling tube in an overlapped mode; step 3, fixing of the products; step 4, pre-load of the products; step 5, down feather filling; step 6, air exhausting; step 7, sewing; and step 8,cleaning. According to the feather filling method for the anti-static down feather products, a large amount of frictional static electricity accumulated in the feather filling tube can be effectivelyreleased by adding a grounding wire on the feather filling tube, and therefore, damages of static electricity to the machine and human body can be avoided; and by adopting the method of filling down feather first, exhausting and finally sewing, exhaust efficiency is improved, and the single process is easier to control, so that efficiency of down feather filling can be further improved.

Owner:THE SEA FEATHER LTD CO OF LUAN

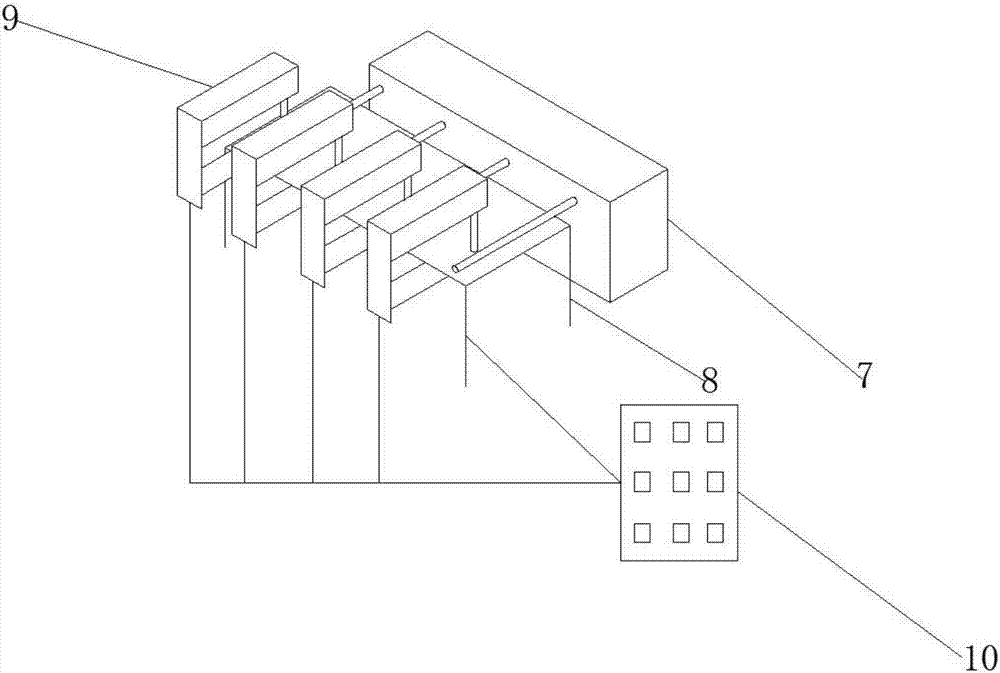

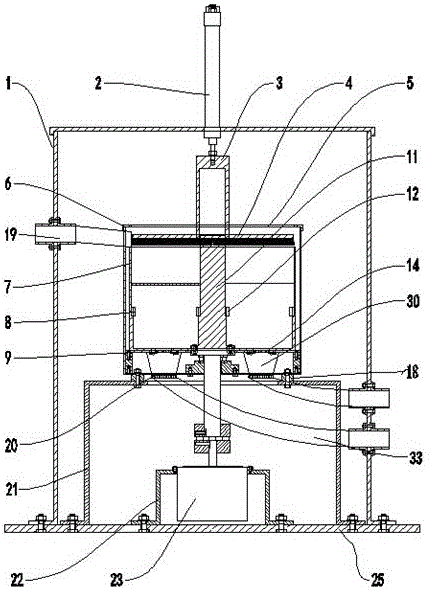

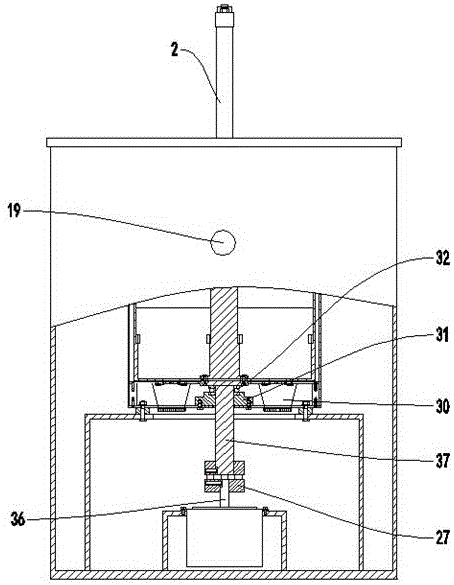

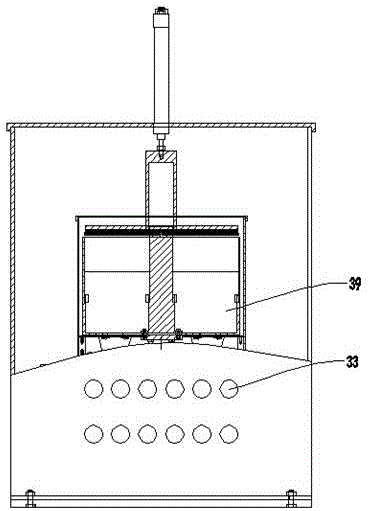

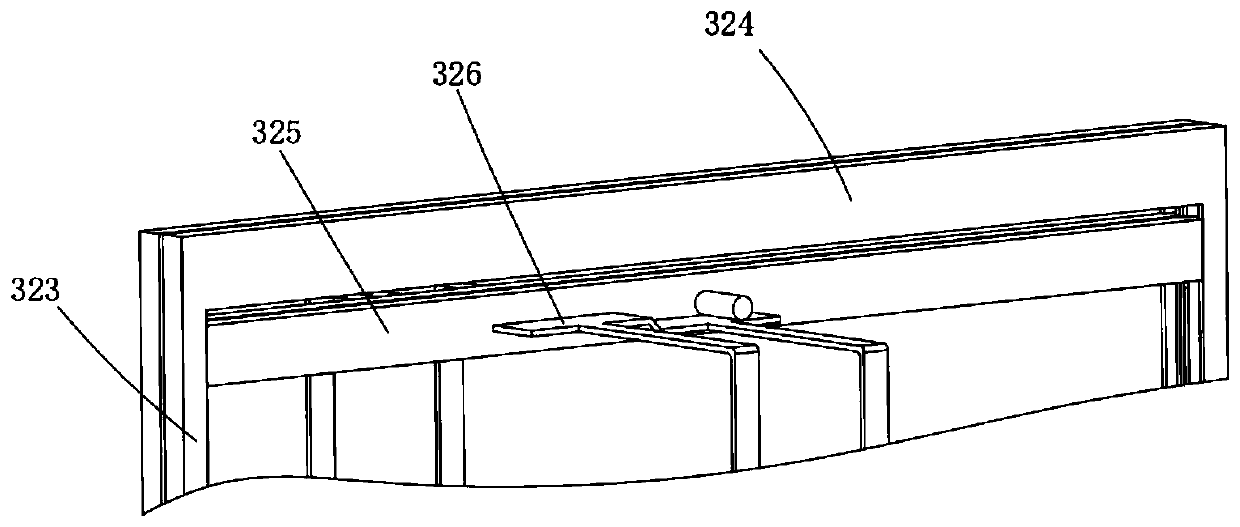

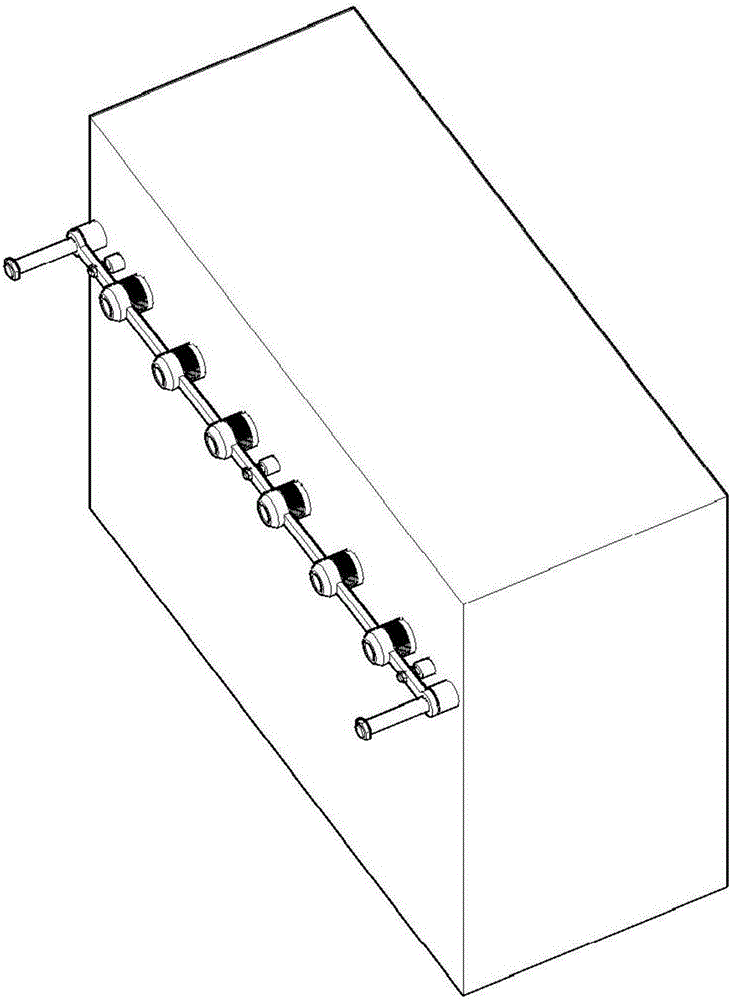

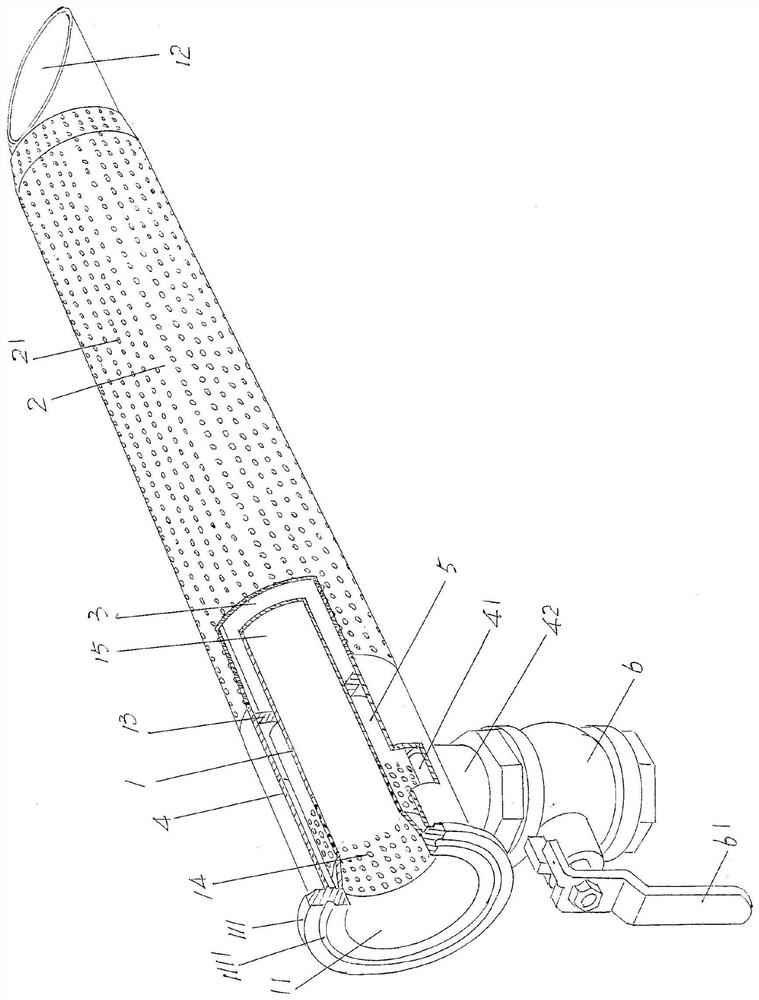

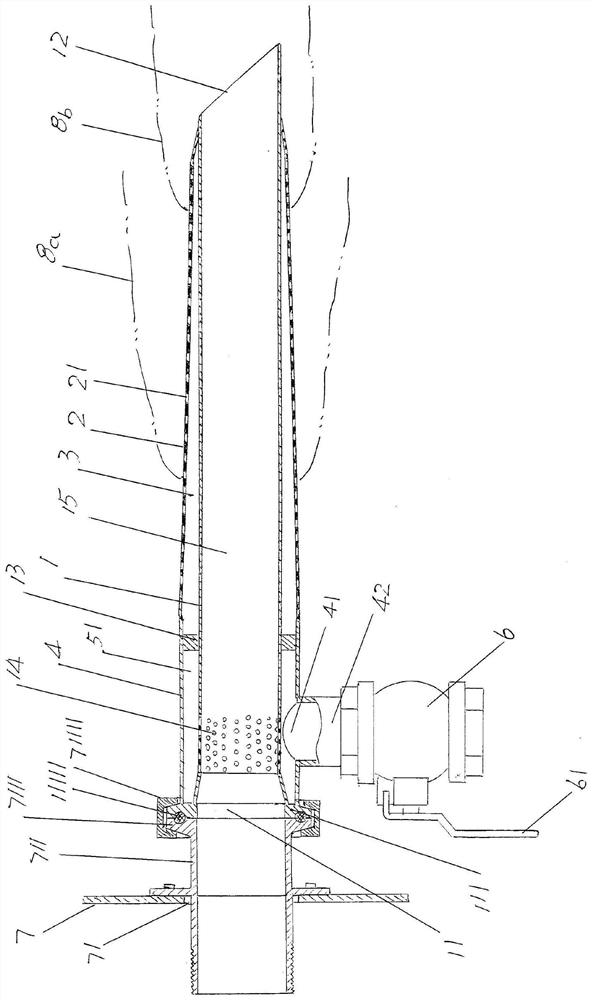

Pile discharging device capable of smoothing piles in grids of automatic pile charging device

ActiveCN106586938AImprove down filling efficiencyGood sealingUpholstery manufactureHuman healthWorking environment

