Down filling structure for down filling machine

A technology of down filling machine and tube structure, which is applied in the field of down product filling equipment, can solve the problems of affecting down filling efficiency, affecting down filling speed, and bulging of down bobbins, so as to ensure the down filling efficiency, the overall structure is simple, and it is beneficial to The effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

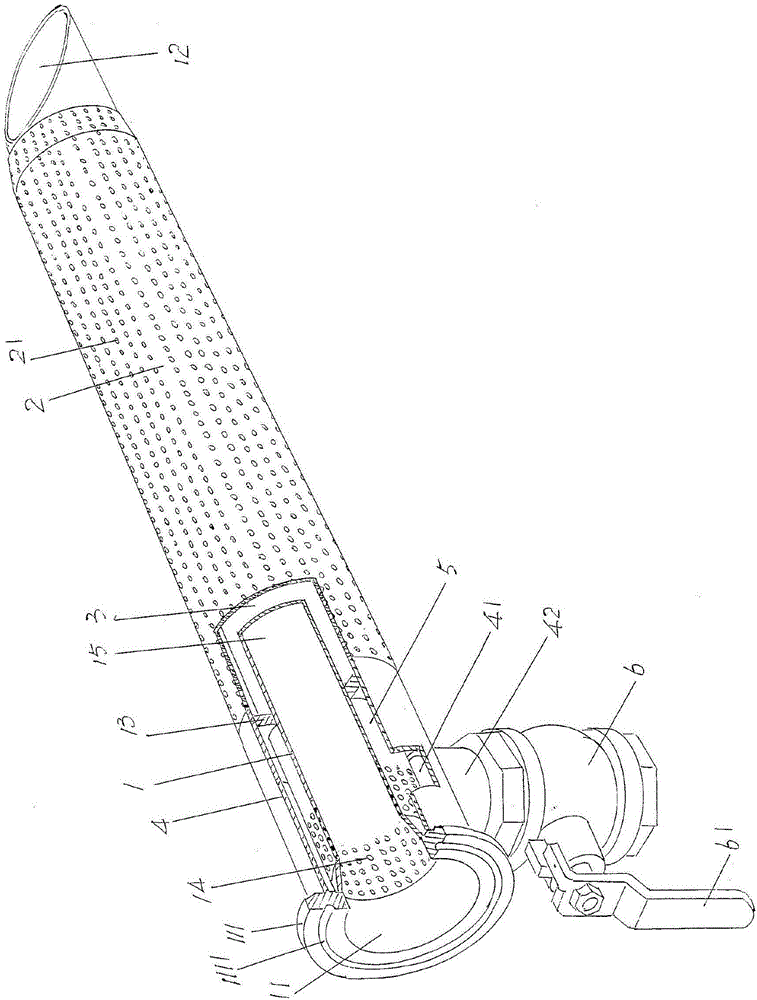

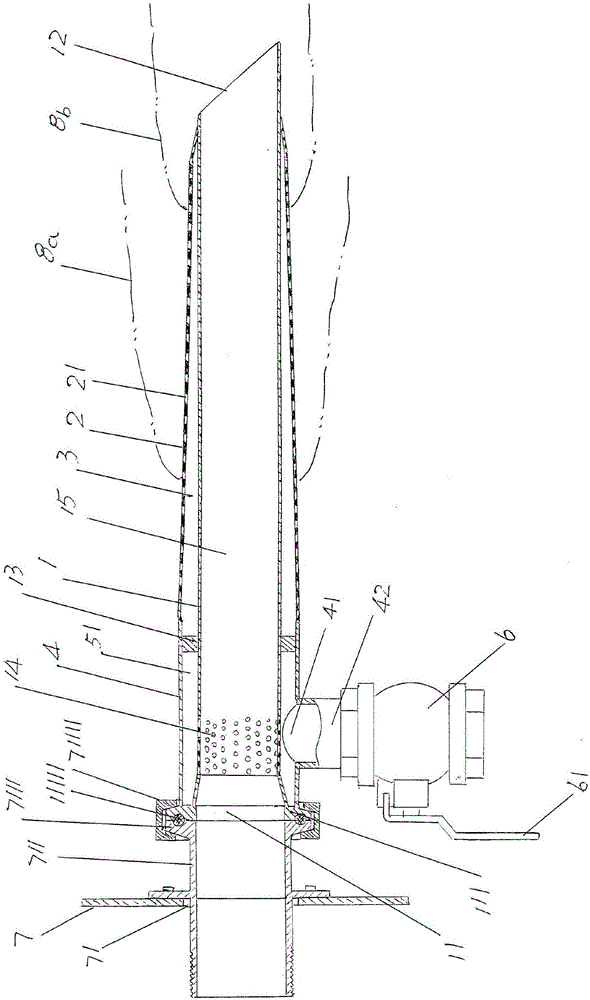

[0024] See figure 1 , Shows a velvet tube 1, at the left end of the velvet tube 1 is formed with a velvet tube inlet 11, and at the right end of the velvet tube 1 is formed with a velvet tube outlet 12; The trachea 2, the vent tube 2 is located outside the aforementioned velvet tube 1 and the left and right ends of the vent tube 2 are closed. A vent cavity 3 is formed between the inner wall of the vent tube 2 and the outer wall of the velvet tube 1, the vent chamber 3 The vent pipe vent hole 21 opened on the vent pipe 2 communicates with the outside.

[0025] As the technical point of the technical solution provided by the present invention: on the outer wall of the aforementioned velvet tube 1 and at a position corresponding to the left end of the aforementioned vent tube 2, a spacer ring 13 is fixed around the circumferential direction of the velvet tube 1, and A pre-venting chamber sleeve 4 is arranged between the aforementioned velvet tube fleece inlet 11 and the spacer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com