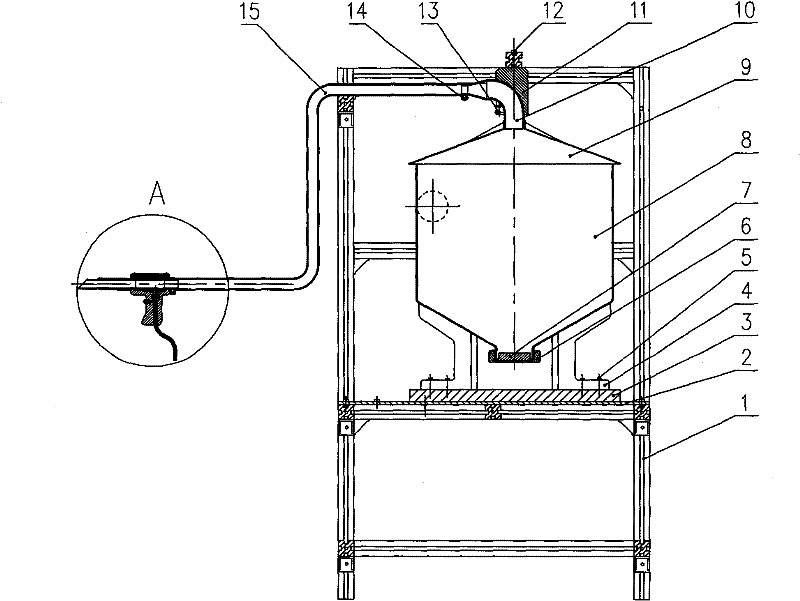

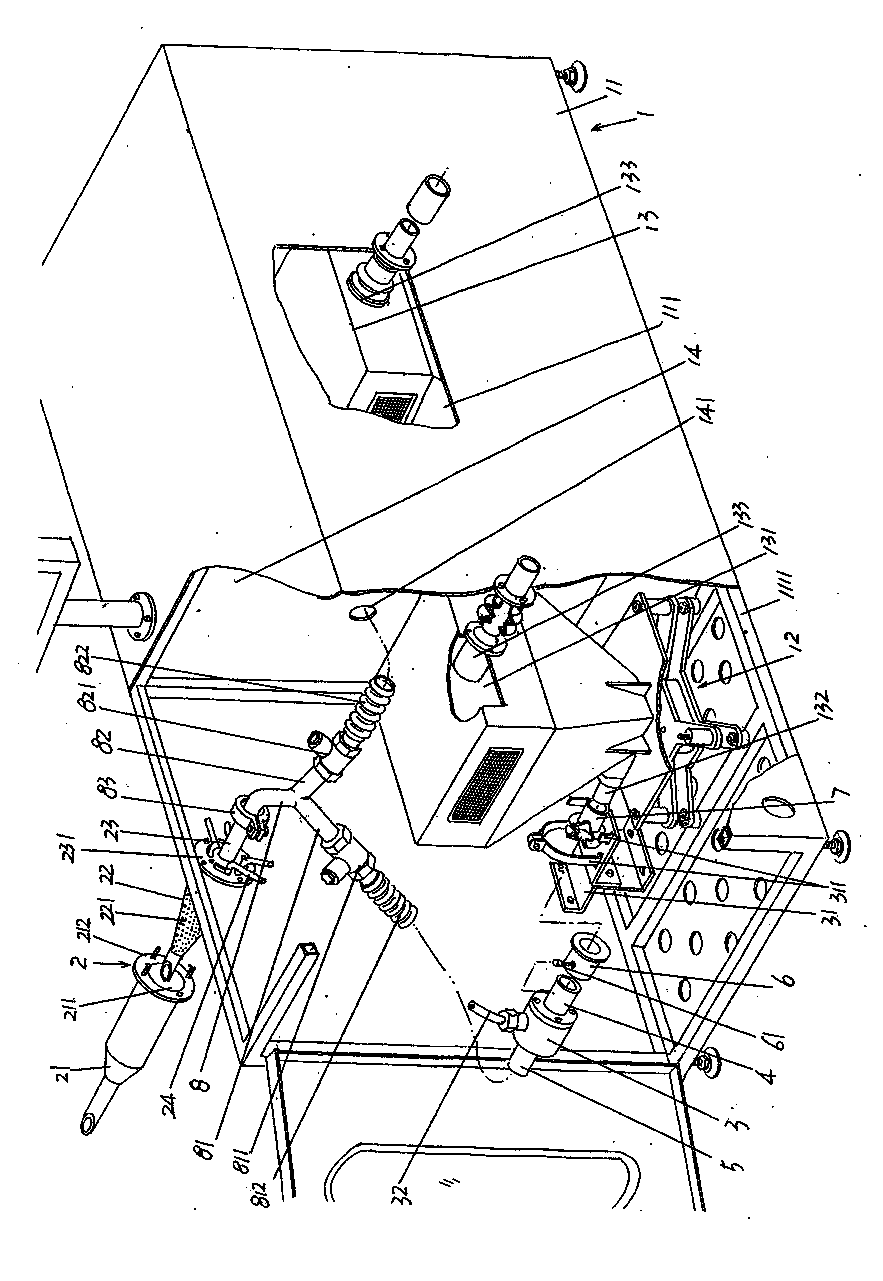

The invention discloses a pile discharging device capable of smoothing piles in grids of an automatic pile charging device. The device comprises a housing (1) and a bottom plate (25), wherein the housing (1) is fixed on the bottom plate (25) through a bolt. The device further comprises a pile feeding pipe (19), a pile discharging pipe (33), a pile feeding mechanism, a pile discharging mechanism, a driving mechanism and a smoothing device, wherein the pile feeding pipe (19) is connected with the pile feeding mechanism, the pile discharging pipe (33) is connected with the pile discharging mechanism, the driving mechanism drives the pile discharging mechanism to operate, and the smoothing device cooperates with the pile discharging mechanism for operation. The pile discharging device provided by the invention realizes automatic pile filling, the pile filling efficiency is high and is greatly improved, and the pile discharging device can automatically discharge weighted piles in the pile filling machine according to sizes of the grids; and the pile charging device has good sealing performance, thus preventing piles from drifting in air and inhaled into bodies by workers, the working environment is improved, and potential safety hazards to human health are reduced.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Down output mechanism of automatically quantitative down filling mechanism

ActiveCN103101874BMeet the down output requirementsImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringHigh pressure

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Automatic down filling control system

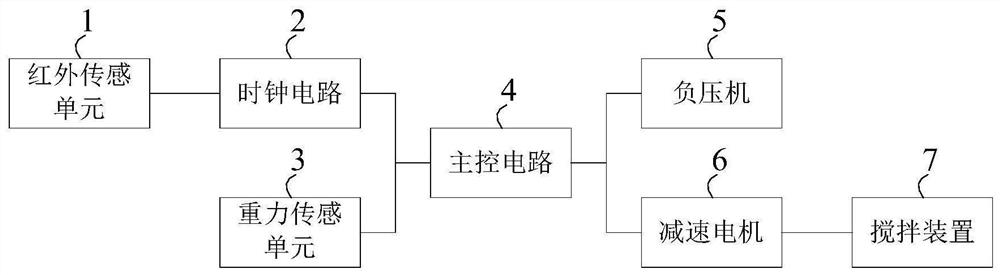

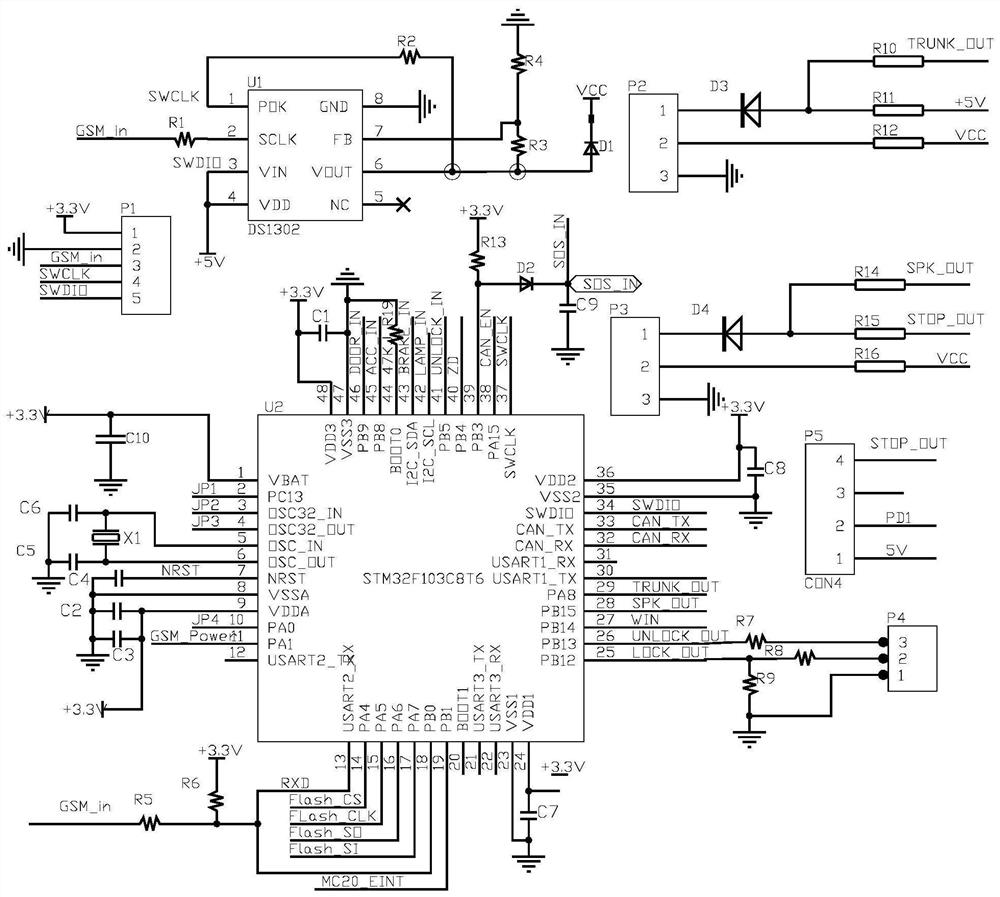

InactiveCN112255941AImprove down filling efficiencyReduce labor costsProgramme controlComputer controlControl systemElectric machinery

The invention discloses an automatic down filling control system, which comprises an infrared sensing unit, a gravity sensing unit, a clock circuit, a main control circuit, a negative pressure machine, a gear motor and a stirring device, the output end of the infrared sensing unit is electrically connected with the clock circuit, and the output end of the gravity sensing unit and the clock circuitare both electrically connected with the main control circuit. The output end of the main control circuit is electrically connected with the negative pressure machine and the gear motor, and the gearmotor is electrically connected with the stirring device. The automatic down filling control system can improve the down filling efficiency, is high in working efficiency, does not need manual down filling, and saves the labor cost.

Owner:江门市新会区荣富制衣有限公司

Pillowcase down filling equipment

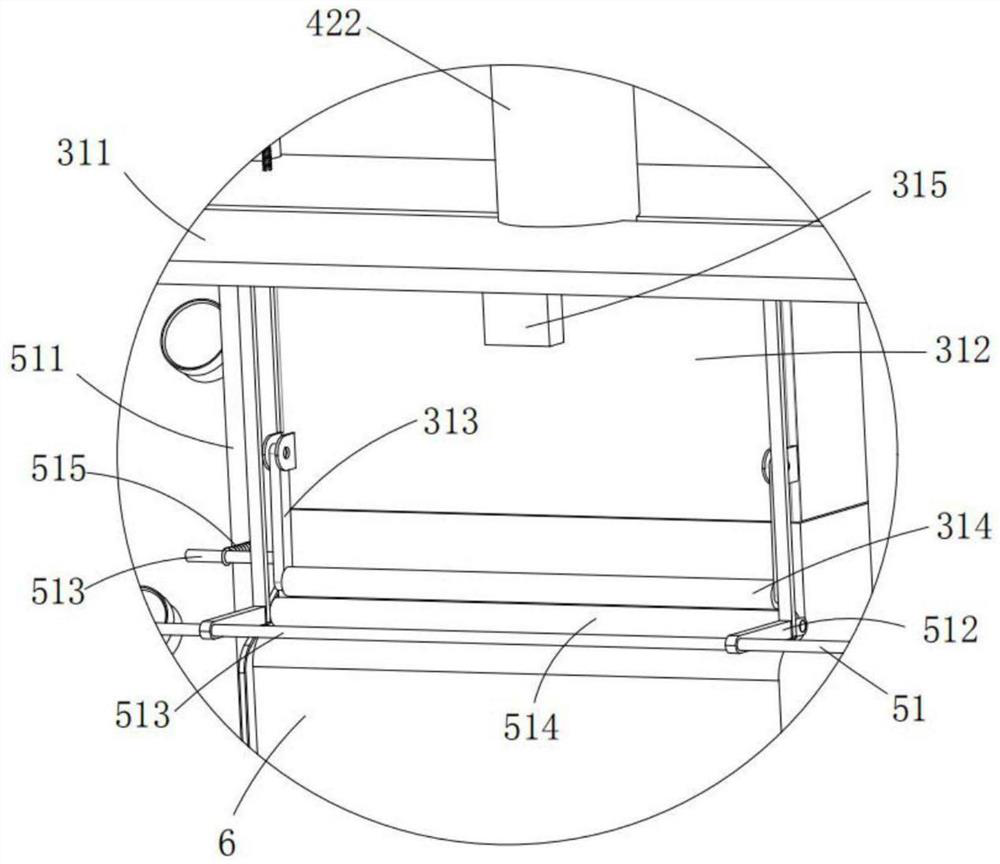

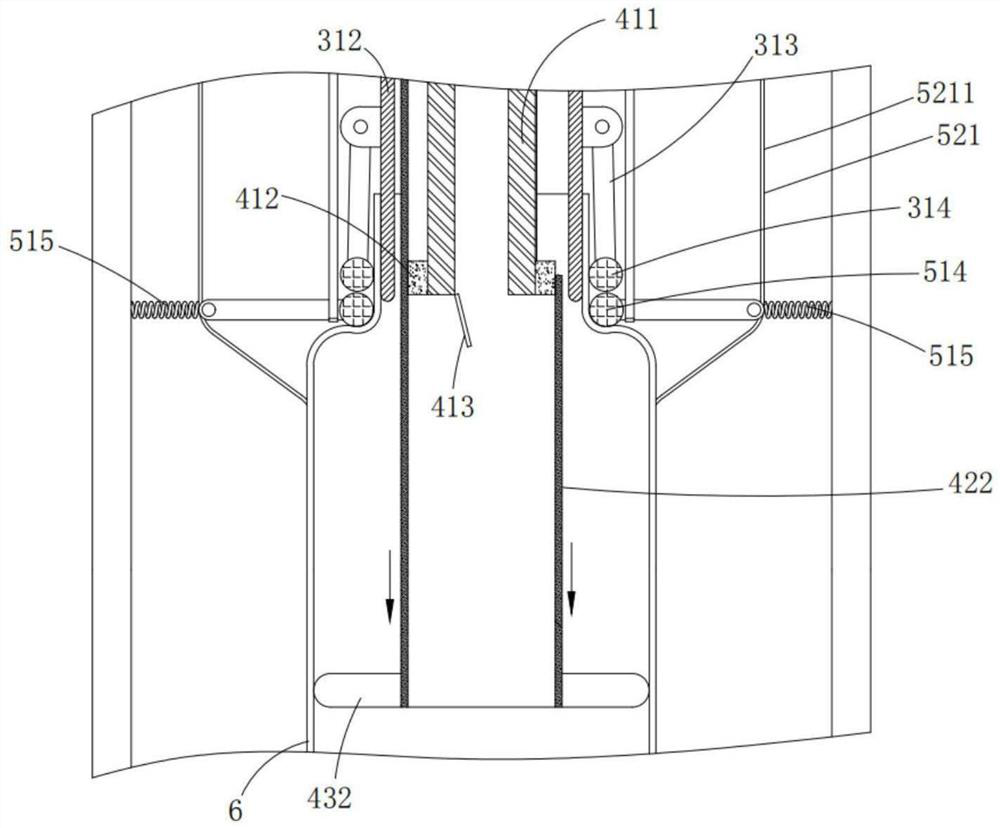

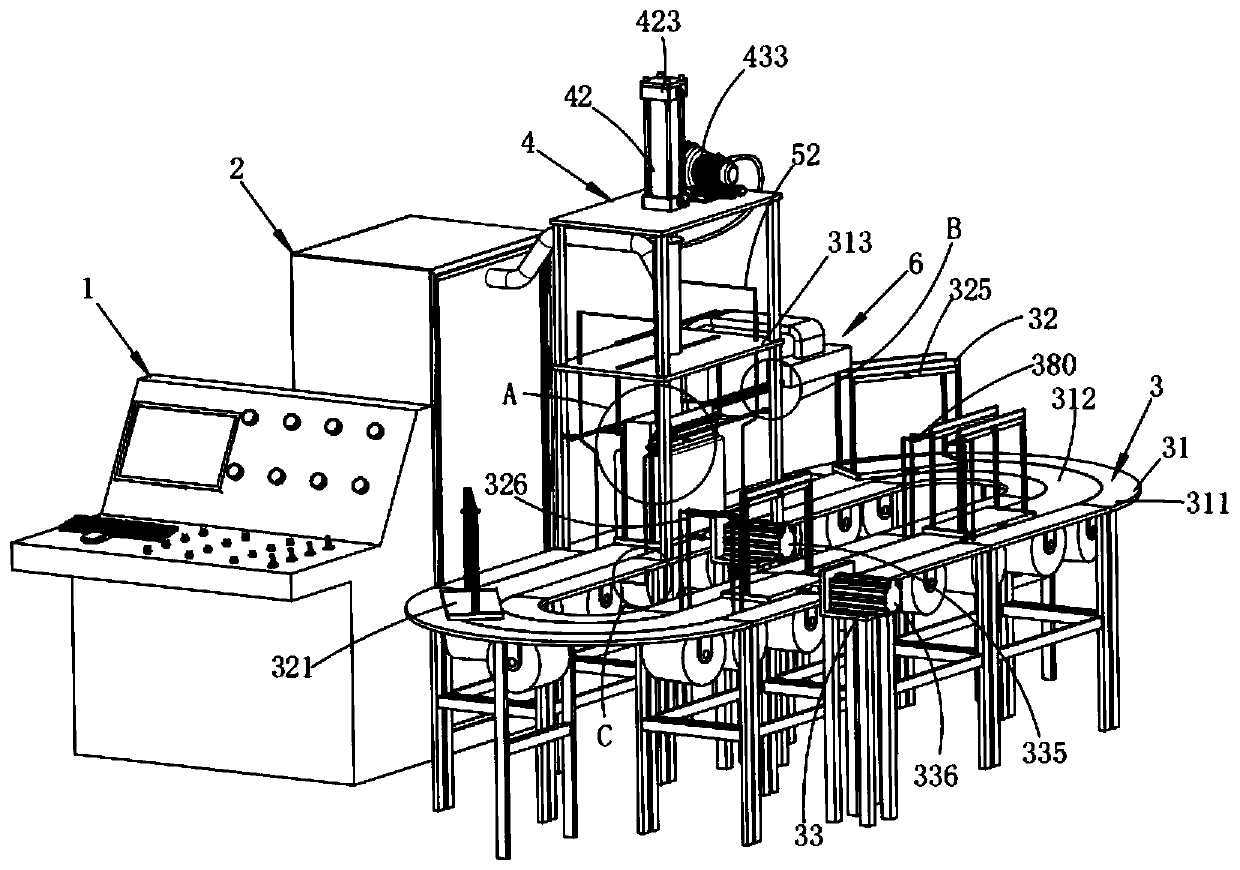

ActiveCN113120846AEasy to shapeImprove comfortPillowsUpholstery manufactureStructural engineeringMechanical engineering

Owner:杭州创元羽毛有限公司

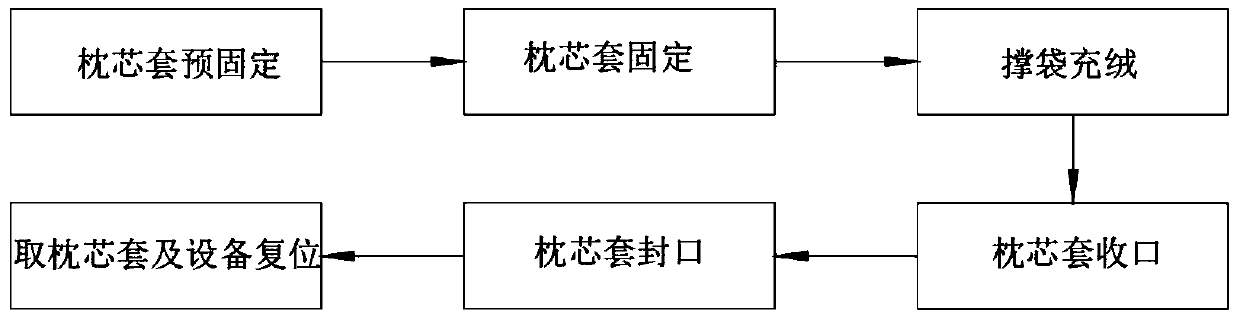

Pillow interior continuous production technology

InactiveCN111268188AIncrease productivitySimple structureWrapper twisting/gatheringSolid materialEngineeringMechanical engineering

The invention provides a pillow interior continuous production technology. The pillow interior continuous production technology comprises the following steps that a pillow interior cover is fixed in advance; the pillow interior cover is fixed; the pillow interior cover is opened and filled with down; the pillow interior cover is closed; the pillow interior cover is sealed; and a pillow interior istaken, and facilities are reset. By the adoption of the pillow interior continuous production technology, the pillow interior cover and fixing assemblies are fixed through a transverse plate, then clamping plates upwards move to enable the pillow interior cover to be outwards folded and fixed, limiting assemblies move under the action of an air cylinder a, then the pillow interior cover is opened, a press assembly stretches into the pillow interior cover, cooperates with a feeding assembly to feed the down into the pillow interior cover and presses the down to be compact, when the press assembly moves to the space above the fixing assemblies, a control assembly closes the pillow interior cover, the pillow interior cover continues to enter a sealing machine to be sealed through a guide assembly after the pillow interior cover is closed, and therefore the technical problems that in the prior art, due to the fact that the down is located in a fluffy state when down filling operation is conducted, the filling amount of the down in the pillow interior cover is reduced, and the down is prone to running away in the sealing process are solved.

Owner:李风丽

A down filling tube assembly for a down filling machine used in the production of down products

ActiveCN110775935BLow costWon't blockUpholstery manufactureDispersed particle filtrationMechanical engineeringIndustrial engineering

The invention relates to the field of production and processing equipment for down products, and discloses a down filling tube assembly for a down filling machine used in the production of down products, including a tube base, and two limiting plates are fixedly connected to one side of the top of the tube base A rotatable velvet-filling tube is provided in the movable sleeve, and a full circle of filter screen located between the two limiting plates is arranged on the velvet-filling tube. The down filling tube assembly for the down filling machine used in the production of down products, through the setting of the limit plate, the down filling tube, the filter screen, the sealing sleeve, the linkage tube, the control seat and the sealing plate, in the down filling stage, the down Injected from the lower space of the down-filling tube, the air in the down product is discharged from the filter screen on one side of the upper half of the down-filling tube, and the filter screen filters out the down mixed in the air, and the air flows out of the inner cavity of the down-filling tube Under the action of the action, it is blown to the rightmost part of the upper half of the inner cavity of the linkage tube to ensure that the down will not block the filter screen, thereby improving the outflow efficiency of air and relatively improving the down filling efficiency.

Owner:济宁晨阳制衣股份有限公司

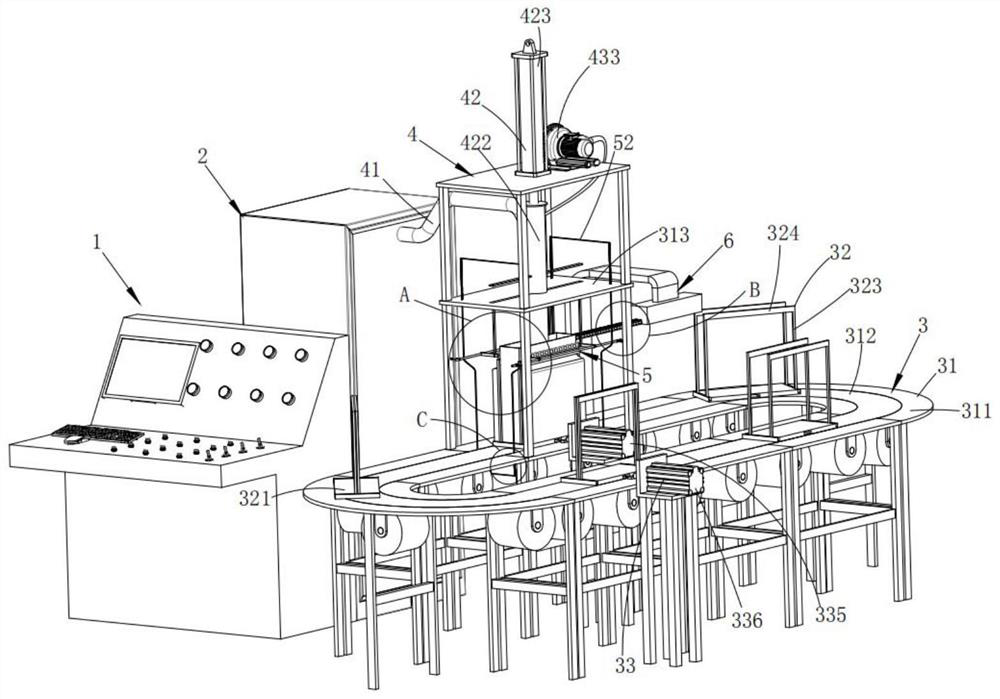

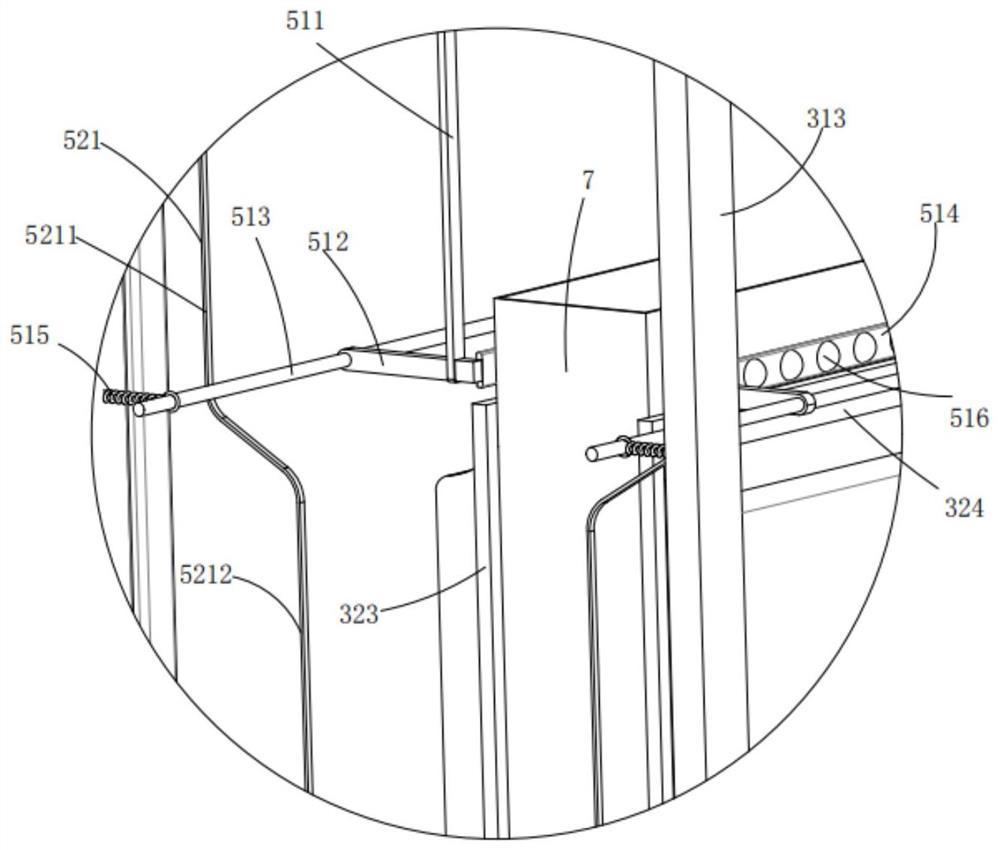

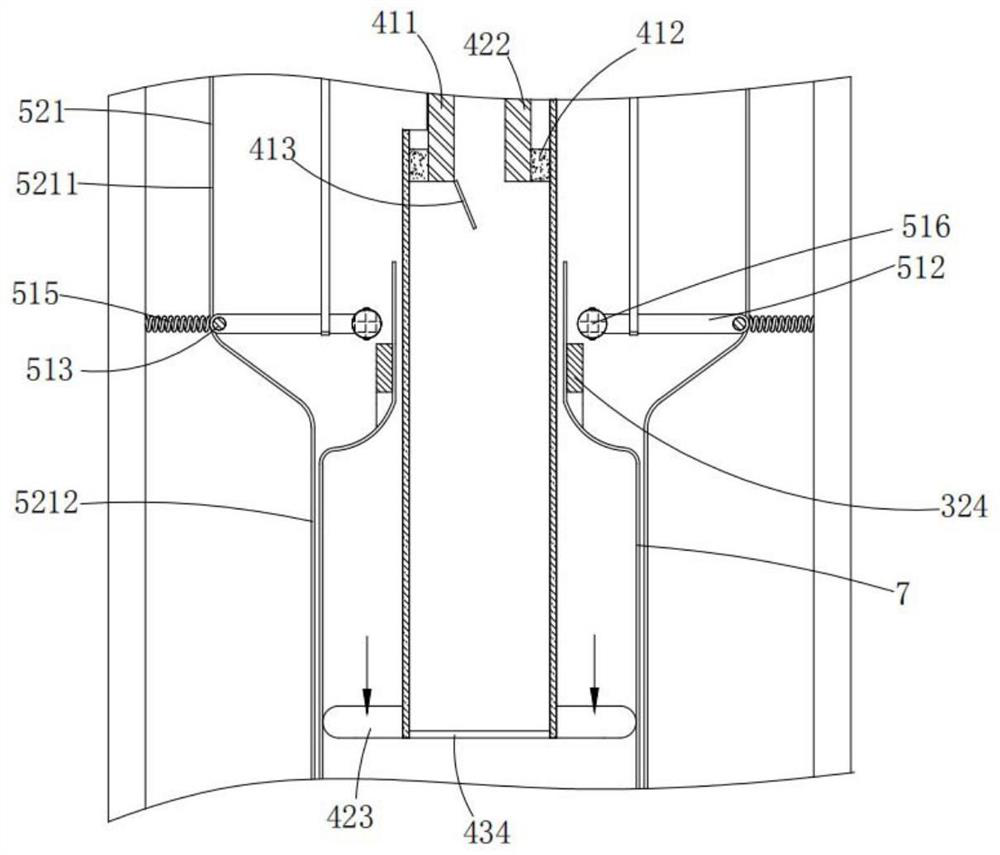

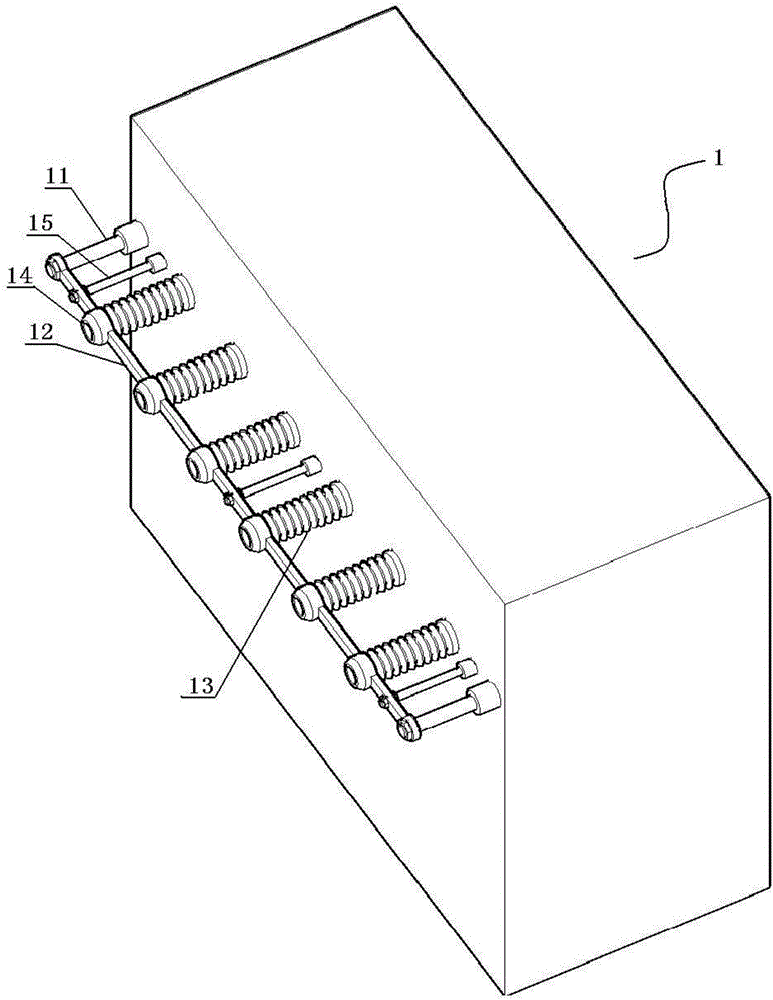

A pillow filling machine

ActiveCN111217314BImprove filling efficiencyEasy to shapeUpholstery manufactureCotton padEngineering

The invention provides a pillow filling machine, which includes a console, a down filling machine, a bag supporting device, a cotton filling device, a closing device and a sealing device, the bag supporting device includes a transport component, a fixing component and a position limiting component, and The device sealing device includes a guide assembly and a sealing machine, including a feeding assembly, a driving assembly, and a pressing assembly. The closing device includes a closing assembly and a control assembly. The present invention uses a limiting assembly to cooperate with a fixing assembly to open the pillow core, and the velvet passes through the feeding pipeline. Send the velvet between the press assembly and the pillow core, the press assembly moves up as the amount of velvet feed increases, and the press assembly keeps squeezing the velvet, and finally the press assembly moves out of the pillowcase, and drives the closing assembly to the pillowcase full of velvet It is closed and transported to the sealing machine for sealing, which solves the technical problems of low filling efficiency due to slow replacement of the pillow core when filling the pillow core, and the inability to press the down, which leads to a decrease in the amount of down filling in the pillowcase, which affects the comfort of the pillow.

Owner:QINGDAO YULINGSHAN HOME TEXTILE GRP

Down filling machine

InactiveCN105936495AEven distribution of downImprove down filling efficiencyUpholstery manufactureThreaded pipeEngineering

Owner:CHANGLE LIZHI IND DESIGN CO LTD

A kind of filling method of down jacket down material

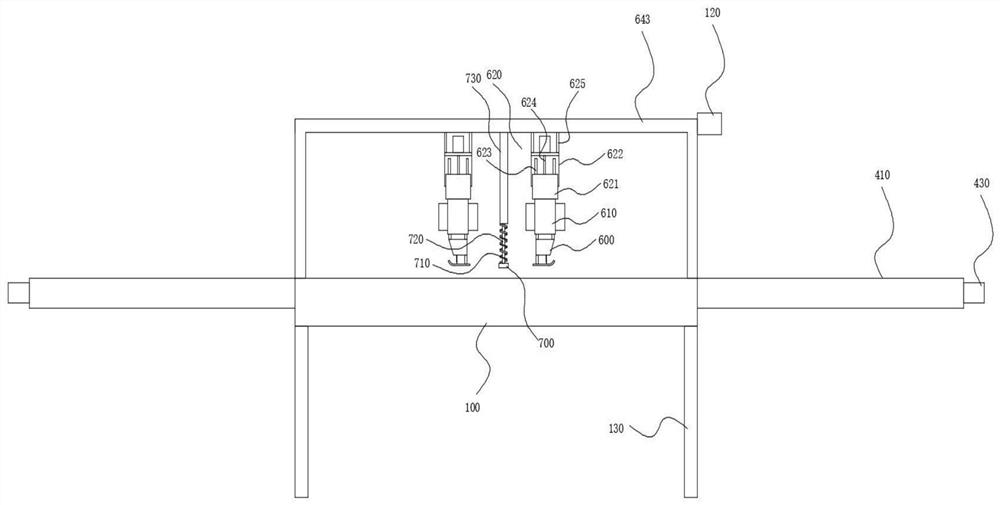

ActiveCN113548634BImprove down filling efficiencyUpholstery manufactureSewing-machine casingsEngineeringSewing machine

The invention discloses a method for filling down material for down jackets, and relates to the technical field of down jacket processing. The horizontal sewing lines of the down-filled squares on the down quilt are stitched together, and the longitudinal sewing lines of the down-filled squares in the middle of the down quilt are stitched together; Place the down quilt in the positioning groove; then drive the first down-filling tube and the second down-filling tube into the down-filling grid through the down-filling tube moving component, and the elastic tensioning component pulls the first slide bar and the second slide bar , so that the duvet is tightened: then a certain amount of down is poured into the grid through the first down filling tube and the second down filling tube; then the longitudinal moving component and the horizontal moving component cooperate with the lifting component to drive the single head of the arm sewing machine to move, The longitudinal sewing thread of the down-filled grid can be sewn by a single head of multiple arm-type sewing machines; the down-filling of the duvet can be completed by analogy; the present invention has the advantages of convenient use, high down-filling efficiency, and prevention of down-running advantage.

Owner:安徽宜民服饰股份有限公司

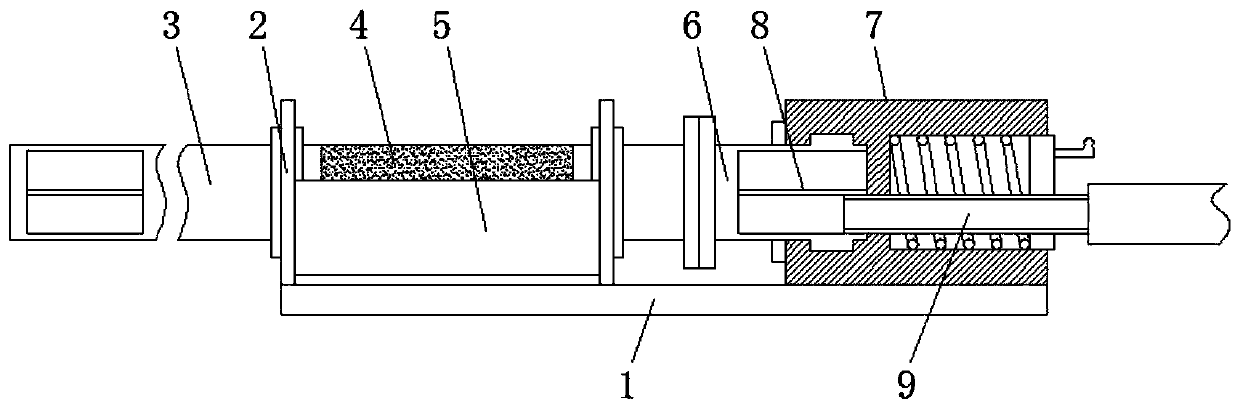

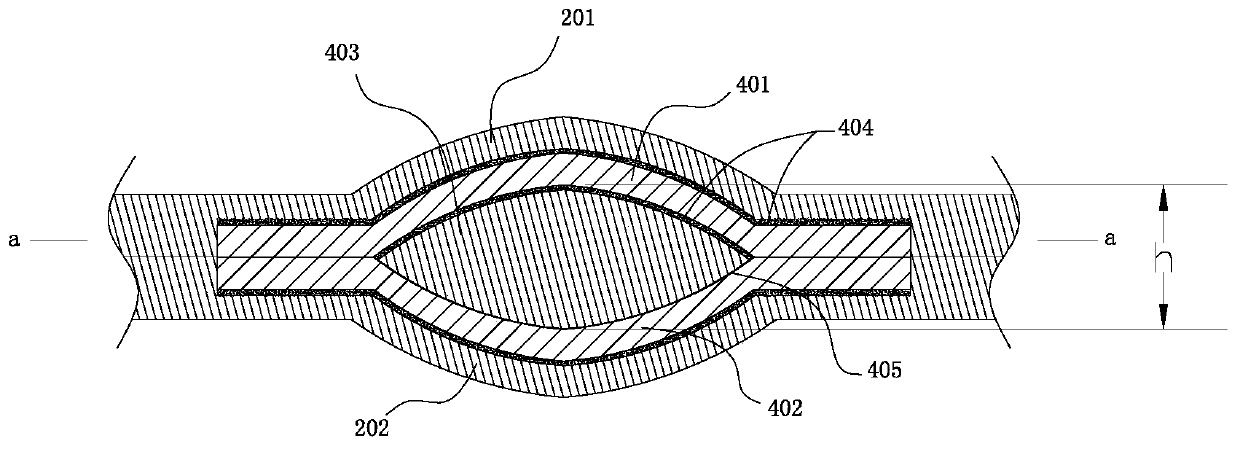

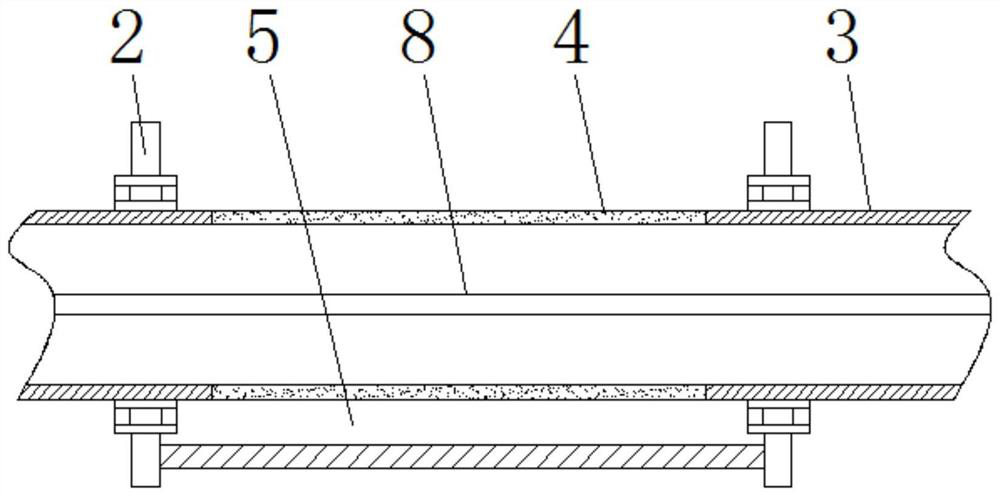

Down filling structure for down filling machine

ActiveCN107522160AAvoid bulgingWon't clogUpholstery manufactureClothes making applicancesControl valvesAerospace engineering

The invention discloses a down filling structure for a down filling machine, which comprises a down feeding pipe; the left end of the down feeding pipe is provided with a down inlet of the down feeding pipe, and the right end thereof is provided with a down outlet of the down feeding pipe; an air leaking pipe is located at outside of the down feeding pipe, its left and right ends are sealed; an air leaking cavity is arranged between the inner wall of the air leaking pipe and the outer wall of the down feeding pipe, and the air leaking cavity is connected to outside. The down filling structure is characterized in that a space ring is fixed on the outer wall of the down feeding pipe, an advanced air leaking cavity sleeve pipe is arranged between the down inlet of the down feeding pipe and the space ring; the right end face of the advanced air leaking cavity sleeve pipe is mutually jointed with the left end face of the air leaking pipe at the position of the space ring; the space between the inner wall of the advanced air leaking cavity sleeve pipe and the outer wall of the down feeding pipe is formed to be an advanced air leaking cavity, and the advanced air leaking cavity is connected with the down feeding pipe; an advanced air leaking opening is arranged on the advanced air leaking cavity sleeve pipe, and connected with the advanced air leaking cavity and provided with an advanced air leaking control valve; the advanced air leaking cavity is separated from the air leaking cavity by the space ring. The down filling structure avoids the heaving of a feather cylinder and improves the down filling efficiency; besides, the down filling structure can avoid that the path from the down inlet of the down feeding pipe to the down outlet of the down feeding pipe is too long; the structure is simple; the blockage of the advanced leaking air control valve cannot be generated.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Automatic down filling method and automatic down filling equipment

InactiveCN103844423BReduce labor intensityReduce the chance of diseaseClothes making applicancesMeasurement deviceControl system

The invention discloses an automatic down filling method which comprises the following steps that a control system controls an automatic down grabbing device to grab down into a down coat part; an automatic measurement device measures and stores the weight of the down coat part filled with the down; the control system reads the weight from the automatic measurement device, judges whether the weight reaches a regulated weight range, and controls the automatic down grabbing device to carry out down increasing and decreasing operation according to a judgment result so as to enable the weight of the down coat part to reach the regulated weight range; and when the weight of the down coat part reaches the regulated weight range, an automatic sealing device carries out sealing on the down coat part. The automatic down filling method disclosed by the invention adopts a manipulator structure to carry out filling of the down, so that a worker is liberated from the heavy and dull down filling work which damages the body and the mind and when the worker is liberated, down filling efficiency is improved and labor cost of an enterprise is saved. Moreover, the invention also provides automatic down filling equipment suitable for the automatic down filling method.

Owner:福建汇达时装有限公司

Down filling machine weighing box with buffer function and down filling method thereof

ActiveCN104760918BPlay a buffer roleImprove down filling efficiencyUpholstery manufactureWeighing apparatus for materials with special property/formEngineeringCrate

The invention discloses a weighing box of a woolen filling machine with buffer function. The weighing box comprises several metering transmission systems; every system comprises a weighing mechanism, a metering hopper and a buffer box; the weighing mechanism weighs woolens in the metering hopper; a first woolen inlet and a second woolen outlet are arranged on the metering hopper; the first woolen inlet is connected with a woolen storage box through a first woolen conveying pipeline, a second woolen inlet and a second woolen outlet are arranged on the buffer box; the first woolen outlet of the metering hopper is connected with the second woolen inlet on the buffer box through the second woolen conveying pipeline; the woolens in the metering hopper enter the buffer box, and the second woolen outlet on the buffer box is connected with third woolen conveying pipelines; all third woolen conveying pipelines of the metering conveying system are linked in parallel and then connected with a woolen filling head; conveying devices for generating the woolen conveying power are arranged on the second woolen conveying pipeline and the third woolen conveying pipelines on the metering conveying system; the weighing box is additionally provided with the buffer box, and can play a buffer effect in weighing time; and thereby, the metering woolen filling efficiency is effectively promoted.

Owner:CHANGSHU BEALEAD AUTO MACHINERY

The structure of the filling tube for the filling machine

ActiveCN107522160BAvoid bulgingWon't clogUpholstery manufactureClothes making applicancesEngineeringControl valves

A fleece-filling tube structure for a fleece-filling machine, comprising a fleece-passing tube, a fleece-passing tube inlet port at the left end and a fleece-passing tube outlet port at the right end; a venting tube is located outside the fleece-passing tube and the left and right ends are closed, and the ventilating tube is closed. There is a deflation cavity between the inner wall of the trachea and the outer wall of the velvet tube, and the deflation cavity is communicated with the outside world. Features: A spacer is fixed on the outer wall of the velvet tube. The right end face of the pre-deflation chamber sleeve and the left end face of the air deflation pipe are joined to each other at the position of the spacer. The cavities are communicated with each other, a pre-bleed port is arranged on the sleeve of the pre-bleed cavity, the pre-bleed hole is communicated with the pre-bleed cavity and a pre-bleed control valve is arranged, and the pre-bleed cavity and the cavity are separated by a spacer. Avoid the down bobbin bulging, improve the down filling efficiency; avoid the path from the down tube inlet to the down tube outlet too long; the structure is simple; the pre-vent control valve will not be blocked.

Owner:SUZHOU BIYANGTE CLOTHING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com